Method for preparing hydrophobic organic framework solid base catalyst

A solid base catalyst and organic framework technology, applied in the field of material chemistry, can solve the problems of active center deactivation, low specific surface area, difficult regeneration, etc., achieve good adsorption capacity, increase specific surface area, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Firstly, the mesoporous polydivinylbenzene material, namely PDVB-VI, was synthesized with ethyl acetate solvent.

[0021] Add 2g of divinylbenzene into a reaction kettle containing 0.065g of azobisisobutyronitrile, 30ml of tetrahydrofuran, and 0.467ml of 1-vinylimidazole, take it out after 1 day of hydrothermal treatment at 100°C, open the cover, and evaporate the solvent at room temperature to obtain A new type of solid base material (PDVB-VI) copolymerized with polydivinylbenzene and imidazole with high specific surface area and rich mesoporous structure.

Embodiment 2

[0023] Evaluation of Catalytic Performance and Its Comparison with Traditional Catalytic Materials

[0024] Triglyceryl palmitate and methanol transesterification reaction conditions: Add 0.84g triglyceryl palmitate to a round bottom flask and melt at 65°C, then quickly add 3.76mL methanol, 0.05g catalyst, react at 65°C, 1h , 3h later sampling analysis, methyl dodecanoate as the internal standard.

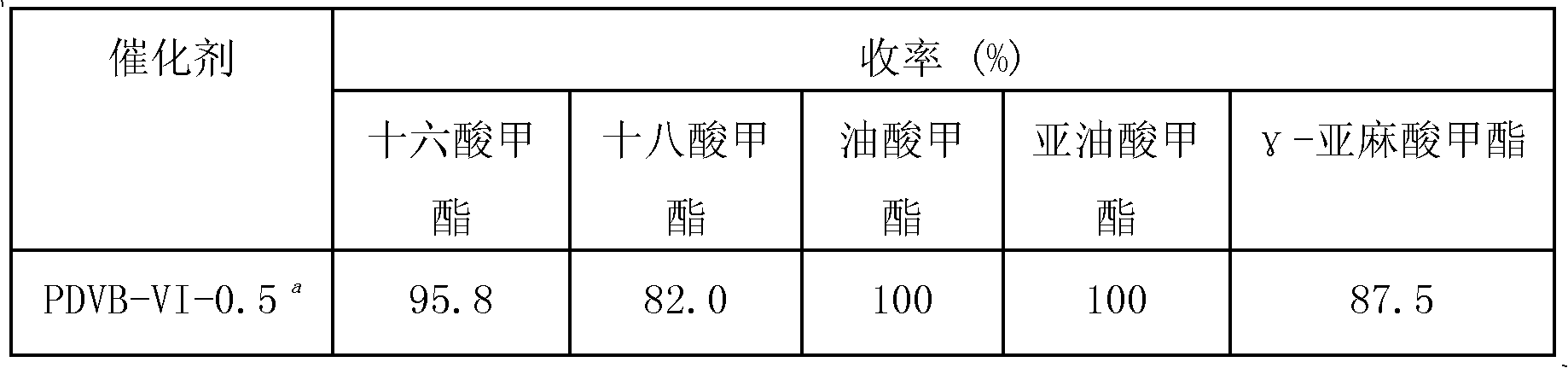

[0025] The transesterification reaction conditions of cloud mustard oil and methanol: 0.1g catalyst, 2.35mL cloud mustard oil, 5mL methanol were mixed evenly, and then the reaction was completed at 65°C for 2h, and methyl dodecanoate was used as the internal standard.

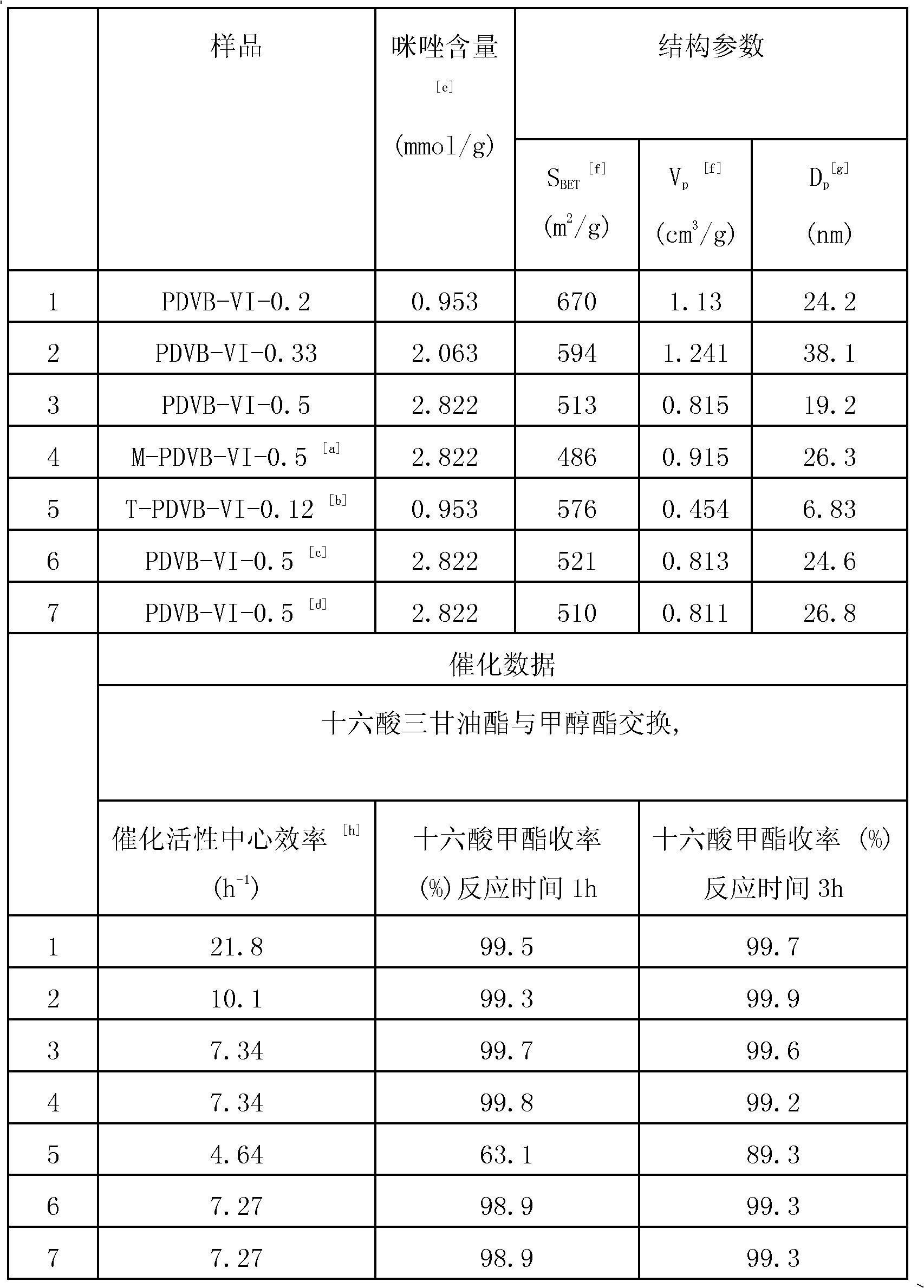

[0026] Supplementary Table 1 provides the material structure parameters. It can be seen that the novel solid base has a rich nanopore structure and a large specific surface area and pore volume; the conversion rate is close to 100% after catalyzing the transesterification reaction for 1 hour, indicating that the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com