Preparation method of reconstituted tobacco

A technology for reconstituted tobacco leaves and tobacco stems, which is applied in the preparation of tobacco, tobacco, and tobacco treatment. It can solve the problems of difficult nanomaterials to effectively adsorb, affect the quality of reconstituted tobacco leaves, and cannot change the microstructure. It achieves excellent stability and repeatability. Sexuality, obvious fragrance-enhancing effect, effect of unique stylistic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

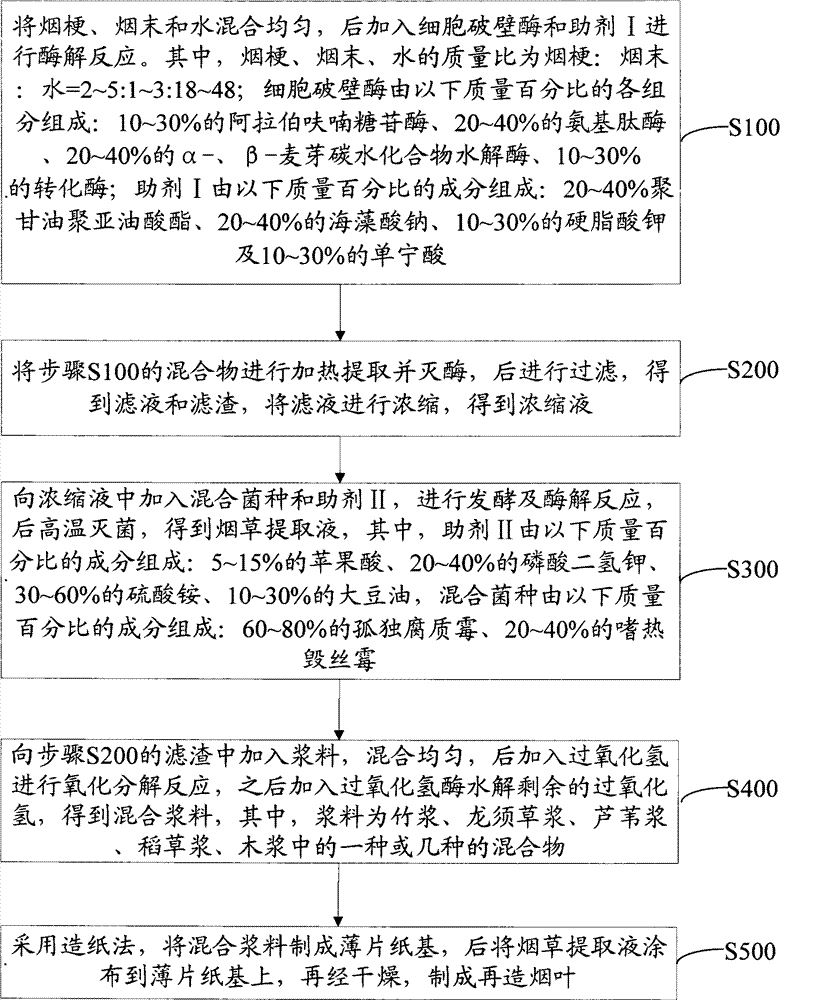

[0025] see figure 1 , the preparation method of the reconstituted tobacco leaf of one embodiment, comprises the following steps:

[0026] Step S100, uniformly mix the tobacco stems, tobacco powder and water, and then add cell wall breaking enzyme and auxiliary agent I to carry out enzymatic hydrolysis reaction. Wherein, the mass ratio of tobacco stem, tobacco powder and water is tobacco stem: tobacco powder: water=2~5:1~3:18~48; the cell wall-breaking enzyme is composed of the following components in mass percentage: 10~30 % arabinofuranosidase, 20-40% aminopeptidase, 20-40% α-, β-malt carbohydrate hydrolase, 10-30% invertase; auxiliary agent I consists of the following components in mass percentage : 20-40% polyglycerol polylinoleate, 20-40% sodium alginate, 10-30% potassium stearate and 10-30% tannic acid.

[0027] Among them, the quality of the cell wall-breaking enzyme is 0.5-2‰ of the total dry weight of tobacco stems and tobacco dust, and the length of the tobacco stem...

Embodiment 1

[0048] A method for preparing reconstituted tobacco leaves, comprising the following steps:

[0049] (1) Mechanically crush the tobacco stems to a length of 20mm, mix 500g of tobacco stems, 250g of tobacco powder, and 4500g of water evenly, raise the temperature to 30°C, adjust the pH to 4.0 with citric acid, and then add 0.375g of cell crushing Wall enzyme and 0.15 g of auxiliary agent I were used for enzymolysis reaction, and the enzymolysis time was 2 hours.

[0050] Among them, the cell wall breaking enzyme is composed of the following components in mass percentage: 20% arabinofuranosidase, 30% aminopeptidase, 30% α-, β-malt carbohydrate hydrolase, 20% invertase . The auxiliary agent I is composed of the following components in mass percentage: 30% polyglycerol polylinoleate, 30% sodium alginate, 20% potassium stearate and 20% tannic acid.

[0051] (2) Heat the mixture in step (1) to extract and inactivate the enzyme, then filter with a filter membrane to obtain the filt...

Embodiment 2

[0059] A method for preparing reconstituted tobacco leaves, comprising the following steps:

[0060] (1) Mechanically crush the tobacco stems to a length of 25mm, mix 750g of tobacco stems, 500g of tobacco powder, and 7500g of water evenly, raise the temperature to 40°C, adjust the pH to 5.0 with citric acid, and then add 1.25g of cell crushing Wall enzyme and 0.375g of auxiliary agent I carry out the enzymolysis reaction, and the enzymolysis time is 1h.

[0061] Among them, the cell wall breaking enzyme is composed of the following components in mass percentage: 20% arabinofuranosidase, 30% aminopeptidase, 30% α-, β-malt carbohydrate hydrolase, 20% invertase . The auxiliary agent I is composed of the following components in mass percentage: 30% polyglycerol polylinoleate, 30% sodium alginate, 20% potassium stearate and 20% tannic acid.

[0062] (2) The mixture in step (1) is heated and extracted to inactivate the enzyme, and then filtered with a filter membrane to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com