Preparation and applications of surfactant for alcohol amide-sulfate composite type alkali-free oil displacement

A surfactant and sulfate technology, used in the preparation of sulfates, drilling compositions, chemical instruments and methods, etc., can solve the problems of poor salt tolerance of anionic surfactants, and reduce the oil/water interfacial tension. , the effect of excellent salt resistance and excellent oil/water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of cocoic acid monoethanolamide polyoxyethylene ether sulfate

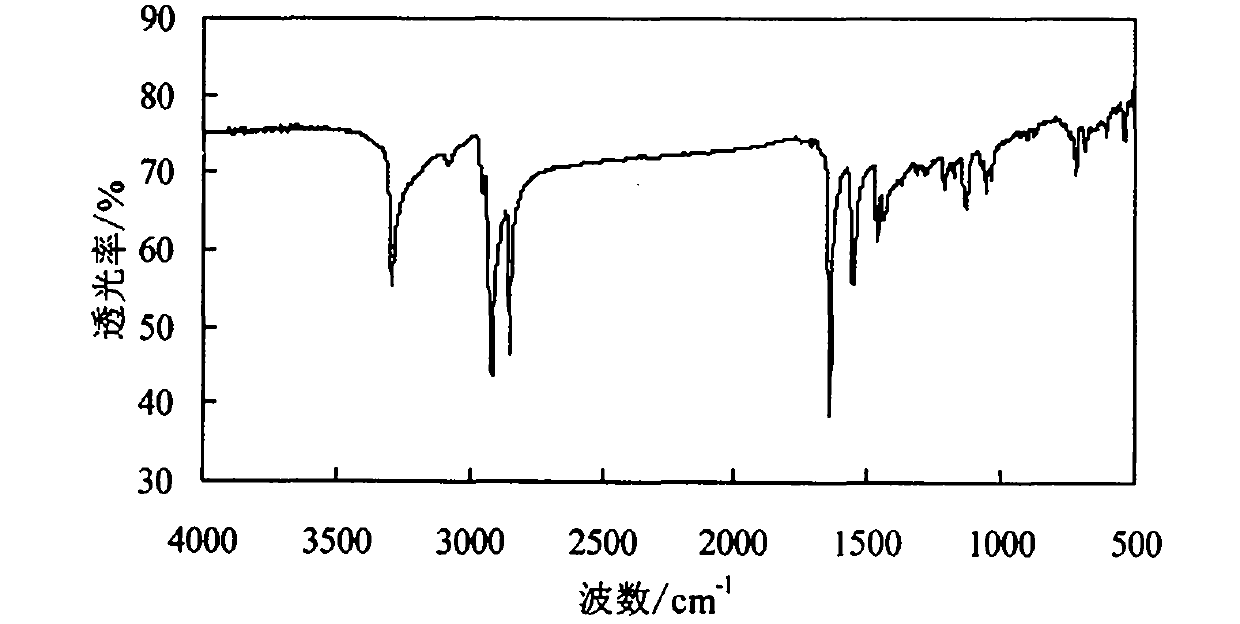

[0025] Using commercially available cocoic acid monoethanolamide (CMEA, content 97%) as raw material, ethylene oxide (EO) was added in a 0.5L high-pressure reactor (Weihai Self-Control Reactor Co., Ltd.). The feeding amount of CMEA is 100-150g, the catalyst is KOH, and the dosage is 0.5% of the mass of CMEA. Calculate the amount of EO added based on the total number of ethylene oxide per molecule n=2~5, press EO into with nitrogen, and react at 150~180°C until the pressure (gauge pressure) drops to zero. figure 1 is a product CMEA-EO 2 Infrared spectrum chart.

[0026] Add 10.3g CMEA-EO to a 250mL four-neck flask 2 , chloroform 100ml, start the stirrer and stir until CMEA-EO 2 Dissolve completely, then slowly add chlorosulfonic acid dropwise under stirring, keep chlorosulfonic acid / CMEA-EO 2 The molar ratio is 1.2:1, and the temperature is kept at about 20°C during the dropping process. Th...

Embodiment 2

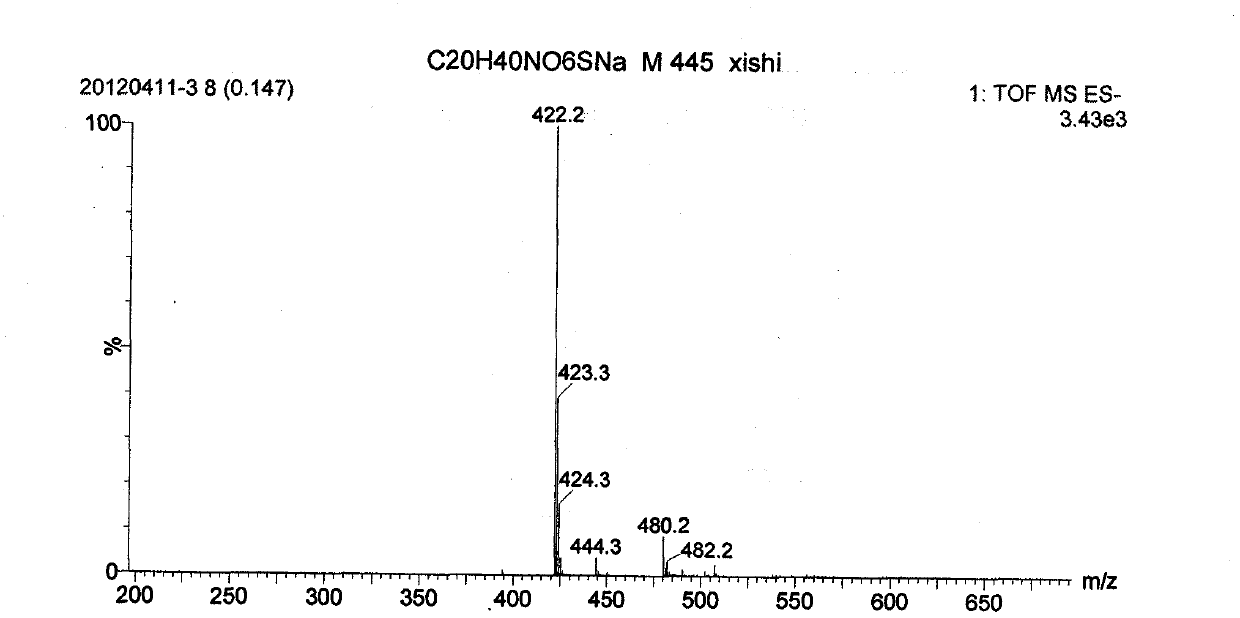

[0028] Preparation of palmitic acid diglycolamide sulfate

[0029] Add 9.00g of diglycolamine to a 500mL three-neck flask, dissolve it in 70ml of water, add 210mL of tetrahydrofuran (THF) at ice bath temperature (0-5°C), then add 16.12g of magnesium oxide, stir for about 30min, then slowly drop A tetrahydrofuran solution of palmitoyl chloride was added (25.83 g of palmitoyl chloride was dissolved in 70 mL of tetrahydrofuran). Control the dropping time to about 0.5h, and continue stirring for 2-2.5h. After the reaction, the reaction mixture was poured into a Buchner funnel for suction filtration to remove solid magnesium oxide and magnesium chloride, the filtrate was collected, the solvent was removed by rotary evaporation, and vacuum-dried at 50°C to obtain palmitic acid diglycolamide as white powder. figure 2 It is the infrared absorption spectrum of palmitic acid diglycolamide.

[0030] Add 12g of palmitic acid diglycolamide and 100ml of chloroform into a 250mL four-neck ...

Embodiment 3

[0032] Application of Coco Monoethanolamide Ethoxylate Sulfate.

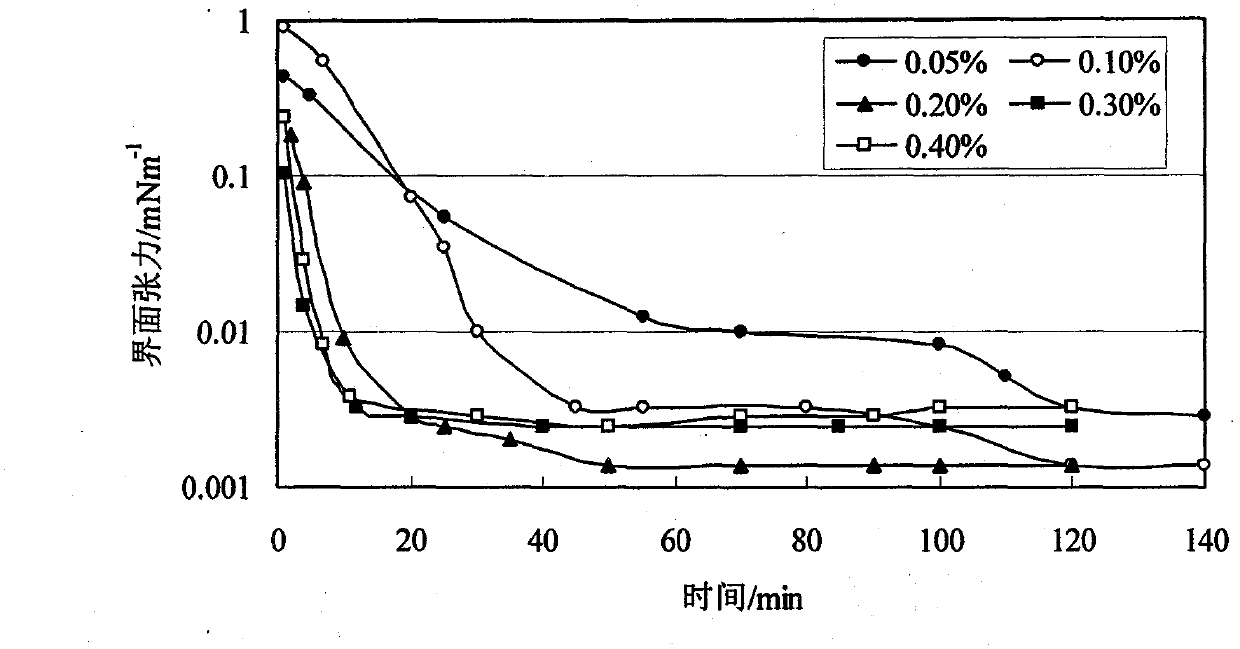

[0033] Cocoic acid monoethanolamide ethoxylate sulfate is compounded with other surfactants such as carboxybetaine amphoteric surfactants, and dissolved in the formation water of Daqing Oilfield (from the fourth oil production plant), wherein cocoic acid monoethanol The mole fraction of amide ethoxylate sulfate is 0.3, the total concentration (mass fraction) of surfactant is 0.05% to 0.4%, 1000mg / L polyacrylamide is dissolved in the formation water, without adding any alkali or alkaline salt , neutral inorganic salts, and co-surfactants, at 45°C (Daqing oil reservoir temperature), the equilibrium interfacial tension of Daqing crude oil (from No. 4 Oil Production Plant) / formation water can be reduced to 10 -3 On the order of mN / m, the result is as follows Figure 5 shown.

[0034] from Figure 5 It can be seen that when the total concentration of surfactants is ≥0.1%, the interfacial tension can be reduced to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com