Method of fementing shrimp heads to prepare active substances, chitin and organic acidity calcium

A technology for active substances and organic acid calcium, which is applied in the field of fermenting shrimp heads to prepare active substances, chitin and organic acid calcium, can solve the problems of high cost of enzyme preparations and limit the large-scale application of chitin, and achieves reduction of production costs and shrimp production. Strong fragrance and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

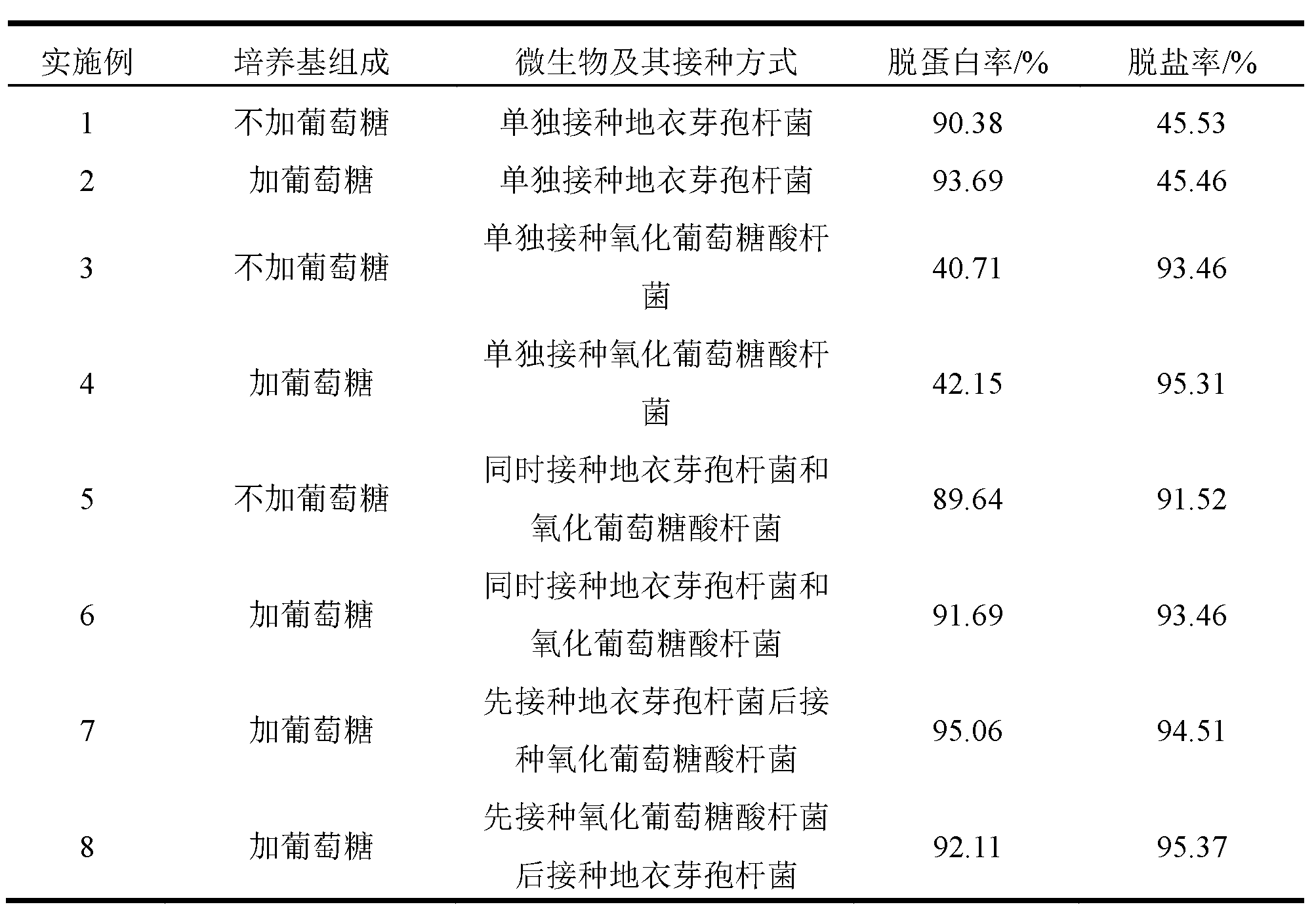

[0021] Take frozen prawn heads, weigh about 15g after thawing at room temperature, add a little water, homogenize through a high-shear homogenizer, and collect the homogenate. Add water 8 times the weight of the shrimp head to prepare the culture medium and sterilize at 121°C. Inoculate Bacillus licheniformis (B. licheniformis) that has been purified and refrigerated or vacuum freeze-dried into the seed medium (peptone 1%, yeast extract 0.5%, sodium chloride 1%, pH 7.2, the above concentrations are mass volume percentages ), placed in a 37°C incubator for 24 h with shaking, and then inoculated at 10% of the inoculation amount in the shrimp head culture medium for 48 h at 37°C, centrifuged at 4000 r / min for 5 min, and the fermentation broth and fermentation residue were collected respectively. The liquid part was spray-dried to obtain 1.09g of composite protein powder, and the precipitated part was dried to obtain 1.90g of chitin. The deproteinization rate and desalination rate...

Embodiment 2

[0023] Take the frozen prawn heads, weigh about 15g after thawing at room temperature, add a little water, homogenize through a high-shear homogenizer, and collect the homogenate. Add 10% glucose solution 8 times the weight of the shrimp head to prepare the medium and sterilize at 115°C. As for the added concentration of glucose, skilled artisans can adjust it according to the situation, and it is not limited to the description in this embodiment. Activate the purified Bacillus licheniformis stored in cold storage or vacuum freeze-drying. Other operations are the same as in Example 1. Finally, 1.20 g of protein and calcium gluconate composite powder and 1.69 g of chitin were obtained. The deproteinization rate and desalination rate in the determination process were 93.69% and 45.46%, respectively. It can be seen that the supplementation of additional carbon source (glucose) can improve the deproteinization rate of shrimp heads fermented by Bacillus licheniformis, and the des...

Embodiment 3

[0025] The pretreatment of the shrimp head is the same as in Example 1 (the aqueous glucose solution is not added to the slurry). Activate the purified Gluconobacter oxydans (G. oxydans) that has been refrigerated or vacuum freeze-dried. Other operations are the same as in Example 1. Finally, 1.53g of protein and calcium gluconate composite powder and 1.12g of chitin were obtained. The deproteinization rate and desalination rate in the determination process were 40.71% and 93.46%, respectively. The results show that Gluconobacter oxidans can grow with shrimp head as the only carbon and nitrogen source, can be directly fermented without sterilization, and has a high desalination rate, but the deproteinization rate is low, which is not as good as that of Bacillus licheniformis. / 2, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com