Method for producing manganese dioxide electrode of supercapacitor

A supercapacitor and manganese dioxide technology, applied in the field of electrochemistry, can solve the problem of difficult to obtain electrode materials with high power density and high energy density, the effective design of the surface and internal microstructure of difficult electrode materials, and the contact between electrode active materials and current collectors Defective and other problems, to achieve high specific volume characteristics, improve processing performance, reduce the effect of ohmic polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

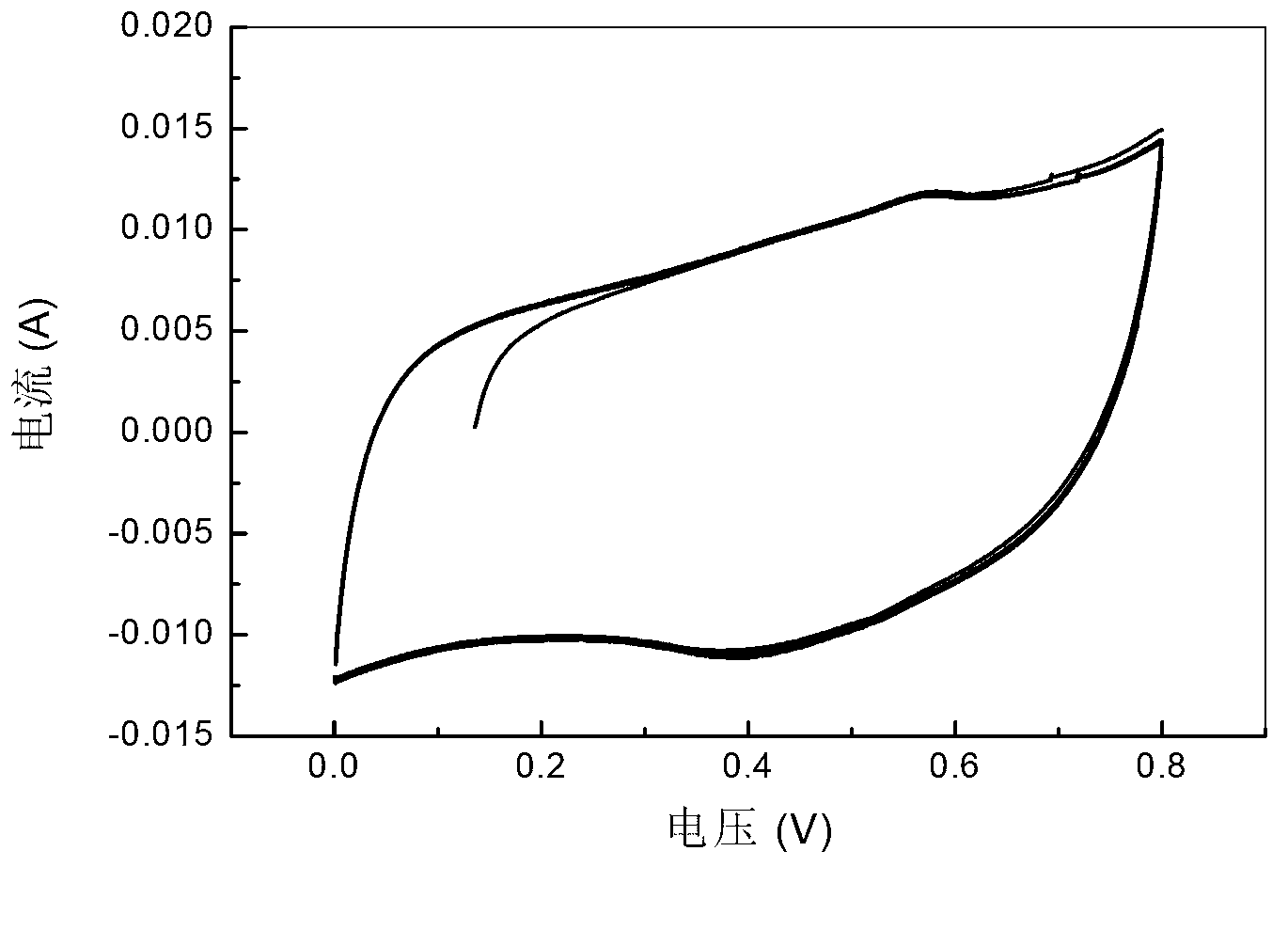

Examples

Embodiment 1

[0031] Configure MnSO separately 4 .H 2 O and NiSO 4 .7H 2 O aqueous solution, according to the molar ratio of nickel to disodium edetate is 1:1 to NiSO 4 Add disodium ethylenediamine tetraacetate into the solution and fully stir to form a uniform and transparent solution. Mix the prepared two solutions containing manganese salt and nickel salt, add ammonium sulfate and sodium lauryl sulfate to the mixed solution after mixing, and dissolve after adding water; the concentration of each component is: the concentration of manganese ions is 0.5mol / L, ammonium sulfate concentration is 1.2mol / L, nickel ion concentration is 0.025mol / L. Adjust the pH value of the solution to 5 with ammonia water, continue to stir for 60 minutes and set aside.

[0032] Cut the 304 stainless steel foil into an area of 4×1cm 2 The stainless steel belt is used as a current collector, and the current collector is ultrasonically washed with 10% sulfuric acid aqueous solution and acetone, and finally...

Embodiment 2

[0035] The operation process is the same as in Example 1, except that the concentration of manganese sulfate used is 0.8mol / L, and the soluble alloy component salt is CoSO 4 .7H 2 O, the complexing agent is sodium citrate, the molar ratio of cobalt to sodium citrate is 1:5, the concentration of ammonium sulfate is 0.9mol / L, and the concentration of cobalt ion is 0.016mol / L. Adjust the pH of the solution to 7 with ammonia. with NH 4 F0.1%, water 5% ethylene glycol solution is used as the electrolyte for anodic oxidation treatment, the voltage of the constant pressure oxidation tank is 80V, the measured cobalt content in the alloy coating is 11%, and the specific capacitance of the electrode active material is 381F / g .

Embodiment 3

[0037] The operation process is the same as in Example 1, except that the concentration of manganese sulfate used is 0.8mol / L, and the soluble alloy component salt is AgNO 3 , the complexing agent is NaCN, the molar ratio of silver to NaCN is 1:10, the Ag in the electroplating solution + The concentration is 0.02mol / L. Adjust the pH of the solution to 7 with ammonia. with NH 4 CL0.5%, water 5% ethylene glycol solution is the electrolyte for anodic oxidation treatment, the constant voltage oxidation cell voltage is 5V, with 0.1mA / cm 2 Charge and discharge at a constant current for 10 times, the measured silver content in the alloy coating is 4%, and the specific capacitance of the electrode active material is 437F / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com