Preparation method of microelement methionine hydroxy analogue chelate additive

A technology of methionine hydroxyl and trace elements is applied in the field of preparation of trace element methionine hydroxyl analog chelate additives, which can solve the problems of storage, transportation, inconvenient use, destruction of nutritional components, and difficulty in mixing evenly, so as to be beneficial to feed Processing and storage, growth promotion, good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

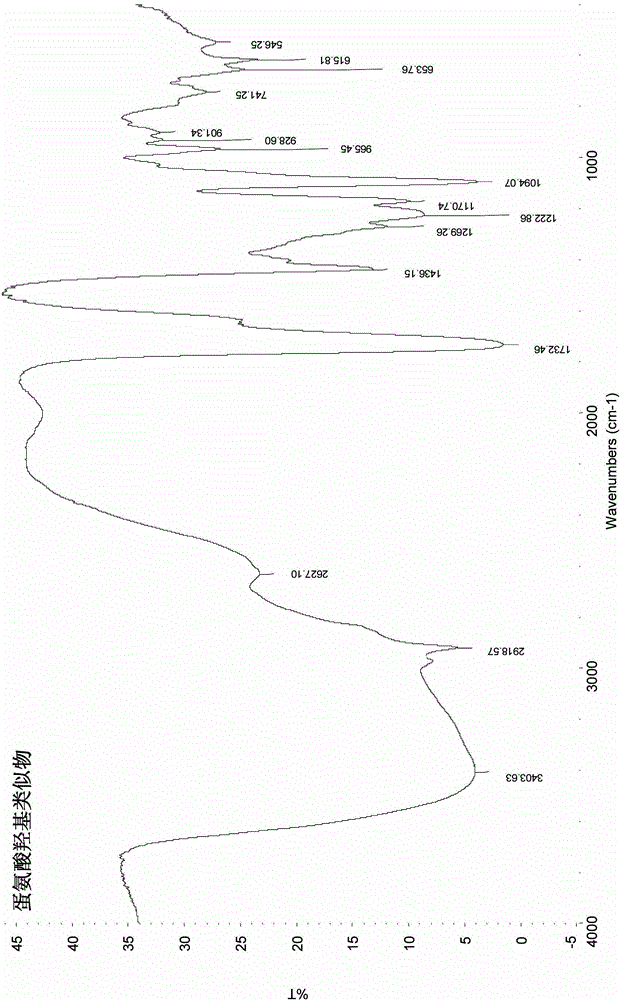

[0048] Embodiment 1: Preparation of methionine hydroxyl analog copper

[0049] Add 4.5t of water to 270kg of methionine hydroxy analogs, and stir to form an aqueous solution of methionine hydroxy analogs. Then add 10% potassium hydroxide solution prepared in advance, stir and react for 1 hour, and control the pH value to 5.4. Then add 170 kg of copper chloride dihydrate solid, stir and react for 3 hours, and control the pH at the end point to be 8.0. The reaction temperature in the reaction process is controlled within the range of 30-45°C. After the reaction was completed, it was centrifuged, washed with water for several times, then flashed and dried, and passed through a 40-mesh sieve to obtain the product methionine hydroxyl analog copper 318kg ((CH 3 SCH 2 CH 2 CH(OH)COO) 2 Cu) with a yield of 96% (based on the content of methionine hydroxyl analogs, the same below). The generated waste water enters the storage tank and stands still for a period of time, and the pH ...

Embodiment 2

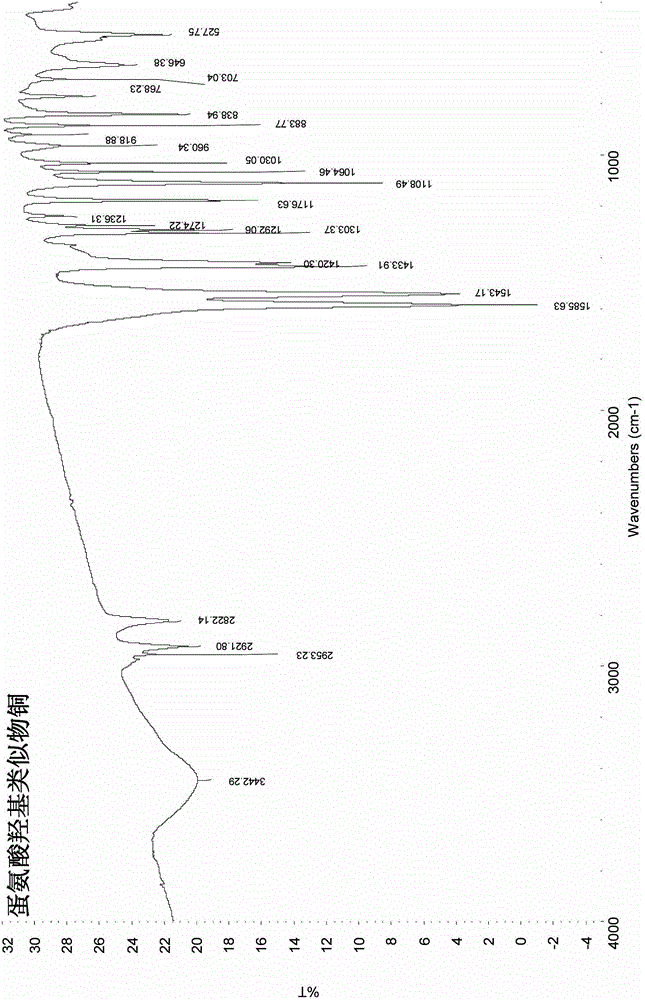

[0054] Embodiment 2: Preparation of methionine hydroxy analog ferrous

[0055] Add 0.8 t of 10% 1,2-propanediol-water solution to 375 kg of methionine hydroxy analog, and stir to prepare the methionine hydroxy analog 1,2-propanediol-water solution. Then add a pre-prepared sodium hydroxide solution with a mass fraction of 8%, stir and react for 0.2 h, and control the pH value to 4.0. Then add 200 kg of solid ferrous chloride tetrahydrate, stir and react for 0.5 h, and control the pH value at the end point to 5.0. The reaction temperature in the reaction process is controlled within the range of 30-45°C. After the reaction was completed, press filter, wash 2 times with 10% 1,2-propylene glycol-water solution, vacuum-dry to constant weight at 70°C, and cross a 60-mesh sieve to obtain the product methionine hydroxyl analog ferrous ((CH 3 SCH 2 CH 2 CH(OH)COO) 2 Fe·H 2 (0) 342kg, the productive rate is 89%. The waste water produced by the product methionine hydroxyl analog f...

Embodiment 3

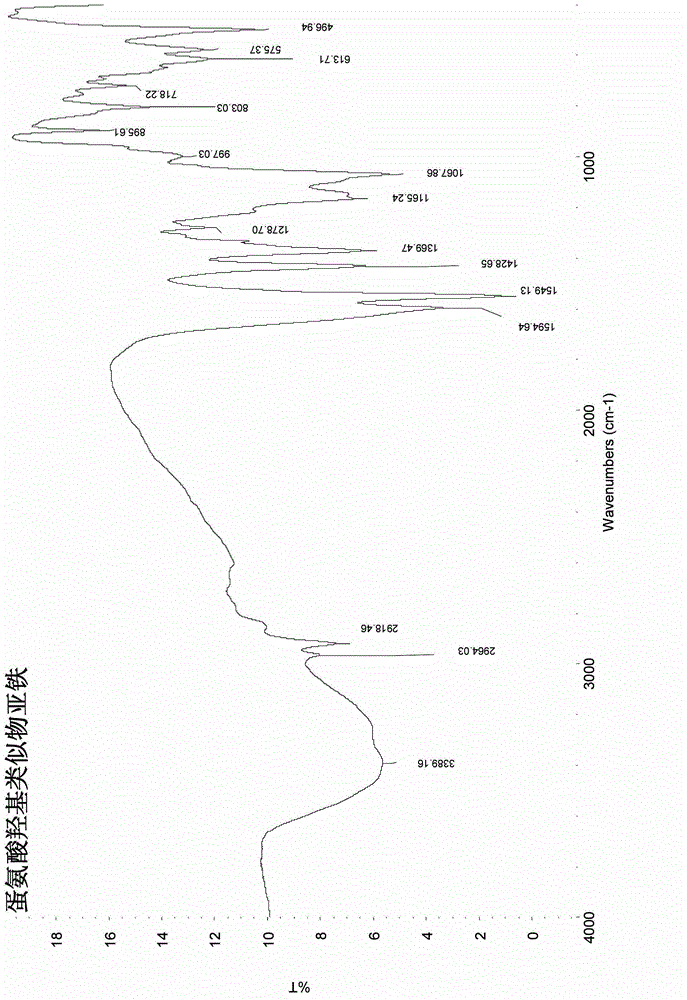

[0058] Embodiment 3: the preparation of methionine hydroxy analog zinc

[0059] Add 1Kg of sodium oxalate into 1 t of water, after the dissolution is complete, add 270kg of methionine hydroxy analogue, and stir to form a butyric acid-water solution of methionine hydroxy analogue. Then add the pre-prepared 1+3 ammonia solution (1+3 refers to the volume ratio of ammonia water to water is 1:3), stir and react for 0.5h, and control the pH value to 5.0. Then add 136 kg of anhydrous zinc chloride solid, stir and react for 3 hours, and control the end point pH value to 5.0. The reaction temperature during the reaction is controlled within the range of 20-60°C. After the reaction was completed, press filter, wash with water for 2 times, vacuum-dry to constant weight at 90°C, and pass through a 40-mesh sieve to obtain the product methionine hydroxyl analog zinc ((CH 3 SCH 2 CH 2 CH(OH)COO) 2 Zn·3H 2 (0) 297kg, the productive rate is 92%. The generated waste water enters the stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com