Preparation method for solar cell spectrum conversion polymeric membrane

A solar cell and spectrum conversion technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the light transmittance of the encapsulation film, the photoelectric conversion efficiency of solar cells, limitations, uneven distribution of spectrum conversion materials, etc. The effect of light transmittance and utilization of sunlight, long life and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

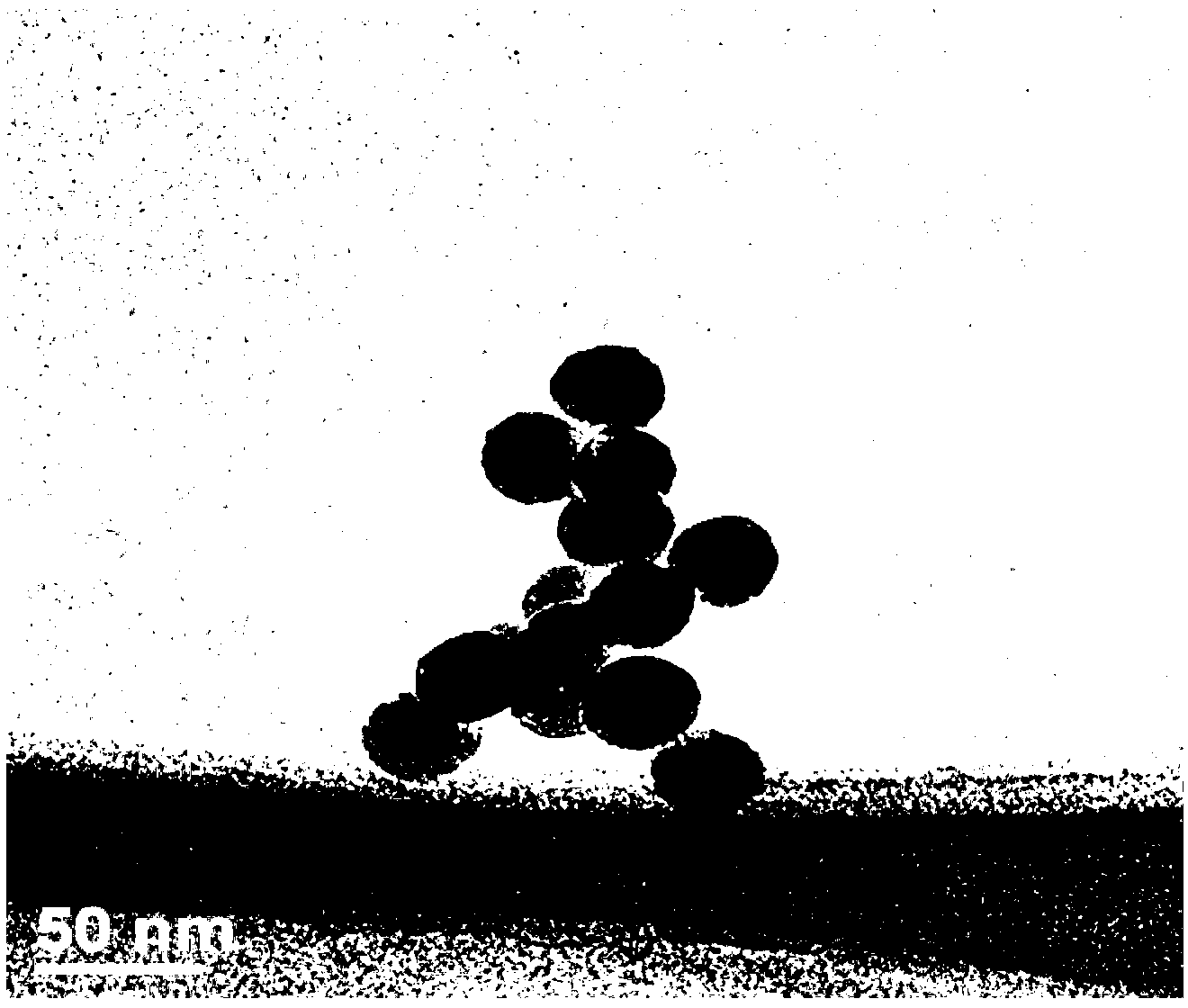

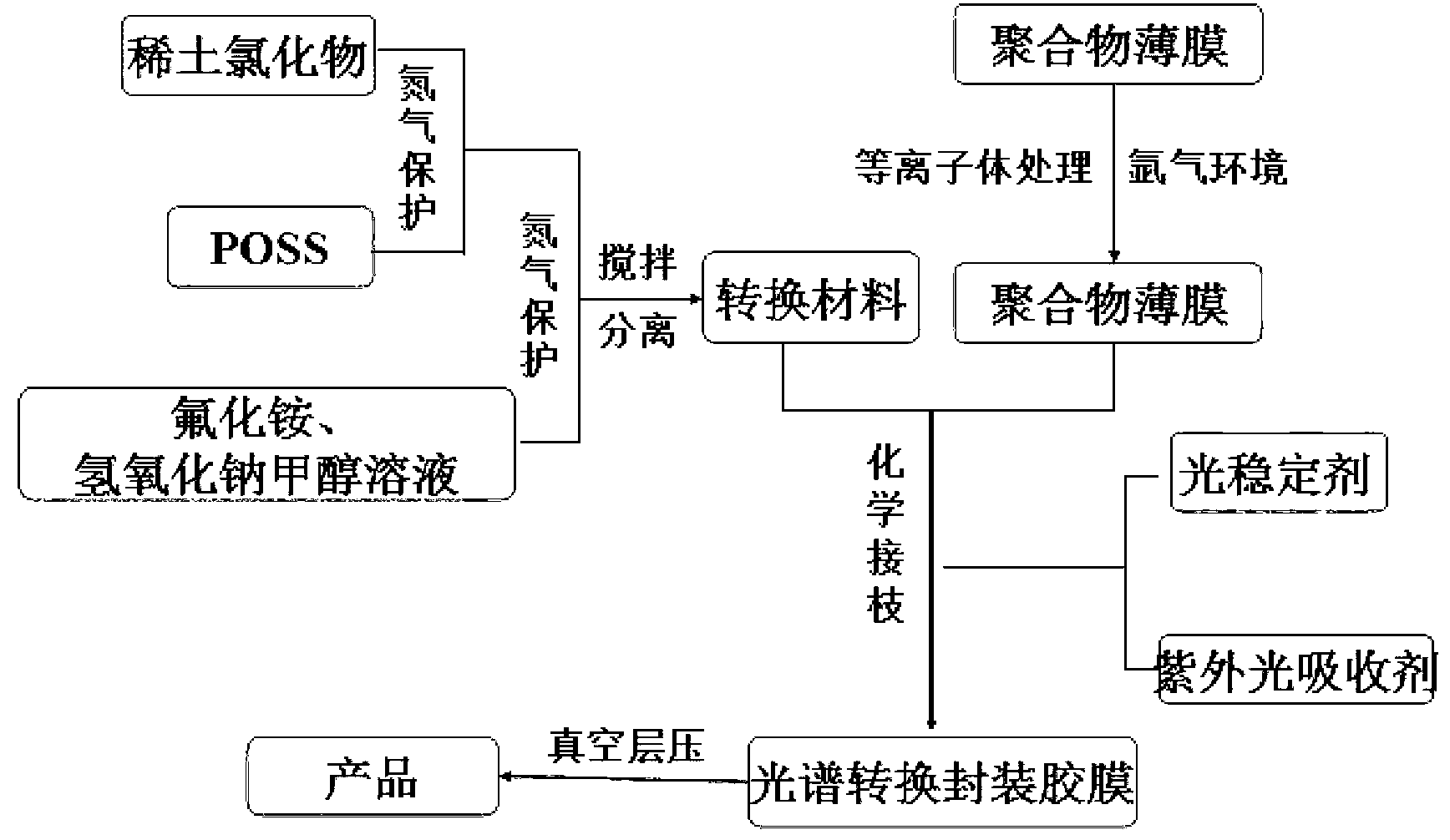

[0034] (1) Preparation of spectral conversion material: Take 15 g of silsesquioxane and add it to 30 mL of dichloromethane to prepare a silsesquioxane solution, then take 360 mg of rare earth chloride and add it to the above silsesquioxane solution , under the protection of nitrogen environment, under the condition of 130 ℃, stirred for 20 minutes and cooled to room temperature naturally to obtain solution A; take 120 mg of ammonium fluoride and 80 mg of sodium hydroxide mixed and dissolved in 10 mL of anhydrous methanol and add the above solution In A, after stirring at 40°C for 20 minutes, methanol volatilized to obtain solution B; under the protection of nitrogen environment, the temperature of solution B was raised to 280°C, kept for 40 minutes, then cooled to room temperature naturally, and the spectral conversion material was washed with ethanol The particles are separated out, and the spectrum conversion material I is obtained after repeated centrifugation, separation ...

Embodiment 2

[0040] (1) Preparation of Spectrum Conversion Material: Spectrum Conversion Material I was prepared in the same steps and conditions as in Example 1.

[0041] (2) Treatment of polymer film: plasma treatment of polyethylene composite film or polyvinyl fluoride composite film under the same conditions as in Example 1.

[0042] (3) Chemical grafting of spectral conversion material and treated polymer film: take 115 parts of plasma-treated polyethylene composite film or polyvinyl fluoride composite film according to raw material components and parts by weight, 10 parts of spectral conversion material I, light Stabilizer poly[1-(2-hydroxyethyl)-2,2,6,6-tetramethyl-4-hydroxypiperidine succinate] or sebacic acid bis-2,2,6,6-tetra 0.20 part of methyl piperidinol ester, 0.20 part of initiator azobisisobutyronitrile, ultraviolet light absorber 2-hydroxyl-4-n-octyloxybenzophenone or 2-(2H-benzotriazole-2 - 0.3 parts of -6-(dodecyl)-4-methylphenol, using the same steps and reaction condi...

Embodiment 3

[0045] (1) Preparation of Spectrum Conversion Material: Spectrum Conversion Material I was prepared in the same steps and conditions as in Example 1.

[0046] (2) Treatment of polymer film: plasma treatment of polyethylene composite film or polyvinyl fluoride composite film under the same conditions as in Example 1.

[0047] (3) Chemical grafting of spectral conversion material and treated polymer film: 130 parts of plasma-treated polyethylene composite film or polyvinyl fluoride composite film, 15 parts of spectral conversion material I, and light Stabilizer poly[1-(2-hydroxyethyl)-2,2,6,6-tetramethyl-4-hydroxypiperidine succinate] or sebacic acid bis-2,2,6,6-tetra 0.50 part of methyl piperidinol ester, 0.40 part of initiator azobisisobutyronitrile, ultraviolet light absorber 2-hydroxyl-4-n-octyloxybenzophenone or 2-(2H-benzotriazole-2 - 0.5 parts of -6-(dodecyl)-4-methylphenol, using the same steps and reaction conditions as in step (3) in Example 1 to prepare a spectral co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com