Lanthanide rare earth ion doped bismuth titanate monocrystal thin slice and preparation method thereof

An ion doping, lanthanide rare earth technology is applied in the field of lanthanide rare earth ion doped bismuth titanate single crystal flakes and its preparation, which can solve the problem that Bi salts are prone to hydrolysis side reactions, difficult to obtain bismuth titanate series materials, and contain bismuth titanate series materials. and other problems, to achieve the effect of large size, avoid the formation of impurity phase, and avoid hydrolysis reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

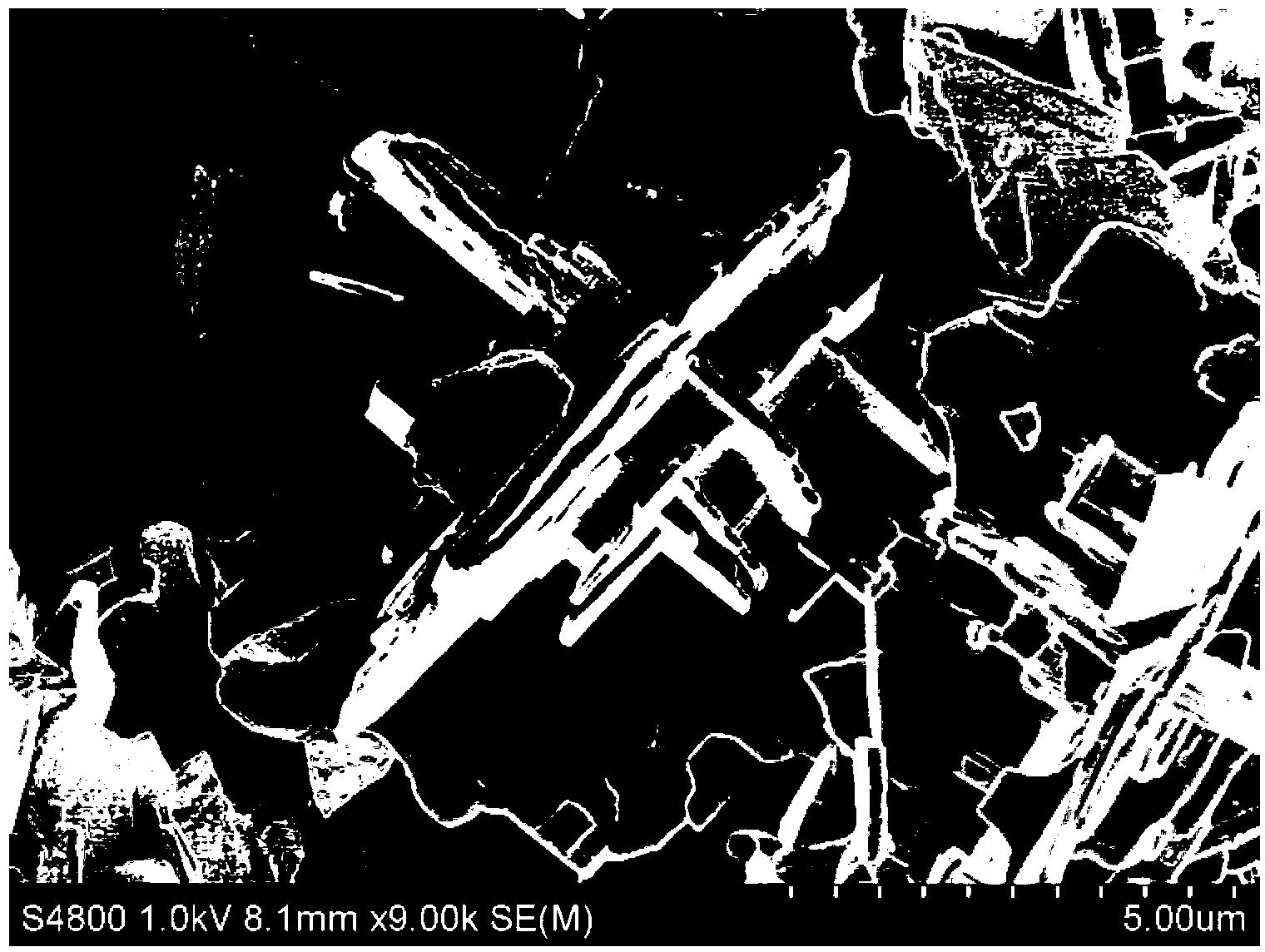

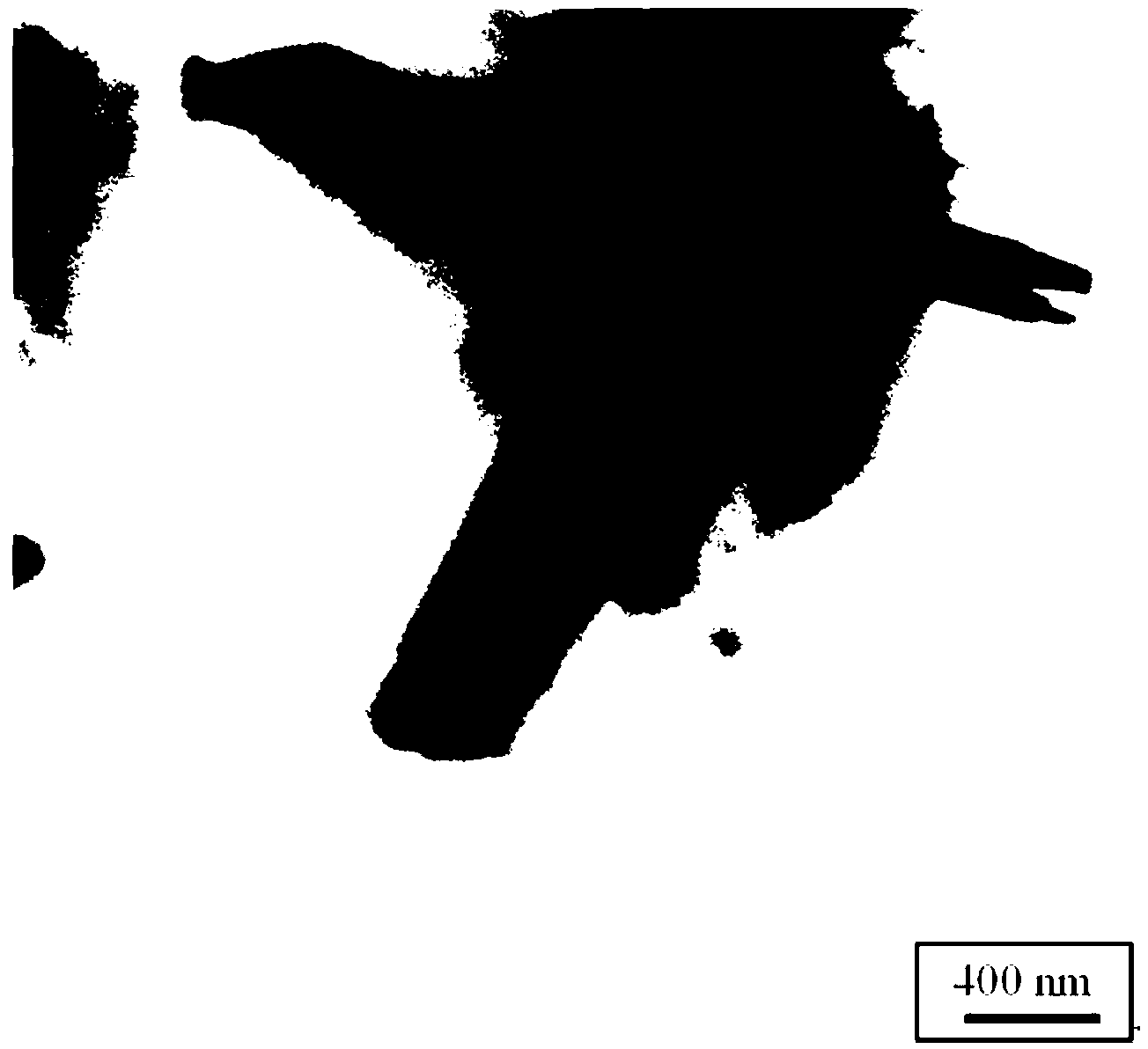

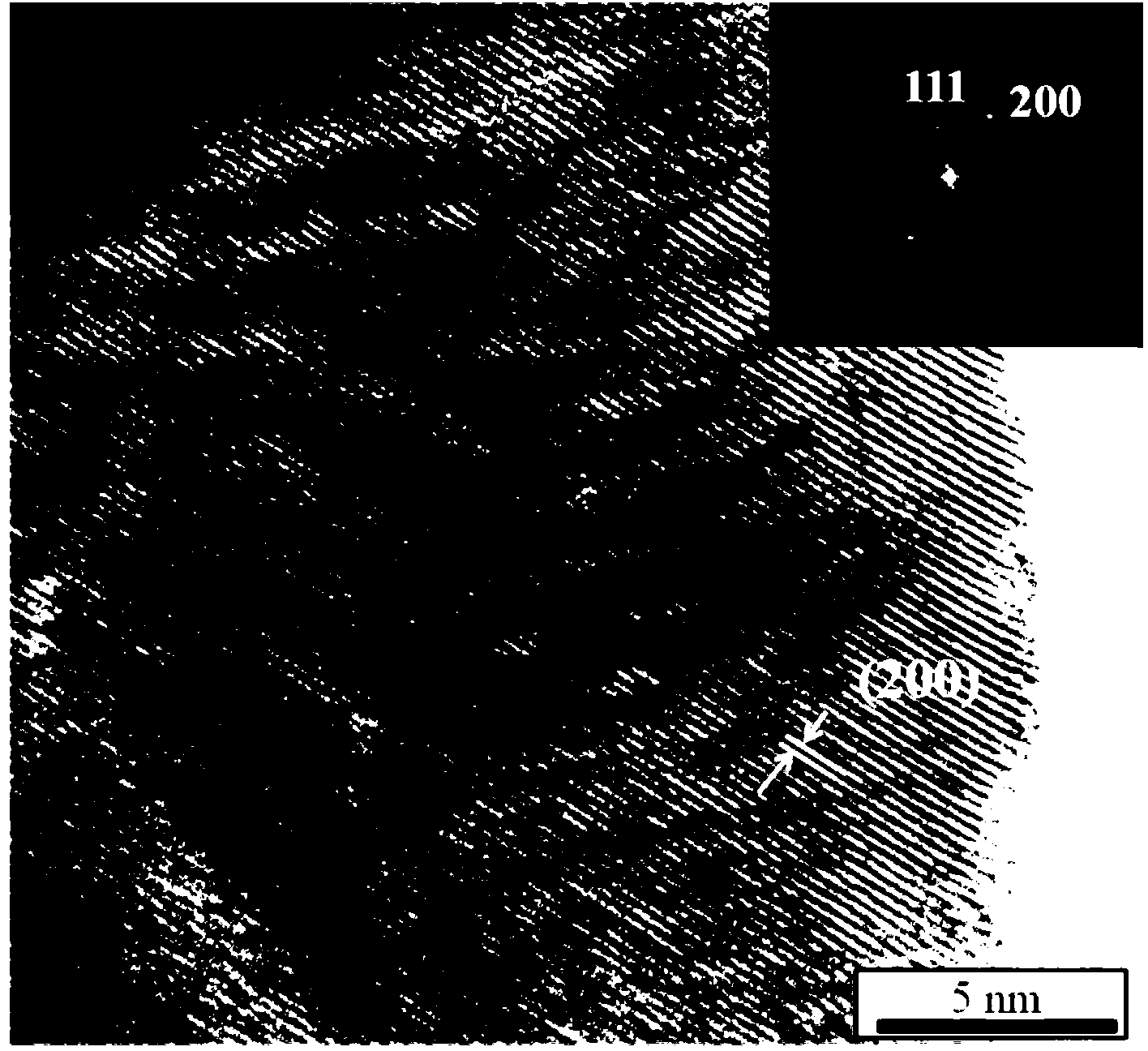

[0021] The first step: Weigh bismuth nitrate pentahydrate, neodymium nitrate and butyl titanate according to the molar ratio of 3.15:0.85:3, first dissolve bismuth nitrate pentahydrate and neodymium nitrate in ethylene glycol methyl ether, and then pour them into Add butyl titanate to prepare 16ml, 0.02mol / L Bi3.15Nd0.85Ti3O12 precursor solution;

[0022] Step 2: Dissolve 2mol / L sodium hydroxide in deionized water to prepare 4ml aqueous sodium hydroxide solution;

[0023] The third step: Add the solution in the second step to the Bi3.15Nd0.85Ti3O12 precursor solution in the first step to obtain a precipitate. After stirring the precipitate evenly, put it into the reactor and heat it to 160°C for 30 hours. The reaction is complete After cooling down to room temperature naturally, the bottom black precipitate was washed with distilled water and ethanol several times, and dried in a vacuum oven at 80°C for 12 hours to obtain Nd-doped bismuth titanate single crystal flakes.

Embodiment example 2

[0025] The first step: according to the molar ratio of 3.54:0.46:3, weigh bismuth nitrate pentahydrate, neodymium nitrate and butyl titanate, first dissolve bismuth nitrate pentahydrate and neodymium nitrate in ethylene glycol methyl ether, and then add them Add butyl titanate to prepare 15ml, 0.05mol / L Bi3.54Nd0.46Ti3O12 precursor solution;

[0026] Step 2: Dissolve 3mol / L sodium hydroxide in deionized water to prepare 5ml aqueous sodium hydroxide solution;

[0027] The third step: Add the solution in the second step to the solution in the first step to obtain a precipitate. After stirring the precipitate evenly, put it into a reaction kettle and heat it to 180°C for 25 hours. After the reaction is completed, cool it down to room temperature naturally. The bottom black precipitate was washed with distilled water and ethanol several times, and dried in a vacuum drying oven at 80°C for 12 hours to obtain neodymium-doped bismuth titanate single crystal flakes.

Embodiment example 3

[0029] The first step: according to the molar ratio of 3.7:0.3:3, weigh bismuth nitrate pentahydrate, neodymium nitrate and butyl titanate, first dissolve bismuth nitrate pentahydrate and neodymium nitrate in ethylene glycol methyl ether, and then add Add butyl titanate to it to prepare 14ml, 0.1mol / L Bi3.7Nd0.3Ti3O12 precursor solution;

[0030] Step 2: Dissolve 4mol / L sodium hydroxide in deionized water to prepare 6ml aqueous sodium hydroxide solution;

[0031] The third step: Add the solution in the second step to the solution in the first step to obtain a precipitate. After stirring the precipitate evenly, put it into a reaction kettle and heat it to 200°C for 20 hours. After the reaction is completed, cool it naturally to room temperature, and take The bottom black precipitate was washed with distilled water and ethanol several times, and dried in a vacuum drying oven at 80°C for 12 hours to obtain neodymium-doped bismuth titanate single crystal flakes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com