Hydroponic nutrient solution of water spinach

A hydroponic nutrient solution and water spinach technology, applied in fertilizer mixture, fertilization device, application, etc., can solve problems such as hindering plant growth, achieve the effects of improving disease resistance, scientific formula, and shortening the growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

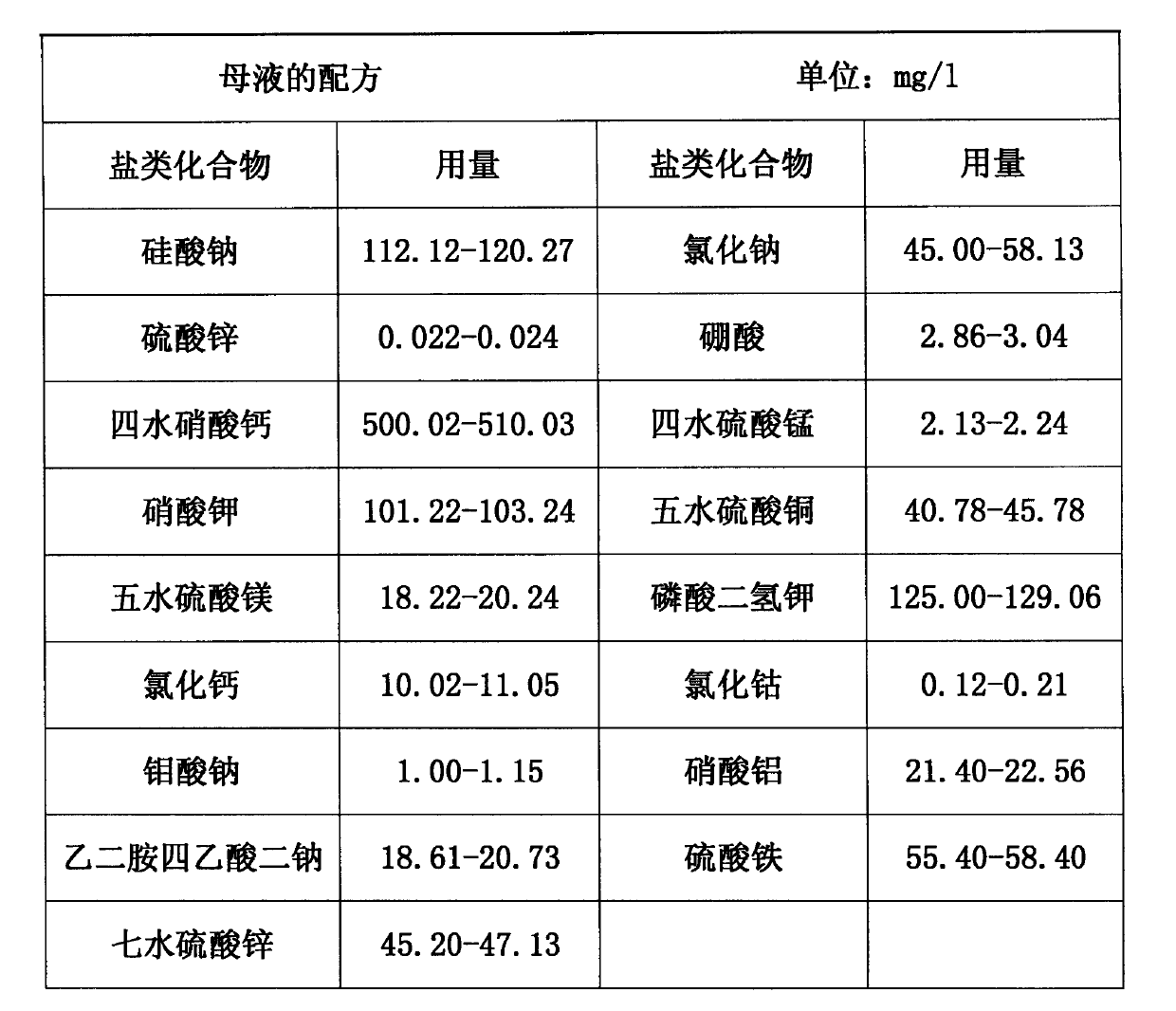

[0012] Each 1000ml of water spinach nutrient solution contains 160.20mg of sodium silicate, 0.023mg of zinc sulfate, 505.3mg of calcium nitrate tetrahydrate, 102.23mg of potassium nitrate, 19.23mg of magnesium sulfate pentahydrate, 10.54mg of calcium chloride, and sodium molybdate. 1.07mg, disodium edetate 19.67mg, zinc sulfate heptahydrate 46.17mg, sodium chloride 51.56mg, boric acid 2.94mg, manganese sulfate tetrahydrate 2.14mg, copper sulfate pentahydrate 43.28mg, potassium dihydrogen phosphate 127.03mg , cobalt chloride 0.017mg, aluminum nitrate 21.98mg, iron sulfate 56.9mg.

Embodiment 2

[0014] Each 1000ml of water spinach nutrient solution contains 112.12mg of sodium silicate, 0.022mg of zinc sulfate, 500.02mg of calcium nitrate tetrahydrate, 101.22mg of potassium nitrate, 18.22mg of magnesium sulfate pentahydrate, 10.02mg of calcium chloride, and sodium molybdate. 1.00mg, disodium edetate 18.61mg, zinc sulfate heptahydrate 45.20mg, sodium chloride 45.00mg, boric acid 2.86mg, manganese sulfate tetrahydrate 2.13mg, copper sulfate pentahydrate 40.78mg, potassium dihydrogen phosphate 125.00mg , cobalt chloride 0.12mg, aluminum nitrate 21.40mg, iron sulfate 55.40mg.

Embodiment 3

[0016] Each 1000ml of the water spinach nutrient solution contains 120.27mg of sodium silicate, 0.024mg of zinc sulfate, 510.03mg of calcium nitrate tetrahydrate, 103.24mg of potassium nitrate, 20.24mg of magnesium sulfate pentahydrate, 11.05mg of calcium chloride, and sodium molybdate. 1.15mg, disodium edetate 20.73mg, zinc sulfate heptahydrate 47.13mg, sodium chloride 58.13mg, boric acid 3.04mg, manganese sulfate tetrahydrate 2.24mg, copper sulfate pentahydrate 45.78mg, potassium dihydrogen phosphate 129.06mg , cobalt chloride 0.21mg, aluminum nitrate 22.56mg, iron sulfate 58.40mg.

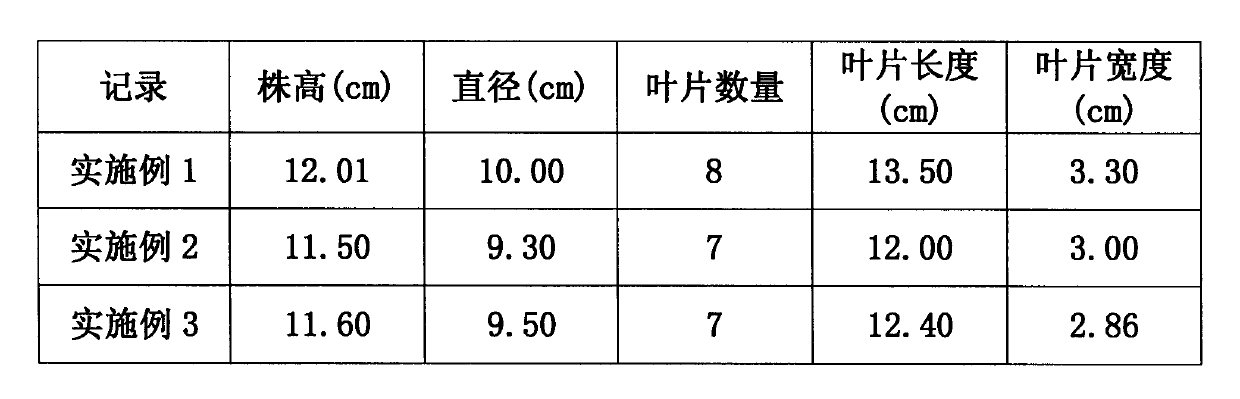

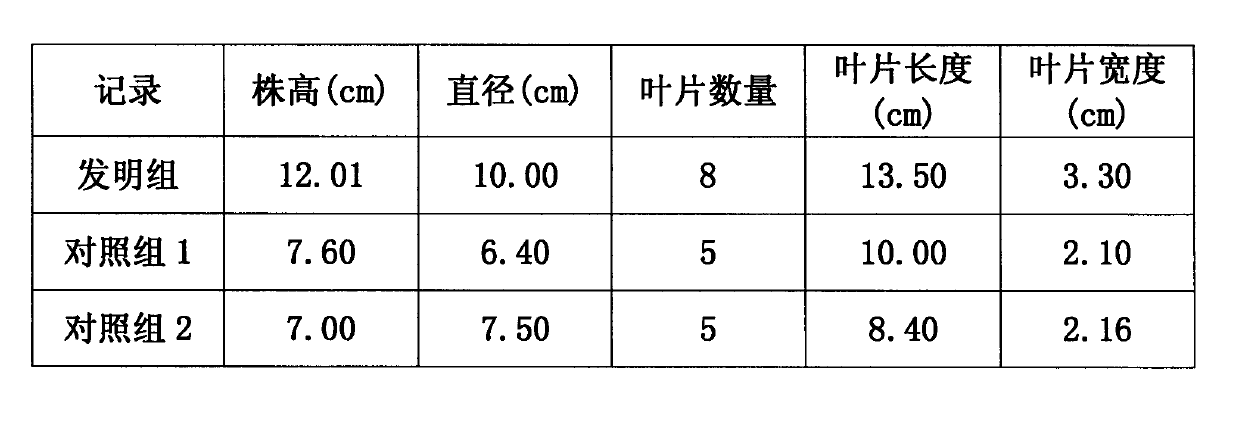

[0017] Described experimental group (embodiment 1, embodiment 2, embodiment 3) selects the same water spinach plant of shape and size, they are placed in identical and suitable environment and cultivate one month, record the growth situation of three groups of experimental plants after one month ( figure 2 ).

[0018] The specific use method of the water spinach hydroponic nutrient solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com