Polymer solar cell

A technology of solar cells and polymers, applied in the field of solar cells, can solve the problems of low energy conversion efficiency and low conductivity of polymer solar cells, and achieve the effects of facilitating electron transmission and collection, increasing short-circuit current, and increasing conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation process of the inverted structure polymer solar cell comprises the following steps:

[0032] forming a cathode layer 2 on the substrate 1;

[0033] A composite of zinc oxide-phosphate polyfluorene is used on the above-mentioned cathode layer 2 to form a cathode interface layer 3;

[0034] Prepare a blend of conjugated polymers and fullerene derivatives on the cathode interface layer 3 to form a photosensitive layer 4;

[0035] On the photosensitive layer 4, an anode interface layer 5 and an anode layer 6 are sequentially evaporated to obtain a polymer solar cell.

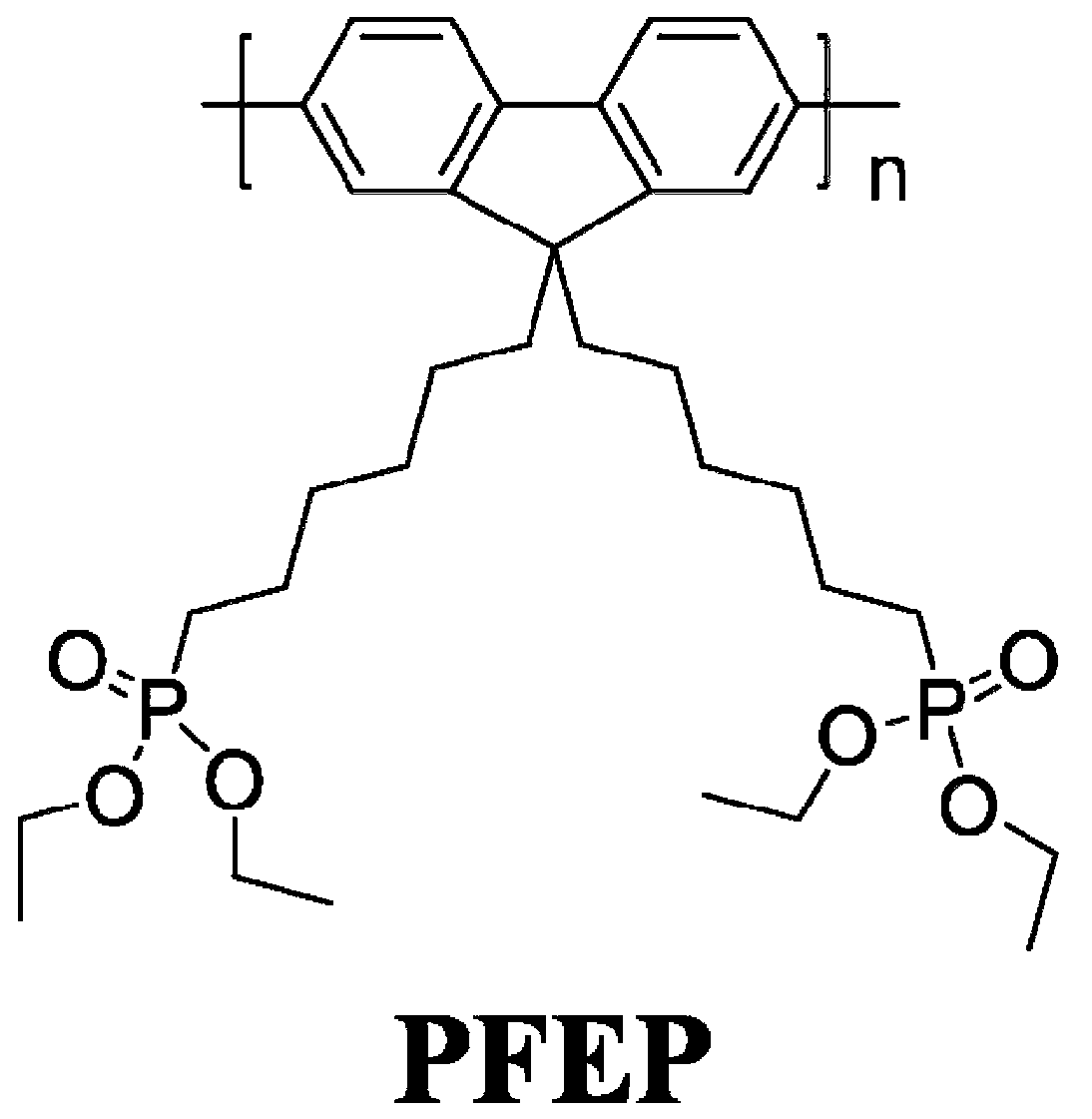

[0036] The substrate 1 is a rigid or flexible substrate, the cathode layer 2 is indium tin oxide (ITO), the cathode interface layer 3 is a zinc oxide-phosphoester polyfluorene hybrid material, and the ZnO-PFEP composite cathode interface layer 3 The mass ratio of ZnO to PFEP ranges from 100:1 to 1:100, most preferably 6:1.

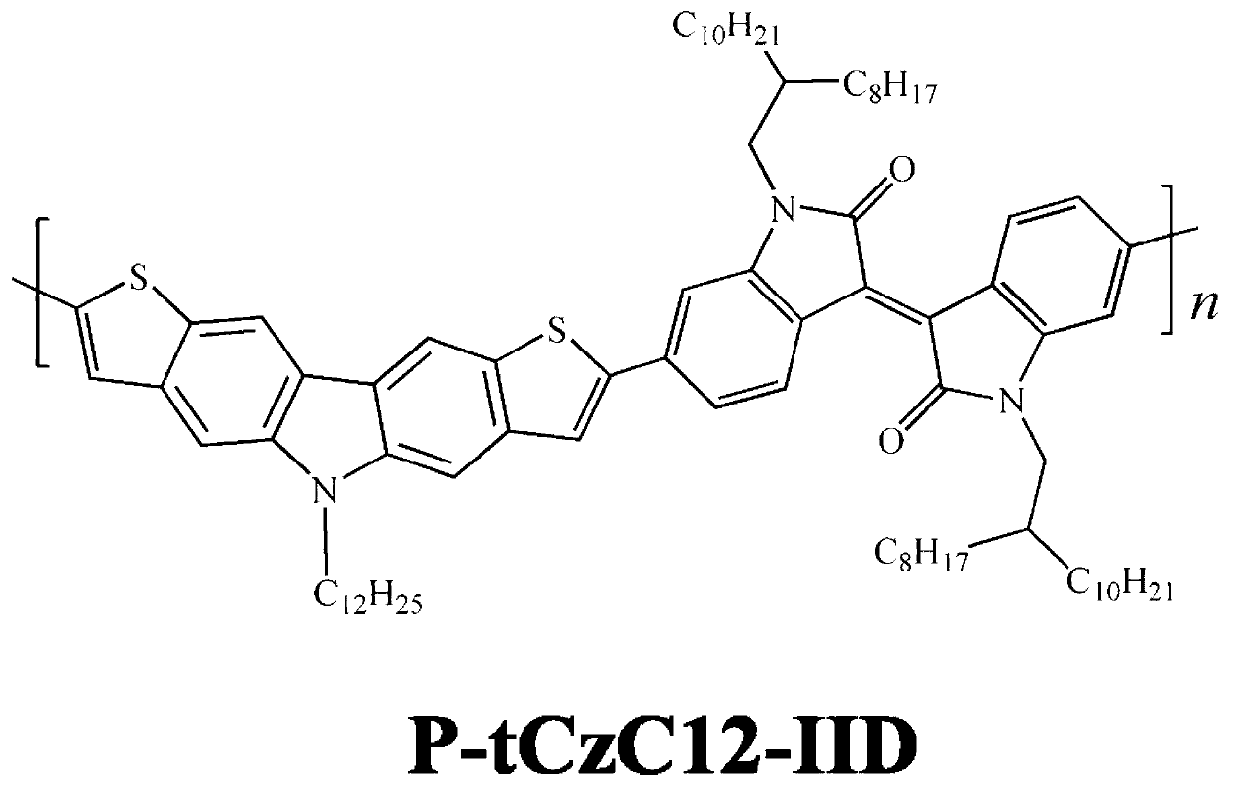

[0037] The photosensitive layer 4 is a blend of conjugated polymer...

Embodiment 1

[0052] (1) The etched glass substrate 1 with thin strip-shaped ITO cathode layer 2 is cleaned and dried, then placed on the bracket of the coating machine, and the stirred ZnO-PFEP mixed solution is passed through 0.45 micron The filter head is evenly coated on the top of the cathode layer ITO, and the coating film is rotated at a speed of 300 rpm to obtain a cathode interface layer 3 with a thickness of 100 nanometers; the ZnO-PFEP mixed solution is obtained by adding 30 mg of zinc oxide ( ZnO) and 5 mg phosphate polyfluorene (PFEP) were dissolved in 1 ml of n-butanol solvent, and the mixed solution obtained after magnetic stirring for 12 hours;

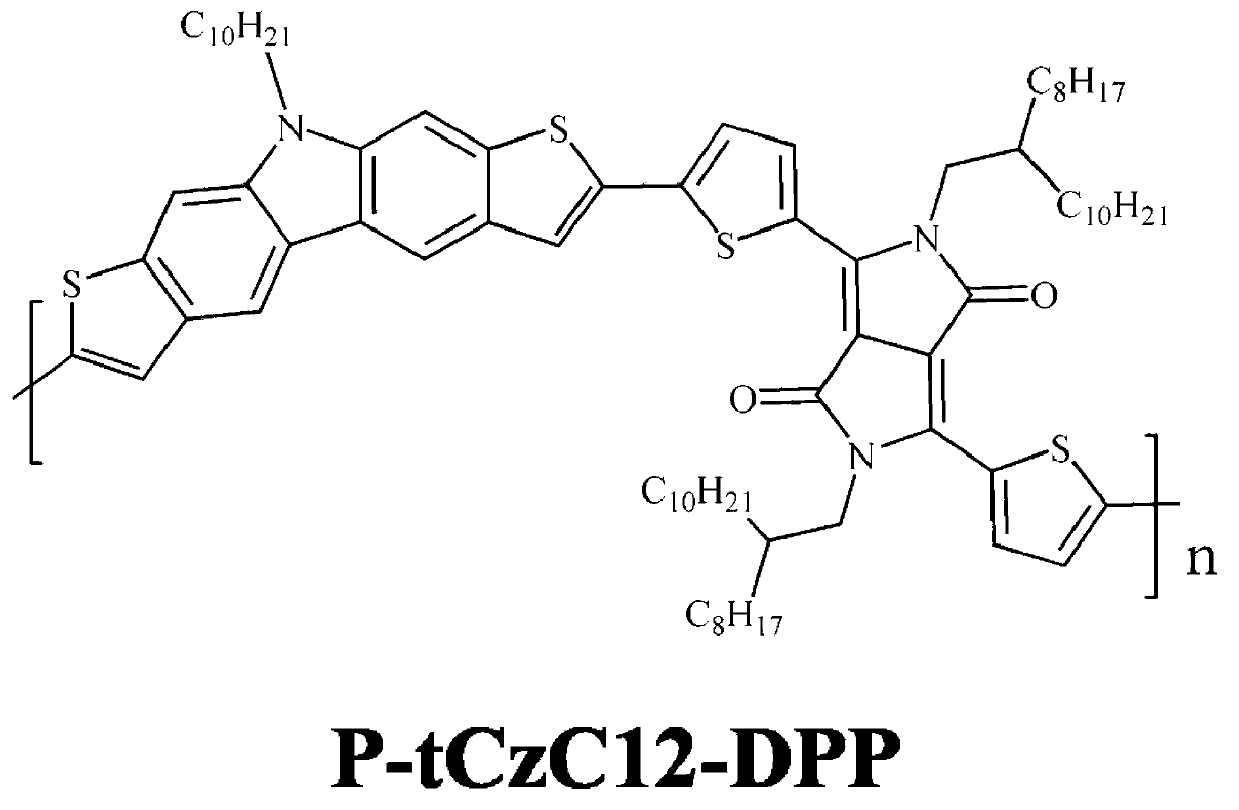

[0053] (2) Spin coating The substrate coated with the cathode interface layer 3 is placed on the carriage of the coating machine, and the stirred poly[2,8-N-dodecyldithieno[3,2 -b;6,7-b]carbazole-alt-3,6-bis(thiophen-2-yl)-2,5-bis(2-octyldodecyl)pyrrolo[3,4-c ]pyrrole-1,4-dione](P-tCzC12-DPP) with PC 70 The mixed solution of BM is...

Embodiment 2

[0058] (1) The etched glass substrate 1 with thin strip-shaped ITO cathode layer 2 is cleaned and dried, then placed on the bracket of the coating machine, and the stirred ZnO-PFEP mixed solution is passed through 0.45 micron The filter head is evenly coated on the top of the cathode layer ITO, and the coating film is rotated at a speed of 7000 rpm to obtain a cathode interface layer 3 with a thickness of 1 nanometer; the ZnO-PFEP mixed solution is obtained by adding 100 mg of zinc oxide ( ZnO) and 1 mg of phosphate polyfluorene (PFEP) were dissolved in 100 ml of n-butanol solvent, and the mixed solution obtained after magnetic stirring for 12 hours;

[0059] (2) Spin coating The substrate 1 coated with the cathode interface layer 3 is placed on the carriage of the coating machine, and the stirred P-tCzC12-DPP and PC 70 The mixed solution of BM is evenly coated on the above-mentioned ZnO / PFEP cathode interface layer 3, and the coating film is rotated at a speed of 3000 rpm to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com