An electrostatically spun chitosan nano-fiber film for adsorption of heavy metal ions and a preparation method thereof

A technology of chitosan nanometer and adsorption of heavy metals, which is applied in the direction of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc. High cost and other issues, to achieve the effect of more internal pores, increase the contact area, and shorten the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

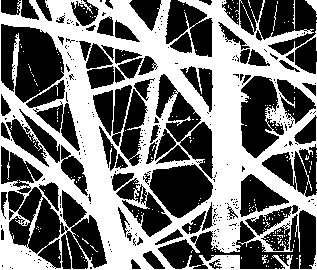

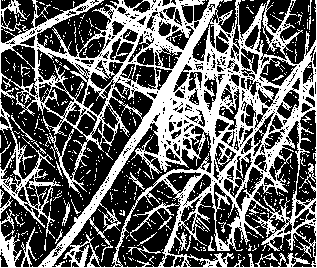

Image

Examples

Embodiment 1

[0018] (1) Select the shell polycan with LG dehydrate of 70%and a molecular weight of 200,000, dissolved in 19g triathoacetic acid, ultrasonic treatment for 1h, and obtain a shell polycan solution with a mass of 5%.

[0019] (2) Add the above spinning liquid to the static spinning device, use electrostatic spinning legal system to prepare the shell polyanan nanofiber membrane, and the process of static spinning is: voltage 15kV, spinning distance 10cm, spinning solution into inQuantity 0.5ml / h;

[0020] (3) Immersed the shell polytanan nanofiber membrane prepared by the static spinning legal system in Nahco of 1mol / L 3 After soaking for 24h in the solution, a neutral and chitosan nano -fiber membrane is obtained.

[0021] The average diameter of the obtained steps (2) the obtained shell glycogen nanofibilities is 88nm, and the pore rate is 69%.

[0022] Step (3) The obtained shell polytal nanofibiliated membrane to CU 2+ The adsorption amount is 328mg / g, for PB 2+ The adsorption a...

Embodiment 2

[0025] (1) Select a chitosan with a LG dehydrate of 75%and a molecular weight of 220,000. It is dissolved in 24g of triathide, and the ultrasonic treatment is 1.5h to obtain a shell poly glycogen solution with a mass ratio of 4%;

[0026] (2) Add the above spinning fluid into the static spinning device, use electrostatic spinning legal system to prepare the shell polynan nanofiber membrane, and the process of static spinning is: 20kV of the voltage, 15cm spinning distance, spinning solution into it1ml / h;

[0027] (3) Immersed the shell polytanan nanofiber membrane prepared by the static spinning legal system in Nahco of 1mol / L 3 After soaking for 24h in the solution, a neutral and chitosan nano -fiber membrane is obtained.

[0028] The average diameter of the obtained steps (2) obtained by the obtained shell polytanan nanofibilities is 142nm, and the pore rate is 52%.

[0029] Step (3) The obtained shell polytal nanofibiliated membrane to CU 2+ The adsorption amount is 183mg / g, fo...

Embodiment 3

[0032] (1) Select the shell poly glycogen with an LG acetylness of 80%and a molecular weight of 250,000. It is dissolved in 32.3g of trifluoroetic acid.

[0033] (2) Add the above spinning fluid into the static spinning device, use electrostatic spinning legal system to prepare the shell polyanan nanofiber membrane, and the process of static spinning is: voltage 25kV, spinning distance 15cm, spinning liquid into it intoQuantity 1.5ml / h;

[0034] (3) Immersed the shell polytanan nanofiber membrane prepared by the static spinning legal system in Nahco of 1mol / L 3 After soaking for 24h in the solution, a neutral and chitosan nano -fiber membrane is obtained.

[0035] The average diameter of the obtained steps (2) the obtained shell polytanan nanofibilities is 108nm, and the pore rate is 64%.

[0036] Step (3) The obtained shell polytal nanofibiliated membrane to CU 2+ The adsorption amount is 209mg / g, for PB 2+ The adsorption amount is 68mg / g.

[0037] Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com