RAFT (Reversible Addition-Fragmentation chain Transfer) reaction reagent based on low molecular weight carbon dioxide copolymer and preparation method of RAFT reaction reagent

A carbon dioxide, low molecular weight technology, applied in the field of RAFT reaction reagent and its preparation, can solve problems such as preparation methods that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

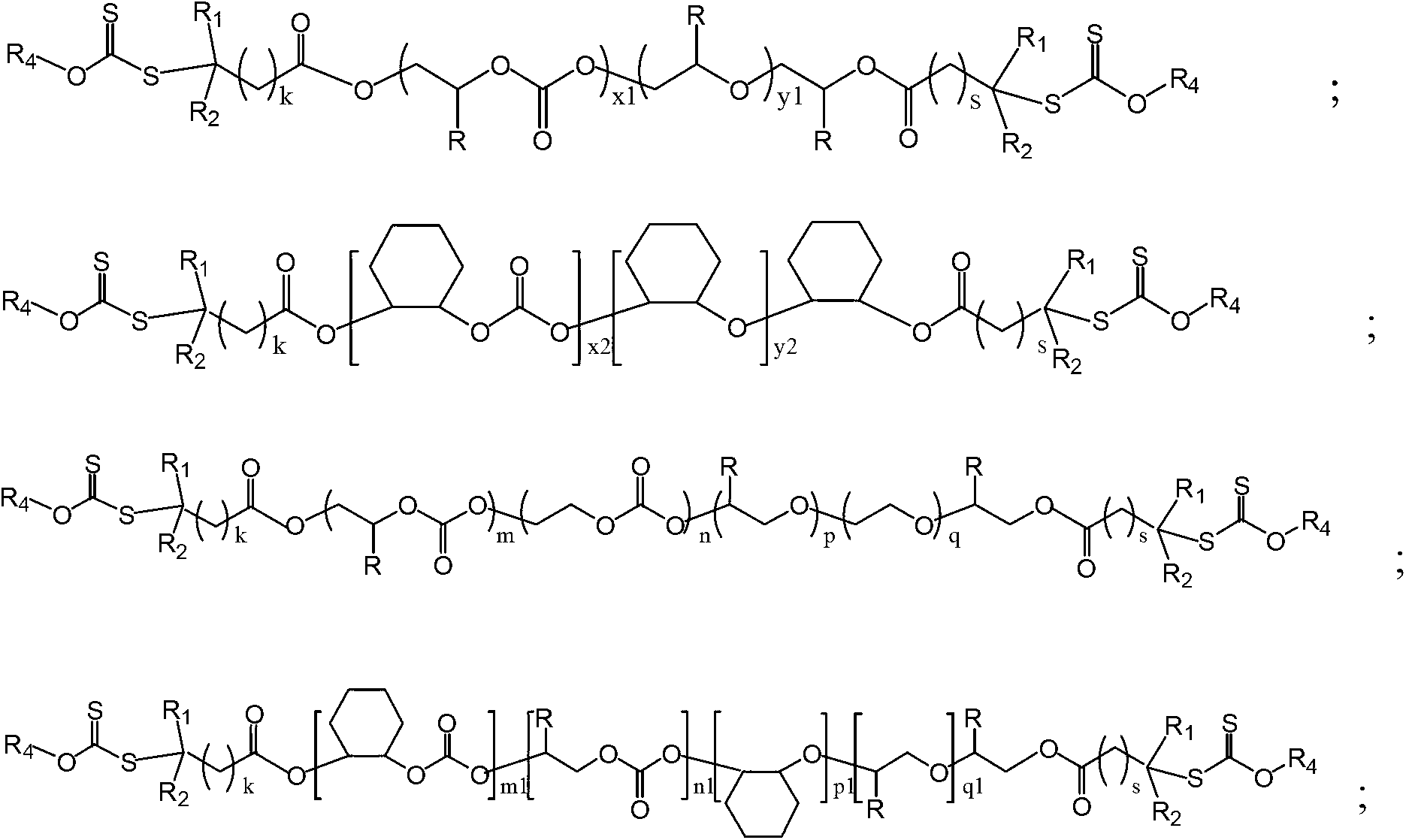

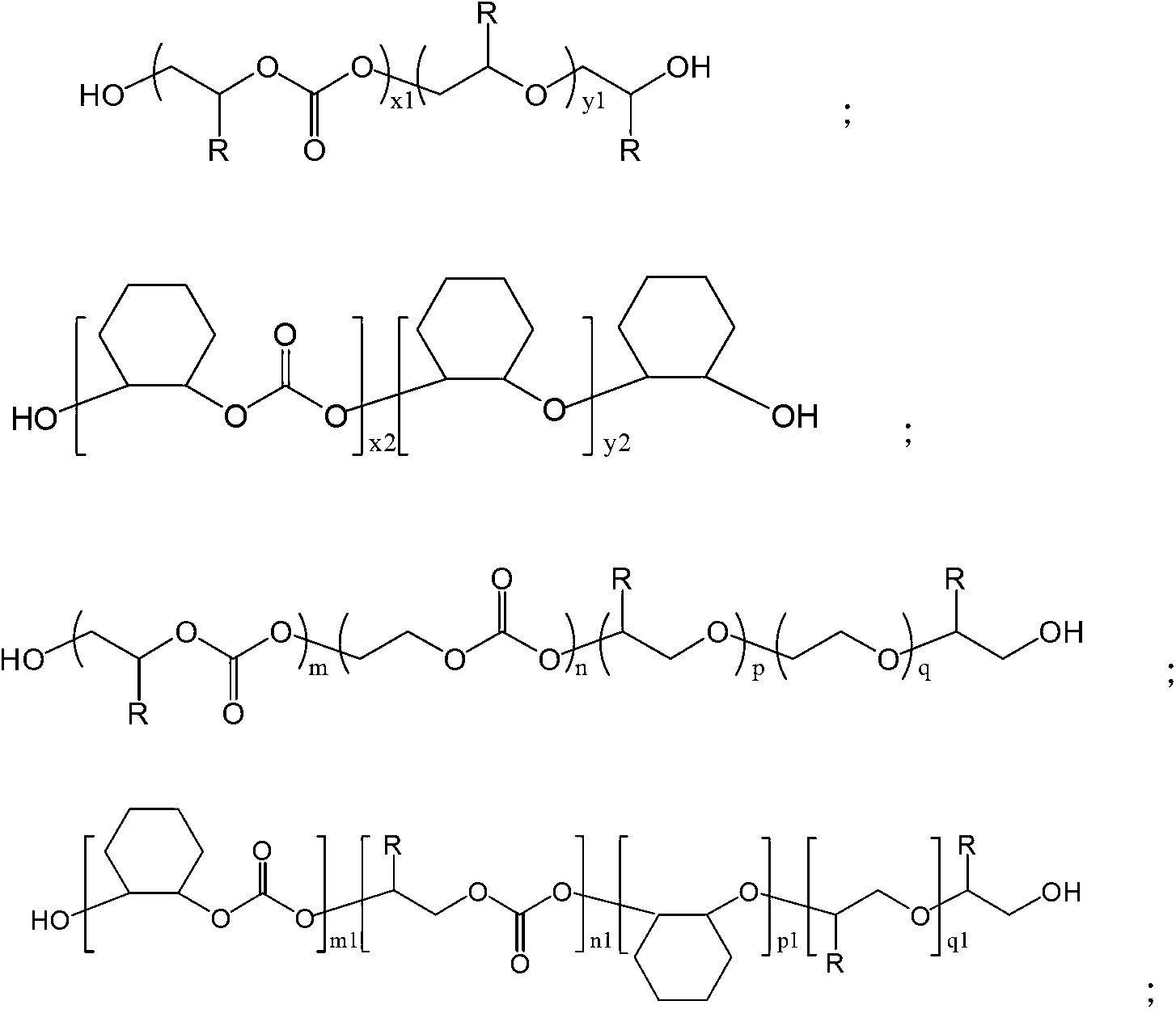

[0067] The present invention also relates to a preparation method of RAFT reaction reagent based on low molecular weight carbon dioxide copolymer, comprising the steps of:

[0068] The first step reaction: the low molecular weight carbon dioxide copolymer HO-(CO 2 -based polymer)-OH is dissolved in anhydrous aromatic hydrocarbon solvent under stirring to form a 3-50wt% solution, and after bubbling with nitrogen gas for 10-60 minutes, heat up to 90-210°C and evaporate the total solvent 10-40wt% aromatic hydrocarbons;

[0069] Continue to lower the temperature to 0°C under the condition of blowing nitrogen and add organic amine or pyridine compound as an acid-binding agent, or introduce the acidic tail gas of hydrogen halide generated by the reaction into the lye absorption device;

[0070] Then, add haloacyl halides to the above solution, keep stirring after the addition of haloacyl halides to complete the reaction, let stand, filter to remove solid insolubles, and distill and...

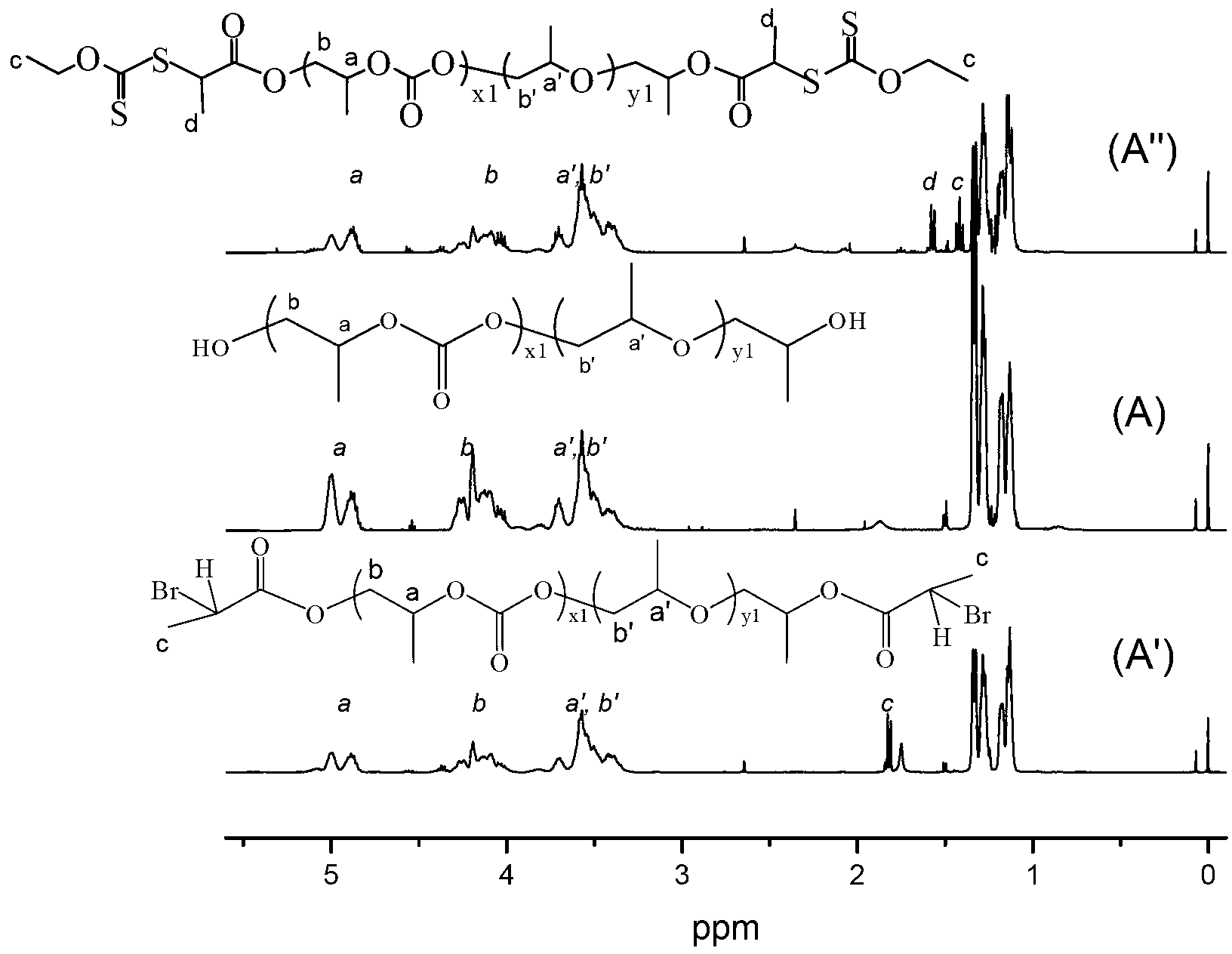

Embodiment 1

[0100] Embodiment 1: the first step reaction: 10mmol low molecular weight carbon dioxide copolymer (Mn=3000) is dissolved in 300ml anhydrous toluene / xylene (V 甲苯 / V 二甲苯 =50 / 50) in the mixed solvent, after nitrogen gas bubbling for 20 minutes, the temperature was raised to 130-140° C., after 50 ml of solvent was evaporated, the temperature was lowered to 0° C. and 26 mmol of pyridine was added as an acid-binding agent; Then add 26mmol of 2-chloro-2-methylpropionyl bromide dropwise, keep stirring after the addition of 2-chloro-2-methylpropionyl bromide to complete the reaction, let stand, filter to remove solid insolubles, and The solvent in the filtrate is recovered by distillation to obtain a low molecular weight carbon dioxide copolymer crude product containing halogen atom chlorine at the end. The crude product was dissolved in 200ml of dichloromethane solvent, then washed twice with 60ml of saturated ammonium chloride solution, 60ml of saturated sodium bicarbonate solution...

Embodiment 2

[0102] Example 2: The first step reaction: 19.2mmol of low molecular weight carbon dioxide copolymer (Mn=2500) was dissolved in 440ml of anhydrous toluene solvent under stirring, after bubbling with nitrogen for 30 minutes, the temperature was raised to 130-140°C, evaporated After removing 50ml of toluene, lower the temperature to 0°C under the condition of blowing nitrogen and add 45mmol of triethylamine as an acid-binding agent; then add 45mmol of 2-bromopropionyl bromide dropwise, and after the addition of 2-bromopropionyl bromide is completed, Keep stirring to make the reaction complete, let stand, filter to remove solid insolubles, and recover the solvent in the filtrate by distillation to obtain a low molecular weight carbon dioxide copolymer crude product containing halogen atom bromine at the end. The crude product was dissolved in 350ml of dichloromethane solvent, then washed twice with 50ml of saturated ammonium chloride solution, saturated sodium bicarbonate solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com