Preparation method for ferulic acid

A technology of ferulic acid and fiber raw materials, applied in the preparation of organic compounds, chemical instruments and methods, preparation of oxygen-containing compounds, etc., to achieve the effects of mild conditions, reduced cost and pollution, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

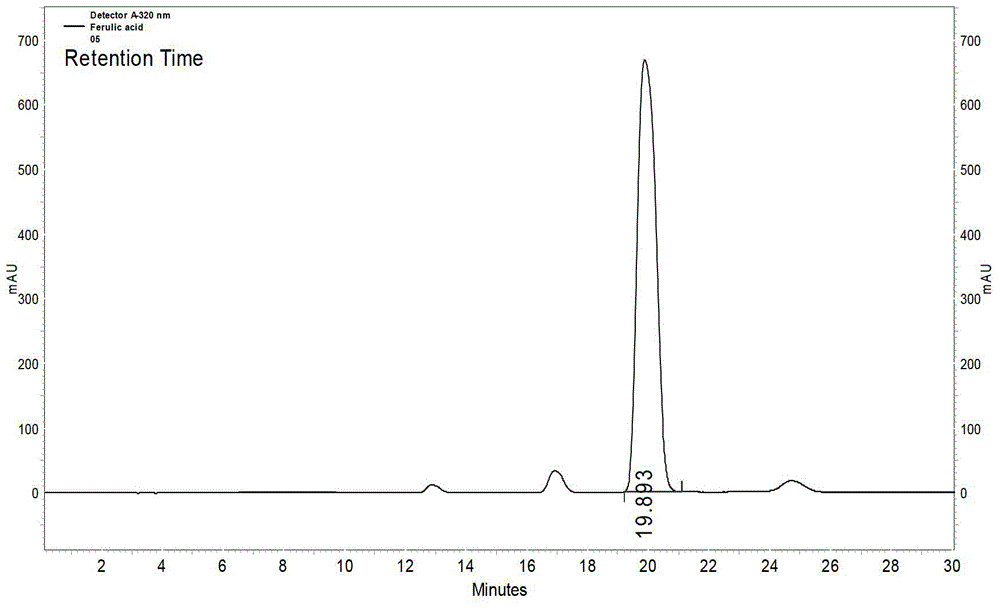

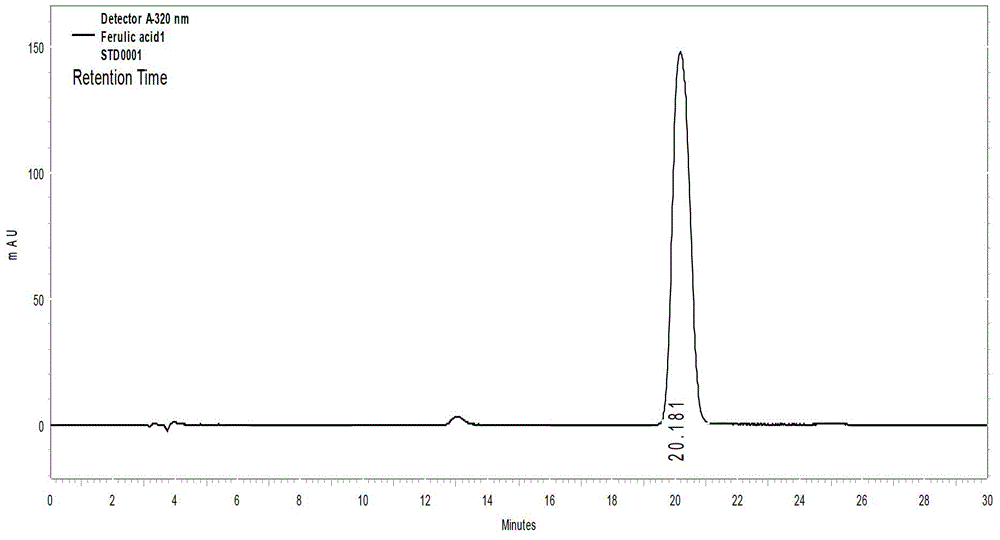

Image

Examples

Embodiment 1

[0035] Embodiment 1: utilize corn bran to prepare ferulic acid

[0036] (1) Pretreatment of raw materials:

[0037] Take a certain amount of corn husks, dry them at 105°C until the water content is 5%, grind them through a 40-mesh sieve with a grinder, and obtain the pretreated raw materials.

[0038] (2) Alkali alcohol treatment to obtain crude ferulic acid:

[0039] The raw material pretreated in step (1) is mixed with a solid-to-liquid ratio of 1 kg: 10 liters and a 2:50:50 (w / v / v) aqueous alkali alcohol solution (a mixed solution of sodium hydroxide: ethanol: water), 80 Extract at ℃ for 2.5 hours, centrifuge and filter in a three-legged centrifuge, and the filter residue can be used to prepare oligosaccharides;

[0040] The obtained filtrate is subjected to ultrafiltration with a membrane with a molecular weight cut-off of 5000 to further remove soluble macromolecular substances, and the permeate is used for future use.

[0041] (3) Obtaining ferulic acid:

[0042] The...

Embodiment 2

[0043] Embodiment 2: utilize wheat bran to prepare ferulic acid

[0044] (1) Pretreatment of raw materials:

[0045] Take a certain amount of wheat bran, dry it at 105°C to a water content of 2%, and pulverize it with a pulverizer (the degree of pulverization is 60 mesh) to obtain the pretreated raw material.

[0046] (2) Alkali alcohol treatment to obtain crude ferulic acid:

[0047] The raw material pretreated in step (1) is mixed with a solid-to-liquid ratio of 1 kg: 15 liters and a 3:60:40 (w / v / v) aqueous alkali alcohol solution (mixed solution of potassium hydroxide: ethanol: water), 60 Extract at ℃ for 4 hours and centrifuge in a three-legged centrifuge.

[0048] The centrifugate is further removed by ultrafiltration equipment with a membrane molecular weight cut-off of 10,000 and 2,000, and the permeate is used for standby.

[0049] (3) Obtaining high-purity ferulic acid:

[0050] The permeate in step (2) is subjected to nanofiltration treatment. The treatment step...

Embodiment 3

[0051] Embodiment 3: utilize bagasse to prepare ferulic acid

[0052] (1) Pretreatment of raw materials:

[0053] Take a certain amount of bagasse and grind it through a pulverizer (the degree of crushing is 20 mesh), and then dry it at 105°C until the water content is 5%.

[0054] (2) Alkali alcohol treatment to obtain crude ferulic acid:

[0055]The raw material pretreated in step (1) is mixed with a solid-to-liquid ratio of 1 kg: 12 liters and a 4:70:30 (w / v / v) alkali alcohol aqueous solution (sodium hydroxide: ethanol: water mixed solution), continuously Stir, extract at 40°C for 7 hours, and centrifuge in a three-legged centrifuge.

[0056] The centrifugate is further removed by ultrafiltration equipment with a membrane molecular weight cut-off of 20,000 and 1,000, and the permeate is used for standby.

[0057] (3) Obtaining ferulic acid:

[0058] The permeate in step (2) is subjected to nanofiltration treatment. The treatment steps of the permeate with nanofiltratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com