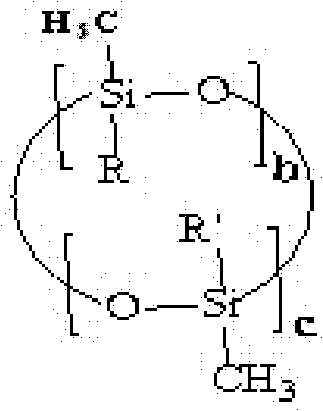

A kind of high-performance organosilicon epoxy material and its preparation method and application

An organosilicon epoxy and cyclosiloxane technology, applied in epoxy resin coatings, epoxy resin adhesives, organic insulators, etc., can solve the problems of failing to take into account material transmittance, high interfacial tension, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

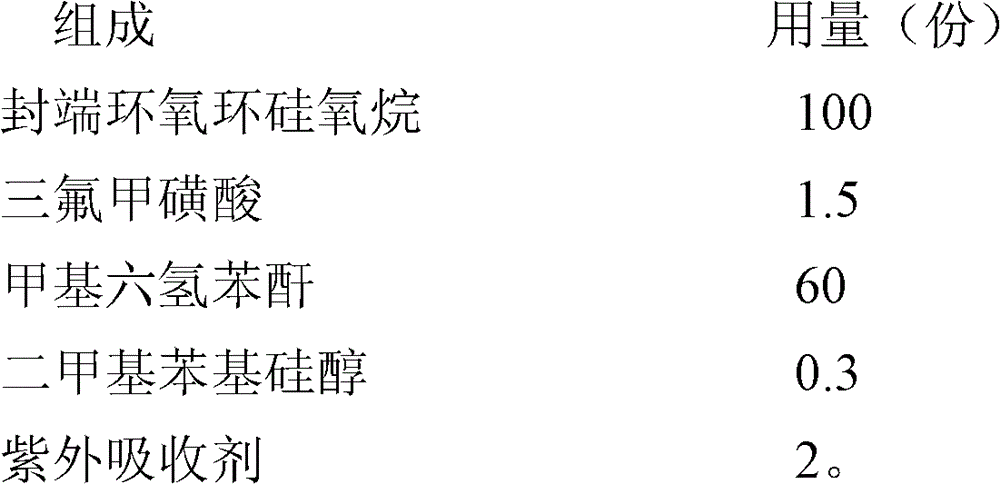

Embodiment 1

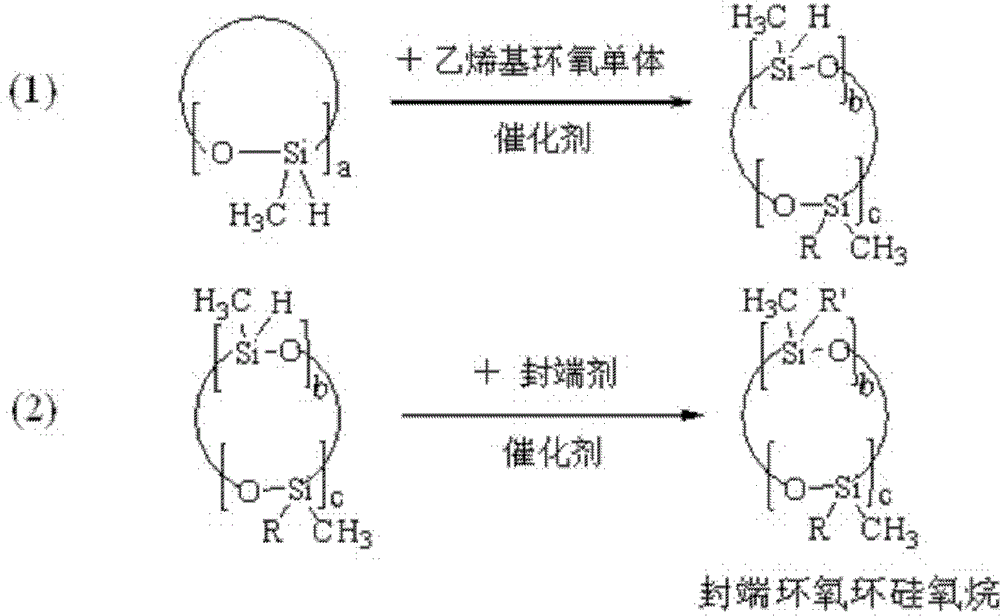

[0052] The preparation method of silicone epoxy material is as follows:

[0053] (1) Preparation of end-capped epoxy cyclosiloxane: add 0.5mol (90.1g) 1,3,5-trimethylcyclosiloxane to a round-bottomed flask equipped with a stirrer, reflux condenser, thermometer, and nitrogen port Trisiloxane C 3 h 12 o 3 Si 3 (provided by Beijing Huawei Ruike Chemical Co., Ltd.), 1.0mol (114.1g) allyl glycidyl ether (CH 2 =CHCH 2 OCH 2 CHCH 2O, supplied by Energy Chemical) and 100ml cyclohexane, feed high-purity nitrogen into the reactor at room temperature and stir evenly, then gradually heat up to 70°C, and slowly add 0.4ml dropwise after the temperature is constant, the concentration is 1g The chloroplatinic acid tetrahydrofuran solution of / 160ml is used as catalyzer, after dropwise addition, react 8h, add 59.3g capping agent n-butanol and 0.15ml above-mentioned chloroplatinic acid tetrahydrofuran solution in reactor, continue reaction 6h again, after reaction finishes, The solvent ...

Embodiment 2

[0058] The preparation method of silicone epoxy material is as follows:

[0059] (1) Preparation of end-capped epoxy cyclosiloxane: add 0.5mol (120.2g) 1,3,5,7-tetramethyl to a round bottom flask equipped with a stirrer, reflux condenser, thermometer, and nitrogen port Cyclotetrasiloxane C 4 h 16 o 4 Si 4 (Quzhou Ruilijie Chemical Co., Ltd. provides), 0.5mol (62.1g) 1,2-epoxy-4-vinyl epoxycyclohexane ( CH 2 = CHC 6 h 9 O, provided by SigmaAldrich) and 150ml of xylene, feed high-purity nitrogen into the reactor at room temperature and stir evenly, then gradually heat up to 60°C, after the temperature is constant, slowly add 3.22ml of chloroplatinic acid with a concentration of 1g / 160ml The isopropanol solution is used as a catalyst. After the dropwise addition, after 2 hours of reaction, add 176.7g end-capping agent 1-heptene and 2.52ml of the above-mentioned chloroplatinic acid isopropanol solution in the reactor, and then continue to react for 6h. After the reaction, ...

Embodiment 3

[0065] The preparation method of silicone epoxy material is as follows:

[0066] (1) Preparation of end-capped epoxy cyclosiloxane: add 0.5mol (180.4g) 1,3,5,7,9 in a round bottom flask equipped with a stirrer, reflux condenser, thermometer, nitrogen port, 11-Hexamethylcyclohexasiloxane C 6 h 24 o 6 Si 6 (provided by KingstonChemistry), 3.5mol (434.63g) 1,2-epoxy-4-vinylcyclohexane (CH 2 =CHC 6 h 9 O, Provided by SigmaAldrich) and 100ml of toluene, feed high-purity nitrogen into the reactor at room temperature and stir evenly, then gradually heat up to 100°C, after the temperature is constant, add 0.10ml of dicyclopentadiene platinum dichloride with a concentration of 1g / 160ml dropwise Ethanol solution was used as a catalyst. After 24 hours of reaction, 20.0 g of capping agent ethanol and 0.01 ml of the above-mentioned dicyclopentadiene platinum dichloride ethanol solution were added to the reactor, and the solvent toluene and excess unreacted 1 were removed by rotary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com