Method for preparing high-activity pancreatin

A high-activity, pancreatic enzyme technology, applied in the direction of pancreatic enzymes, can solve the problems of large differences in activity and destruction of the three enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

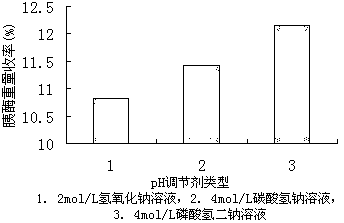

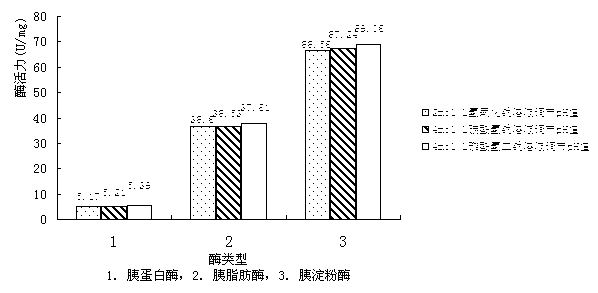

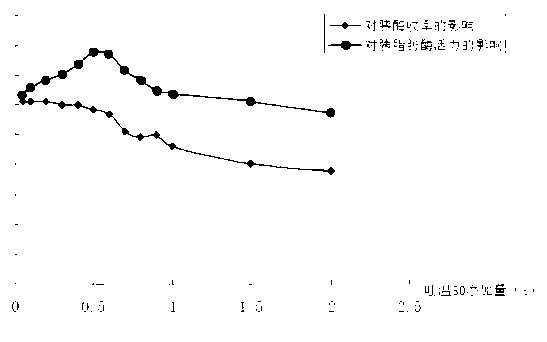

[0020] This example examines the effect of extracting pancreatin with the extract composed of this formula. Add 2% CaCl to 50g pancreatic residue 2 Solution 100ml, stir well, and add 0.5% NH 4 Cl, 0.5% NaCl, 1% sucrose, 1% starch, 1% glycerol and 0.5% Tween 80, while using 4molL -1 Na 2 HPO 4 Adjust pH6.5-7.0. Let cool to 4°C, add 30% PEG 260mL, stir for 30min, place in a refrigerator at 4°C for 1h, siphon the supernatant, centrifuge at 3500rpm for 10min, degrease the precipitate twice with twice the volume of cold acetone, once with ether, and dry to obtain trypsin . The activities of trypsin, pancreatic lipase and pancreatic amylase in pancreatic enzymes were determined by the method of Chinese Pharmacopoeia 2010 edition. with no added NH 4 Cl, sucrose, starch, glycerol and Tween 80 extracts were extracted for comparison. The comparison results are shown in Table 1. The yield of trypsin has increased by 16%, and the activities of the three enzymes have been signific...

example 2

[0023] This example examines NH 4 The stimulant effect of Cl addition on the enzyme activity of pancreatic lipase. Control group except without NH 4 Except for Cl, all the others were operated as described above. results in the removal of NH 4 After Cl, the yield of trypsin, trypsin and amylase hardly changed, and the activity of trypsin decreased by 2.6%. The results are shown in Table 2.

[0024]

example 3

[0026] This example investigates the protective effect of sucrose on pancreatic enzymes. After removing 1% of sucrose from the combined protective agent, the activities of the three enzymes in the obtained pancreatic enzymes are all reduced, trypsin is reduced by 3.7%, pancreatic amylase is reduced by 5.3%, and pancreatic fat The enzyme decreased by 5.6%, and the yield of trypsin did not change significantly (Table 3).

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com