Micro-fluidic agglutinin chip for glycosyl separation, and preparation method thereof

A lectin and microfluidic technology, applied in the preparation of test samples, laboratory containers, chemical instruments and methods, etc., can solve the problems of cumbersome operation steps, achieve enhanced contact area, good reproducibility, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

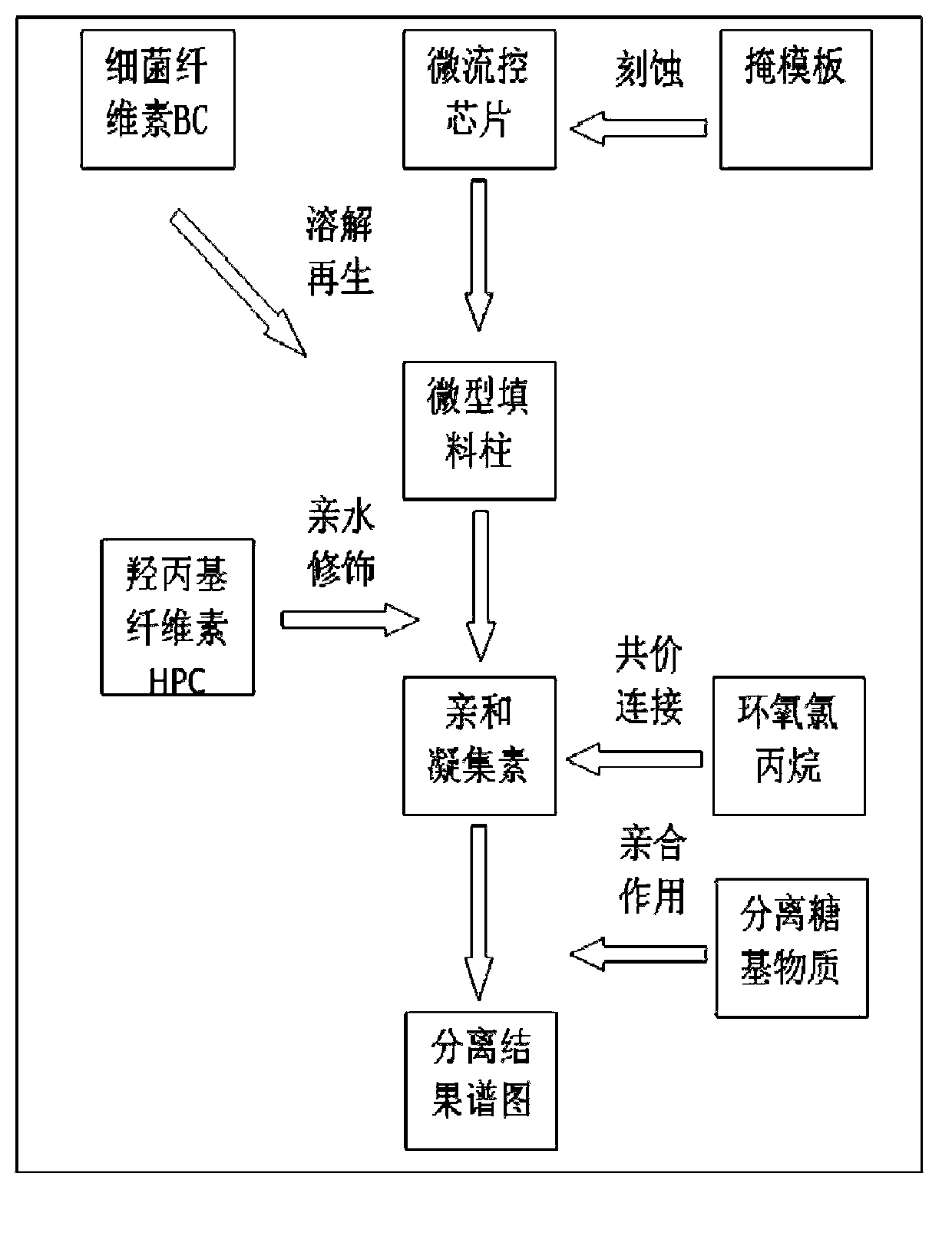

[0023] A method for preparing a microfluidic lectin chip for glycosyl separation of the present invention, the specific steps are as follows:

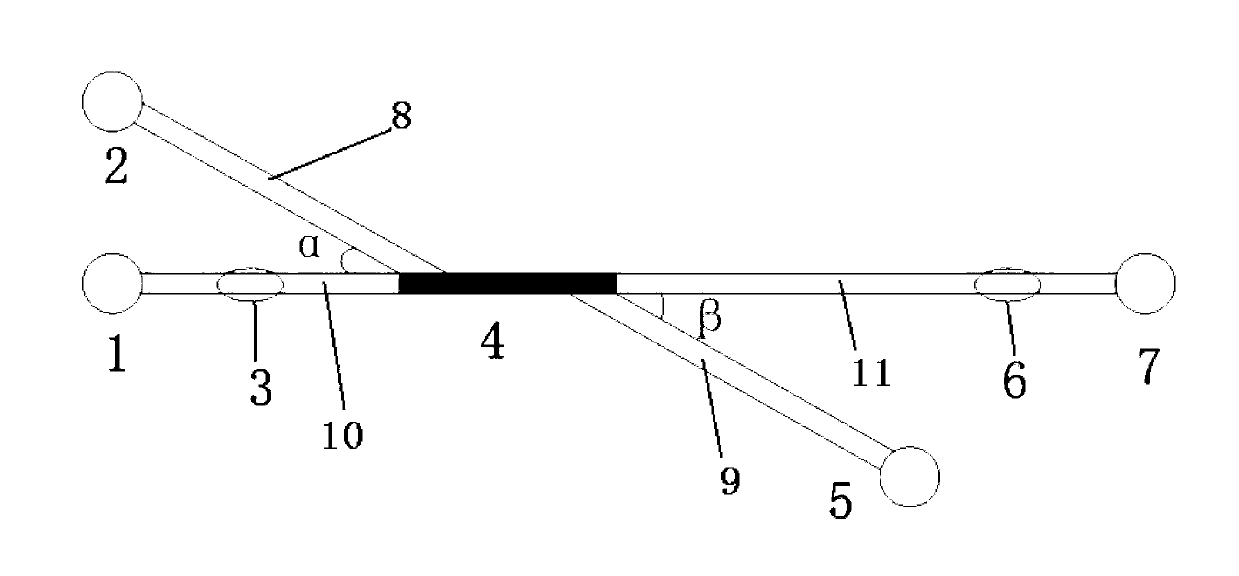

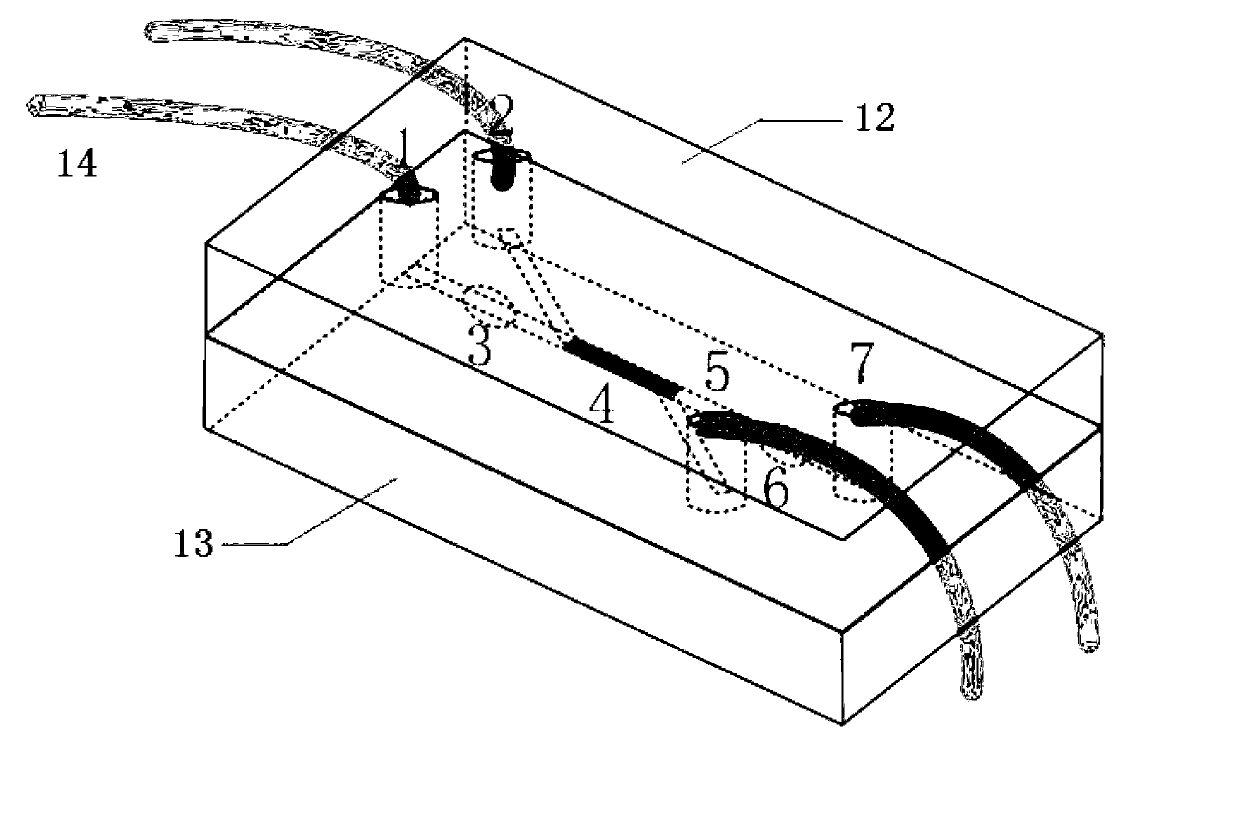

[0024] Step 1, adopt AutoCAD software to draw channel graphics, import the designed channel graphics into Adobe Illustrator and print on the film to make a mask by a high-resolution printer (resolution greater than 3000dpi); wherein, the microstructure lines made by the mask plate The width is 0, the channel width is 10-400 μm, the radius of the four entrances and exits is 20-100 μm, and the length of the micro-column is 20-400 mm; the channel pattern includes the micro-column channel and the sample channel, and the micro-column channel includes the front Part 8, micro-column 4, micro-column channel rear 9, the sample channel includes a sample channel front 10, a micro-column 4, a sample channel rear 11, and the sample channel front 10, micro-column 4, and sample channel rear 11 are located On the same horizontal line, the front part 8...

Embodiment 1

[0034] A method for preparing a microfluidic chip with the function of separating glycosyl compounds of the present invention comprises the following steps:

[0035] Step 1, adopt AutoCAD software to draw channel graphics, import the designed channel graphics into Adobe Illustrator and print on the film to make a mask by high-resolution printer (resolution greater than 3000dpi); Wherein, the graphic line width that described mask plate makes is zero, the channel width is 10 μm, the radius of the reservoir at the end of the channel is 20 μm, and the length of the microcolumn is 20 mm; α is 30°, and β is 40°.

[0036] Step 2: Use standard ultraviolet lithography to etch the microstructure on the mask on the chromium plate, turn on the lithography machine to preheat for 10 minutes, take out the chromium plate under yellow light, and place it on the stage for vacuum adsorption; Spread the mask on the chrome plate, press it with a clean polished glass sheet, perform exposure pre-op...

Embodiment 2

[0044] A method for preparing a microfluidic chip with the function of separating glycosyl compounds of the present invention comprises the following steps:

[0045] Step 1, adopt AutoCAD software to draw channel graphics, import the designed channel graphics into Adobe Illustrator and print on the film to make a mask by high-resolution printer (resolution greater than 3000dpi); Wherein, the graphic line width that described mask plate makes is zero, the channel width is 400 μm, the radius of the reservoir at the end of the channel is 100 μm, and the length of the microcolumn is 400 mm; α is 90°, and β is 60°.

[0046] Step 2: Use standard ultraviolet lithography to etch the microstructure on the mask on the chromium plate, turn on the photolithography machine to preheat for 20 minutes, take out the chromium plate under yellow light, and place it on the stage for vacuum adsorption; The mask is laid flat on the chrome plate, pressed with a clean polished glass sheet, and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com