A kind of wood flour composite foam material and preparation method thereof

A compound foaming and wood powder technology, applied in the field of polymer material preparation, can solve the problems of natural plant fiber inhomogeneous anisotropic materials, complex interface characteristics, poor compatibility, etc., achieve scientific and reasonable preparation methods, and improve product addition. good value and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0022] According to the composition of raw materials in Table 1, each raw material is selected according to the composition of raw materials, and the wood powder is preheated with glyoxal at 80-150 ° C to remove a large amount of water, and then mixed with plasticizer and surface treatment The agent was added to a high-speed mixer and kneaded at room temperature for 20 minutes to obtain plasticized wood powder. The plasticized wood powder and all other raw materials were added to an internal mixer and mixed at 100°C for 15 minutes to obtain a pre-plasticized material. Enter into the open mill, knead evenly at 80°C, and plasticize completely to obtain plasticized materials, and finally add extruder to granulate at 120°C, and the obtained pellets are air-cooled to obtain the wood powder composite foaming material .

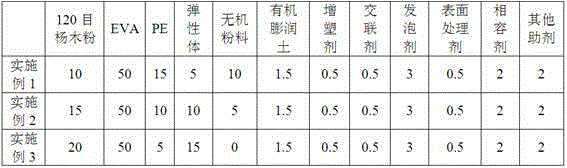

[0023] Table 1 Blending formula of 120 mesh wood flour composite foaming material (%)

[0024]

[0025] Among them, the elastomer is POE, the inorganic powder i...

Embodiment 4~6

[0027] According to the composition of the raw materials in Table 2, each raw material was taken, and the processing steps and process parameters were the same as those in Example 1 to obtain a wood flour composite foaming material.

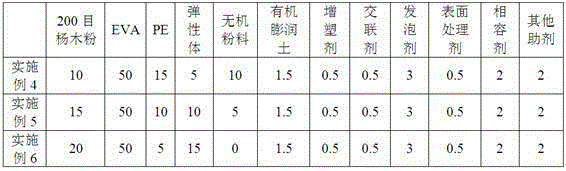

[0028] Table 2 Blending formula of 200 mesh poplar wood flour composite foaming material (%)

[0029]

[0030] Among them, the elastomer is POE, the inorganic powder is talcum powder and kaolin, the ratio of talc powder and kaolin is 5:1, the desiccant is glyoxal, the plasticizer is glycerin and absolute ethanol, the ratio of glycerin and absolute ethanol The cross-linking agent is dicumyl peroxide, the blowing agent is azodicarbonamide and sodium bicarbonate, the ratio of azodicarbonamide and sodium bicarbonate is 3.5:1.5, and the surface treatment agent is Silane coupling agent, solubilizer is epoxy resin and ethylene acrylate. The ratio of epoxy resin to ethylene acrylate is 1:3, other additives are zinc oxide and zinc stearate, and the ra...

Embodiment 7~9

[0032] According to the composition of raw materials in Table 3, each raw material was taken, and the processing steps and process parameters were the same as those in Example 1 to obtain a wood flour composite foaming material.

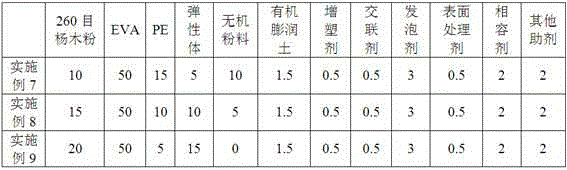

[0033] Table 3 Blending formula of 260 mesh wood flour composite foaming material (%)

[0034]

[0035] Among them, the elastomer is POE, the inorganic powder is talcum powder and kaolin, the ratio of talc powder and kaolin is 5:1, the desiccant is glyoxal, the plasticizer is glycerin and absolute ethanol, the ratio of glycerin and absolute ethanol The cross-linking agent is dicumyl peroxide, the blowing agent is azodicarbonamide and sodium bicarbonate, the ratio of azodicarbonamide and sodium bicarbonate is 3.5:1.5, and the surface treatment agent is Silane coupling agent, solubilizer is epoxy resin and ethylene acrylate. The ratio of epoxy resin to ethylene acrylate is 1:3, other additives are zinc oxide and zinc stearate, and the ratio of zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com