Phosphorus-series reaction-type flame-retardant unsaturated polyester resin

A reactive flame retardant and polyester resin technology, applied in the field of polyester resin, can solve the problems of losing market position, high price, insufficient strength, etc., and achieve the effect of good curing performance, cheap price and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

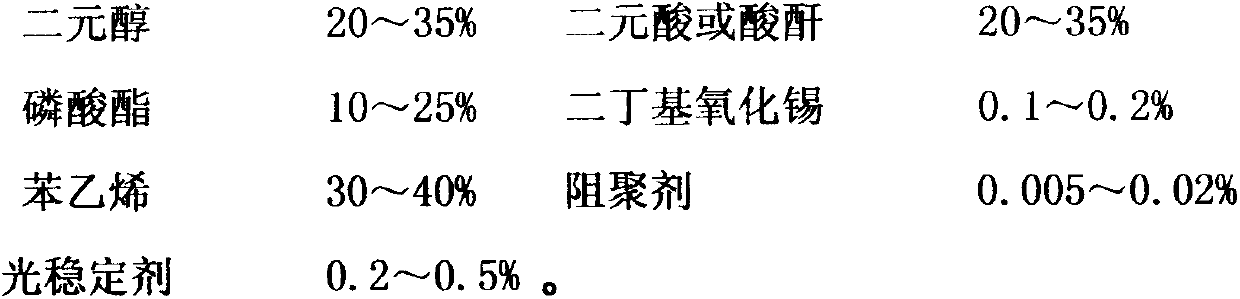

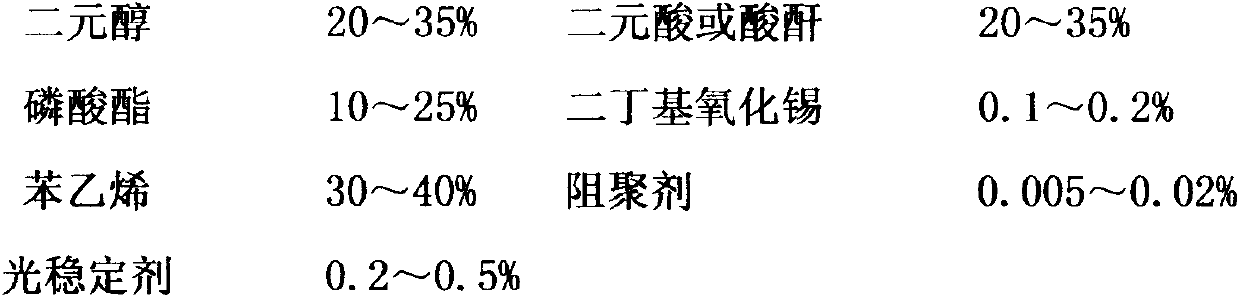

Method used

Image

Examples

Embodiment 1

[0030] Add 228.48 grams (3.00mol) of propylene glycol, 388.98 grams (6.27mol) of ethylene glycol, 182.65 grams (1.23mol) of phthalic anhydride, and 429.73 g (4.38 mol) of dianhydride, gradually raise the temperature to 210°C, control the head temperature below 102°C, conduct polycondensation reaction for 6-8 hours until the shrinkage is 80.8-85.8g, cool down to 160°C, add methylphosphoric acid Dimethyl ester 370.28 grams (2.98mol) and catalyst dibutyltin oxide 1.6g, react at 160°C for 4-5 hours, until the amount of methanol released is 90.6-95.36g, then gradually increase the material temperature, at 180-190°C React for 3-4 hours, then react under reduced pressure for 2-3 hours at a vacuum degree below -0.095mPa.s, add 0.2g of hydroquinone after the vacuum is released, cool down to 120°C, and add 700g of diluent styrene After diluting and stirring evenly, add 3.7 grams of methyl 2-hydroxybenzoate and 3.7 grams of 2,2-dihydroxy-4,4-dimethoxybenzophenone to obtain a transparent ...

Embodiment 2

[0032] Add 211.88 grams (2.78mol) of propylene glycol, 360.32 grams (5.81mol) of ethylene glycol, 169.35 grams (1.14mol) of phthalic anhydride, 398.51 g (4.06 mol) of dianhydride, gradually increase the temperature to 210°C, control the head temperature below 102°C, conduct polycondensation for 6-8 hours until the shrinkage is 74.88-79.56g, then cool down to 160°C, add ethyl phosphoric acid Diethyl ester 459.95 grams (2.77mol) and catalyst dibutyltin oxide 1.6g, reacted 4-5 hours at 160 ℃, after the ethanol amount that deviates is 121.05-127.42g, raise material temperature gradually, at 180-190 ℃ reaction for 3-4 hours, and then under the vacuum degree below -0.095mPa.s, vacuum pressure reduction reaction for 2-3 hours, after the vacuum is released, add 0.2g hydroquinone, cool down to 120 ℃, add diluent styrene 700 Dilute with 1 gram, stir evenly, add 3.7 grams of 2-hydroxybenzoic acid methyl ester and 3.7 grams of 2,2-dihydroxy-4,4-dimethoxybenzophenone to obtain transparent ...

Embodiment 3

[0034] Add 425.07 grams (5.59mol) of propylene glycol in the 2L four-necked flask that is equipped with stirrer, thermometer and rectifying tower, 278.80 grams (2.68mol) of neopentyl glycol, 182.67 grams (1.10mol) of isophthalic acid, be warming up gradually to 210°C, the temperature of the distillation head is controlled below 102°C, the polycondensation reaction is 6-8 hours, and after the shrinkage is 19.8-23.8g, the temperature is lowered to 160°C, and 383.23 grams (3.91mol) of maleic anhydride is added, and the temperature is gradually raised to 210°C, the temperature of the distillation head is controlled below 102°C, and the polycondensation reaction is carried out for 4 hours. After the shrinkage is 68.2-73.6g, the temperature is lowered to 160°C, and 330.22 grams (2.66mol) of dimethyl methyl phosphate and the catalyst dibutyl Tin oxide 1.6g, react at 160°C for 4-5 hours, until the amount of methanol released is 90.6-95.36g, then gradually increase the material temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com