Compatible product and preparation method of russula cultivation material

A production method and cultivation material technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of unreasonable use of branches, increase of production costs, random discarding, etc., and achieve the purpose of broadening the channels of cultivation raw materials and water retention Strong, good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

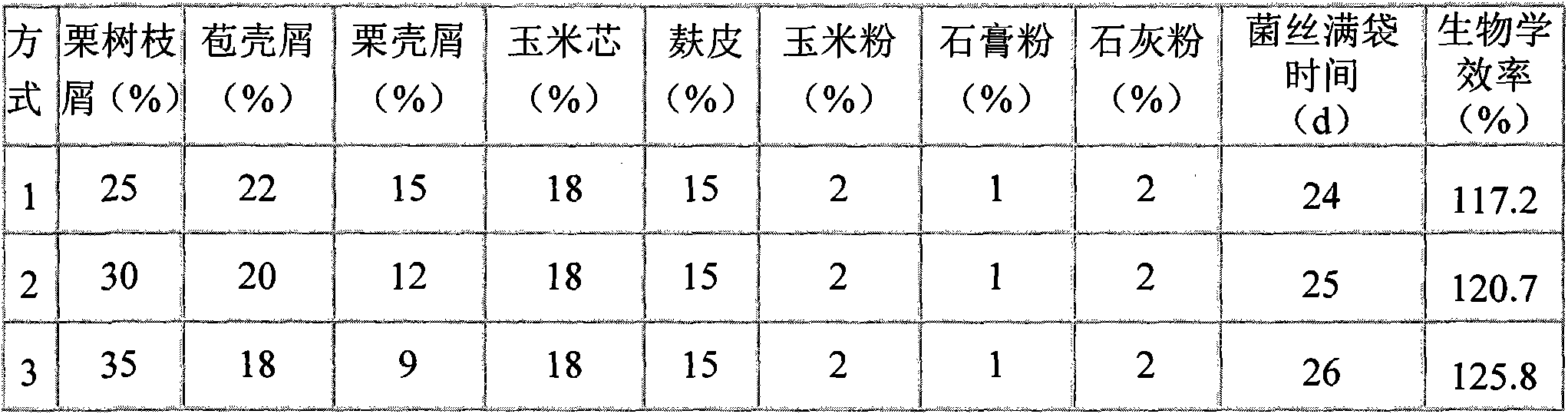

[0029] Mode 1: In this embodiment, the russula cultivation material includes the following components and mass proportions: 25% of chestnut twigs, 22% of bract husks, 15% of chestnut husks, 18% of corncobs, 15% of bran, corn flour 2%, gypsum powder 1%, and lime powder 2%, all of which are the quality of dry matter, and the sum of the proportioning is 100%.

[0030] Production Method:

[0031] ①Sunning: Expose the raw materials for 2 days before mixing;

[0032] 2. Pre-wet: First, mix chestnut twigs, bract crumbs, and chestnut husks evenly in a dry state, and then pre-wet (fully soak) with 2% lime aqueous solution;

[0033] ③ Stacking and fermentation: Pile the wet material into a trapezoidal pile with a height of 1.2m and a width of 3m. After the pile is completed, pat the surroundings lightly, and then use a wooden stick with a diameter of 15cm to insert some vertical air holes on the pile to reach the bottom of the pile. Pore density is 1 / m 3 , and finally covered with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com