Environment-friendly room temperature curing organic silicon high-temperature resistant coating and preparation method thereof

A technology of high temperature resistant coating and room temperature curing, applied in coating and other directions, can solve the problems of silicone coating requiring heating and curing, unsatisfactory temperature resistance and heat insulation effect, etc., saving construction energy consumption, good heat insulation and high temperature resistance , Good fuel oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

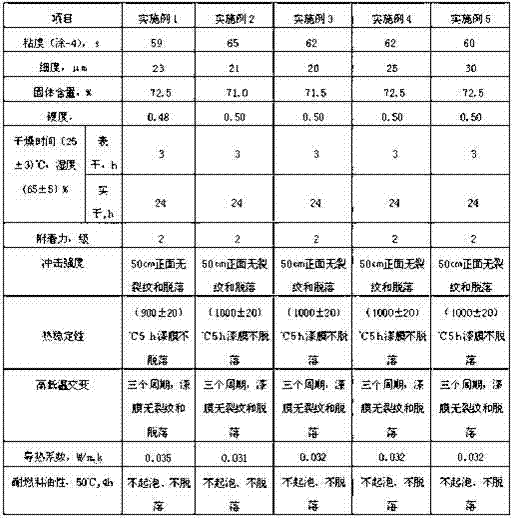

Examples

Embodiment 1

[0040] (1) Add ethanol and silicone dry resin dissolved in ethanol into the container, mix well, and then add rutile titanium dioxide, heat insulation material, kaolin, and zinc phosphate in sequence under stirring, stir for 15 minutes until uniform, and grind To the specified fineness, the paint component A is obtained;

[0041] (2) Mix the raw materials of component B evenly to obtain component B;

[0042] (3) When using, mix component A and component B according to the weight ratio of 20:1.

[0043] Among them, the ethanol solution of silicone resin, ethanol, rutile titanium dioxide, heat insulation material, kaolin, and zinc phosphate are in a weight ratio of 55:3:10:25:4:3, and the heat insulation material includes mica powder, aluminum silicate fiber, and oxide The aluminum short fiber weight ratio is 12:8:5.

[0044] In component B, absolute ethanol: triethylenetetramine: cobalt naphthenate: n-butyl titanate are prepared in a weight ratio of 50:40:5:5.

Embodiment 2

[0046] The preparation method is the same as in Example 1, wherein the weight ratio of the ethanol solution of silicone resin, ethanol, rutile titanium dioxide, heat insulating material, kaolin, and zinc phosphate is 45:5:5:38:3:4, and the mica in the heat insulating material The weight ratio of powder, aluminum silicate fiber and alumina short fiber is 10:8:20.

[0047] In component B, absolute ethanol: triethylenetetramine: cobalt naphthenate: n-butyl titanate are prepared in a ratio of 50:40:5:5, and the ratio of components A and B is 25:1 respectively.

Embodiment 3

[0049] The preparation method is the same as in Example 1, wherein the weight ratio of the ethanol solution of silicone resin, ethanol, pigment chromium trioxide, heat insulating material, kaolin, and zinc phosphate is 45:5:5:38:3:4, and the heat insulating material The weight ratio of mica powder, aluminum silicate fiber and alumina short fiber is 10:8:20.

[0050] In component B, absolute ethanol: triethylenetetramine: cobalt naphthenate: n-butyl titanate are prepared in a ratio of 50:40:5:5, and the ratio of components A and B is 25:1 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com