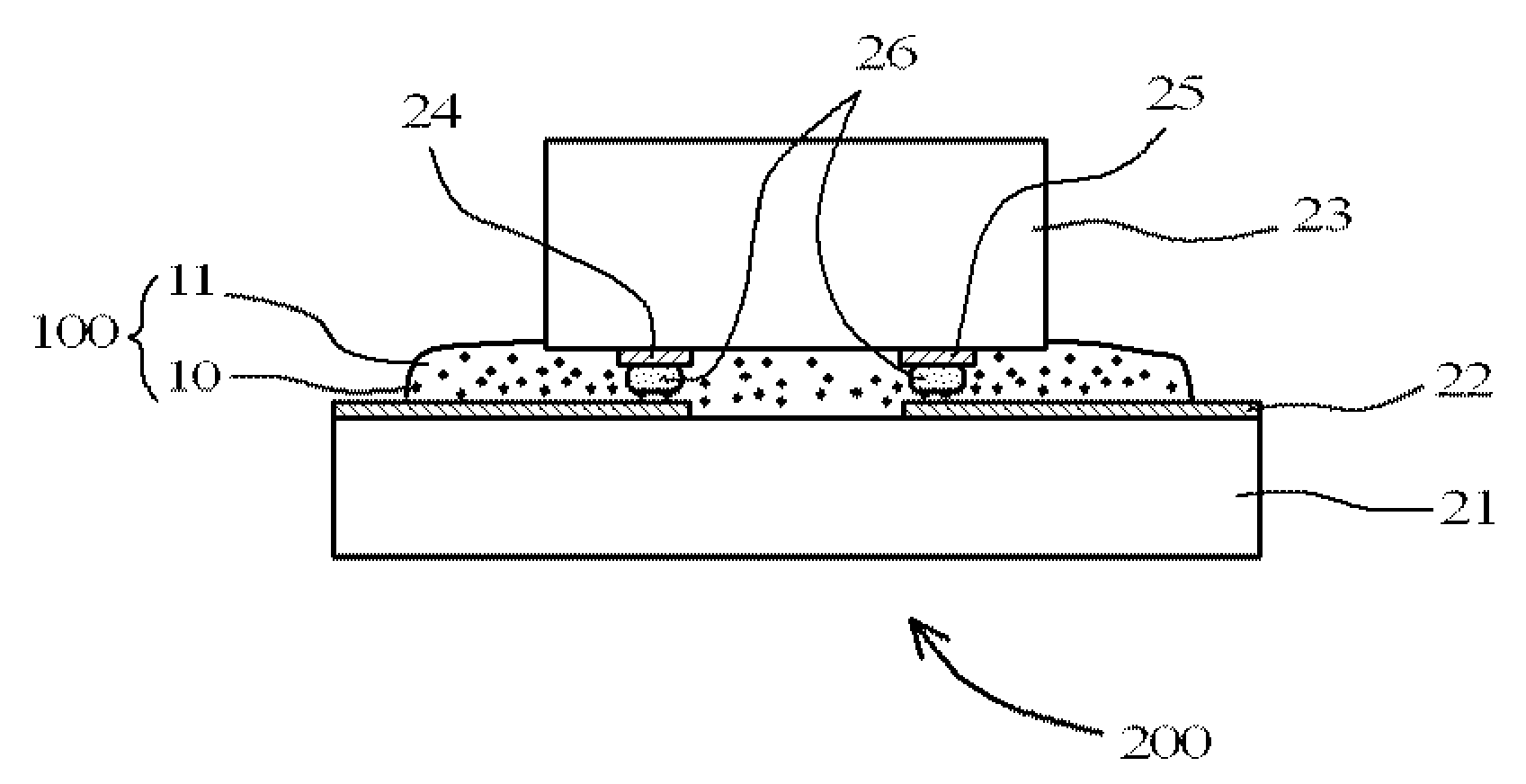

Light-reflecting anisotropically conductive adhesive and light emitting device

A conductive adhesive, anisotropic technology, used in conductive adhesives, adhesives, conductive materials, etc., can solve the problems of luminous efficiency (reduced light extraction efficiency, reduced total luminous flux of reflectivity, etc.), and achieve chip shear strength. The effect of reducing the wavelength dependence and improving the luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

[0090] Embodiment 1~7, comparative example 1~4

[0091] A thermosetting resin composition was prepared by uniformly mixing the components in the compounding amounts (parts by mass) shown in Table 1 except for the conductive particles and the light-reflective insulating particles using an ordinary stand mixer. 10phr [parts per hundred resin] of Au particles and 30phr of light-reflective insulating particles were added to this thermosetting resin composition, and uniformly mixed with a stand mixer to obtain a white-looking light-reflective anisotropic conductive adhesive.

Embodiment 6

[0093] (Titanium oxide-coated silver particles (reflective insulating particles) used in Example 6)

[0094] 5g of granular silver particles (average particle diameter of 1.0 μm) and 50ml of toluene were dropped into the flask attached to the mixer, and 0.25g of silane coupling agent (3-methacryloxypropane) was dropped into the flask while stirring. Triethoxysilane), stirred at 25°C for 60 minutes. Then, 2 g of methyl methacrylate, 2 g of 2-hydroxyethyl methacrylate, 0.04 g of benzoyl peroxide and 1 g of 2,4-toluene diisocyanate were added to the mixture, and the After stirring for 12 hours, insulating-coated silver particles were obtained as light-reflective insulating particles. The average particle diameter of the light-reflective insulating particles including the insulating coating was 5.0 μm.

Embodiment 7

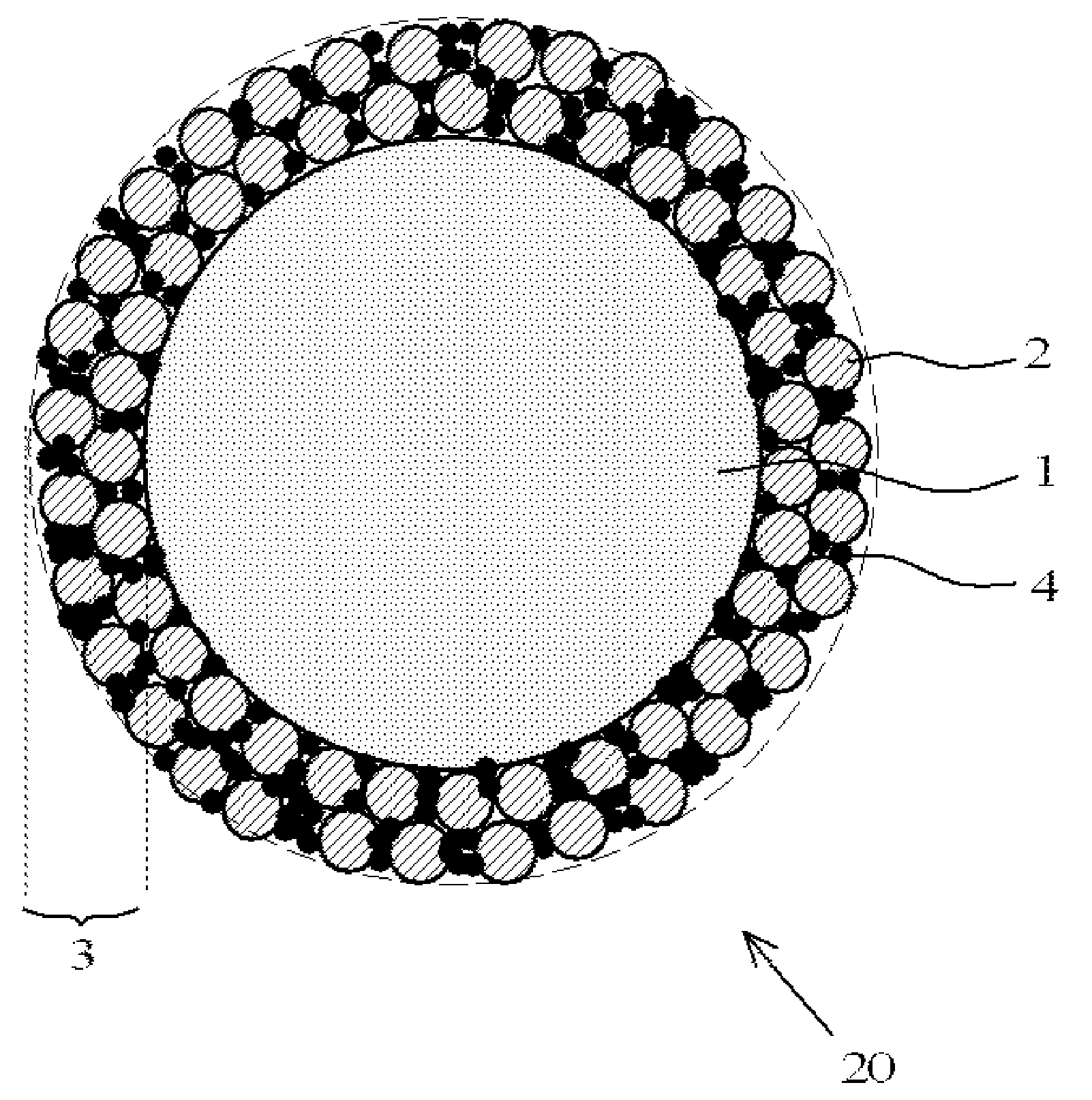

[0095] (Titanium oxide-coated gold particles (reflective conductive particles) used in Example 7)

[0096] Titanium oxide powder with an average particle size of 0.5 μm and Au-coated resin conductive particles with an average particle size of 5 μm in brown color (spherical acrylic resin particles with an average particle size of 4.6 μm were subjected to electroless gold plating with a thickness of 0.2 μm) The obtained particles) were put into a mechanical fusion device, and a light-reflective layer of about 0.5 μm thick made of titanium oxide particles was formed on the surface of the conductive particles to obtain light-reflective conductive particles. The appearance color of the reflective conductive particles is gray.

[0097]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com