Cooling fluid containing solid hollow particle

A technology of hollow particles and cooling fluid, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems that the geometric structure and scale of nano-fluids are not easy to control, the thermal conductivity of the fluid has no obvious contribution, and the heat carried by the fluid is increased. It is not easy to achieve Settling or build-up problems, enhanced liquid convective heat transfer, enhanced fluid turbulence effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

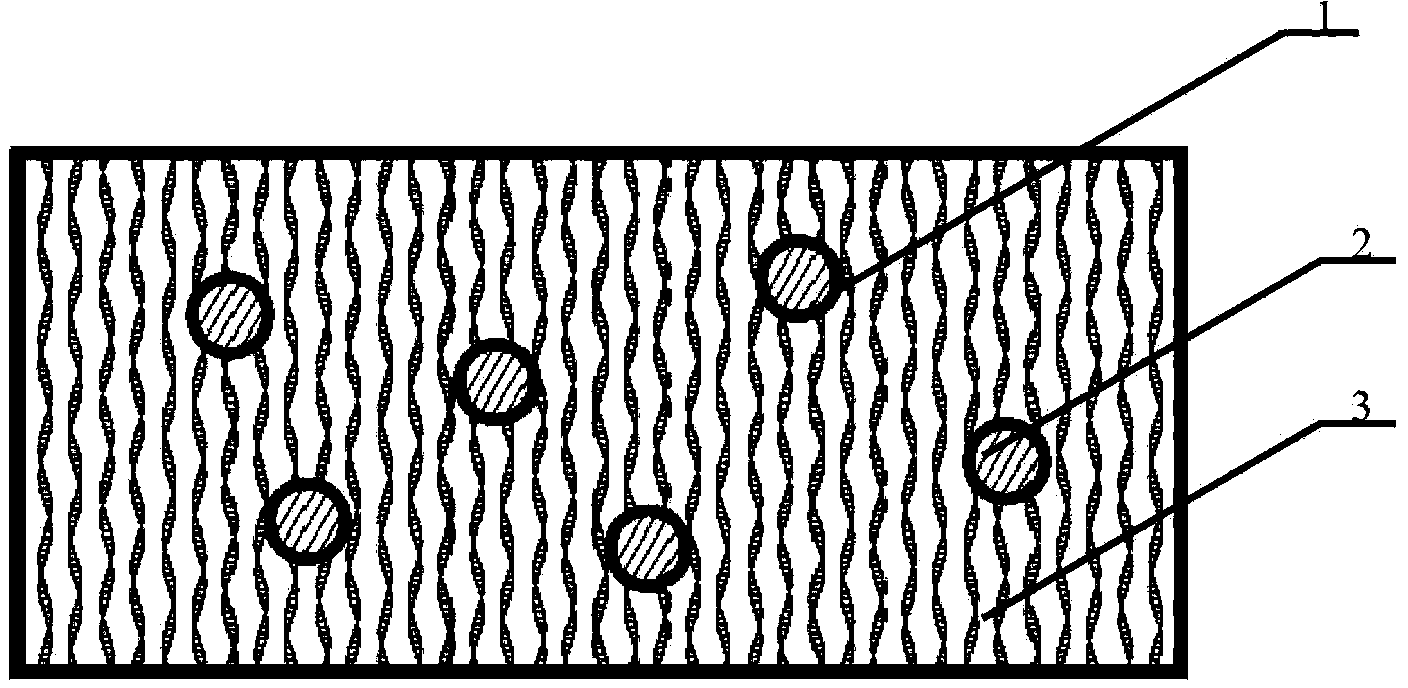

[0027] gallium indium alloy Ga 80 In 20 For solvent 1, copper / aluminum double-layer solid hollow particles are uniformly dispersed in gallium indium alloy, see figure 1 .

[0028] The copper 2 is deposited on the surface of the aluminum 3 by spraying to form a double-coated particle structure. The outer diameter of the particles in this example is 1 mm, and the shell thickness is 1 μm. The density of the particles is 6.5g / cm 3 , gallium indium alloy density is 6.6g / cm 3 .. The volume fraction of the particles in the gallium-indium alloy is 5%, and the thermal conductivity of the obtained cooling fluid is 45W / mK.

[0029] Because both copper and aluminum have extremely high thermal conductivity, the thermal conductivity of the composite liquid is effectively enhanced. At the same time, the composite of copper / aluminum can make the density of the particles consistent with that of gallium indium alloy. Finally, the outer copper clad layer can isolate the contact between a...

Embodiment 2

[0031] Water is used as a solvent, and aluminum solid hollow particles are uniformly dispersed in cooling fluid in water. The volume fraction of particles in water is 10%.

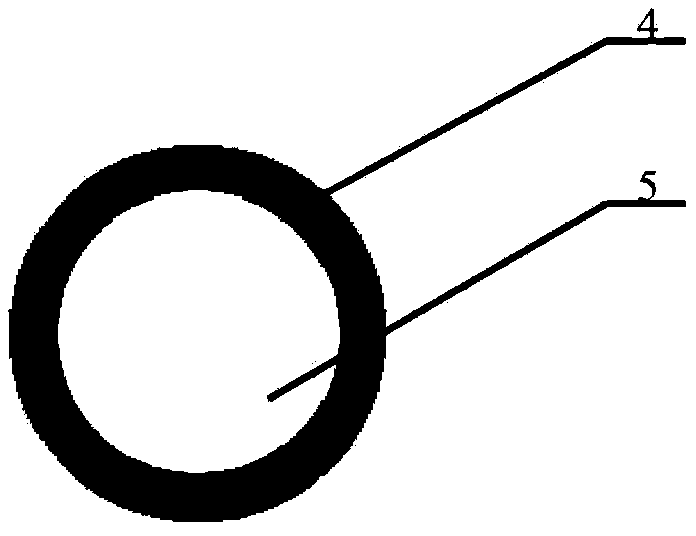

[0032] figure 2 It is the structural diagram of aluminum solid hollow particles in this embodiment. The aluminum hollow particles in this embodiment are made by cold extrusion process. The diameter of the solid hollow particle is 100 μm, and the thickness of the aluminum shell 4 is 20 μm. The density of hollow particles is 1.2g / cm 3 . The thermal conductivity of the resulting cooling fluid was 1.2 W / mK. The composite coating of aluminum 4 and air 5 can ensure that the density of the particles is consistent with that of water, and the particles can be stably suspended in the solvent.

Embodiment 3

[0034] A cooling fluid in which copper / silicon dioxide double-layer solid hollow particles are uniformly dispersed in gallium indium tin alloy.

[0035] In this embodiment, the cooling fluid structure and figure 1 Similar, but its multi-layer particles use sol-gel method to deposit silicon dioxide (non-metal) on the surface of copper hollow particles to form a double-layer coating structure. In this embodiment, the copper / silicon dioxide double-layer solid hollow particles have a diameter of 10 μm. Among them, the core diameter of the copper hollow particles is 6 μm, and the thickness of the silicon dioxide layer is 2 μm. The overall density of the particles is 6.7g / cm 3 , suspended in the gallium indium tin alloy, the volume fraction of the particles in the gallium indium tin alloy is 50%, and the thermal conductivity of the obtained cooling fluid is 200W / mK.

[0036] Because silicon dioxide has a strong affinity for gallium indium tin alloy, the copper particles coated wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com