Preparation method of porous polyquaternary phosphorus ionic liquid

A polyquaternary phosphorus type, ionic liquid technology, applied in the field of material chemistry, can solve problems such as cumbersome methods and inability to achieve large-scale production applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the porous polyquaternary phosphine-type ionic liquid includes specific steps: first, the quaternary phosphorus-type ionic liquid as the basic framework material is added to the porogenic solvent, then the polymerization initiator azobisisobutyronitrile is added, and the basic framework material , The mass ratio of the porogenic solvent and the polymerization initiator is 1:2~40:0.003~0.01, then stirred and polymerized at 60°C~240°C for 6~24 hours, and finally recovered the solvent by distillation at 120°C to obtain Porous polyquaternary ionic liquid. The prepared porous polyquaternary phosphine ionic liquid has a pore diameter of 0.3-200nm and a specific surface area of 370-760m 2 / g between.

[0029] The preparation method of the quaternary phosphorus-type ionic liquid includes: adding vinyl-containing triphenylphosphine and haloalkane to any liquid in toluene, acetone, ethanol or tetrahydrofuran at a molar ratio of 1:1 to 10 and stirred ...

Embodiment 1

[0037] Add 100 mmol of p-bromostyrene to a tetrahydrofuran solution containing 200 mmol of magnesium powder, and stir at room temperature for 3 hours to obtain the Grignard reagent of p-bromostyrene, and then add 50 mmol of phenylphosphine dichloride to the above in situ The prepared p-bromostyrene Grignard reagent was stirred overnight at room temperature. After the reaction was completed, the unreacted Grignard reagent of p-bromostyrene was quenched with saturated ammonium chloride solution, and the obtained product was purified with a silica gel column, and rinsed with an eluent with a volume ratio of petroleum ether and ethyl acetate of 20:1 , to obtain divinyl triphenylphosphine monomer.

[0038] The preparation of vinyltriphenylphosphine and trivinyltriphenylphosphine is carried out according to the above steps respectively, except that 50mmol of phenylphosphine dichloride is replaced by 100mmol of diphenylphosphine chloride or 33mmol of phosphorus trichloride .

Embodiment 2

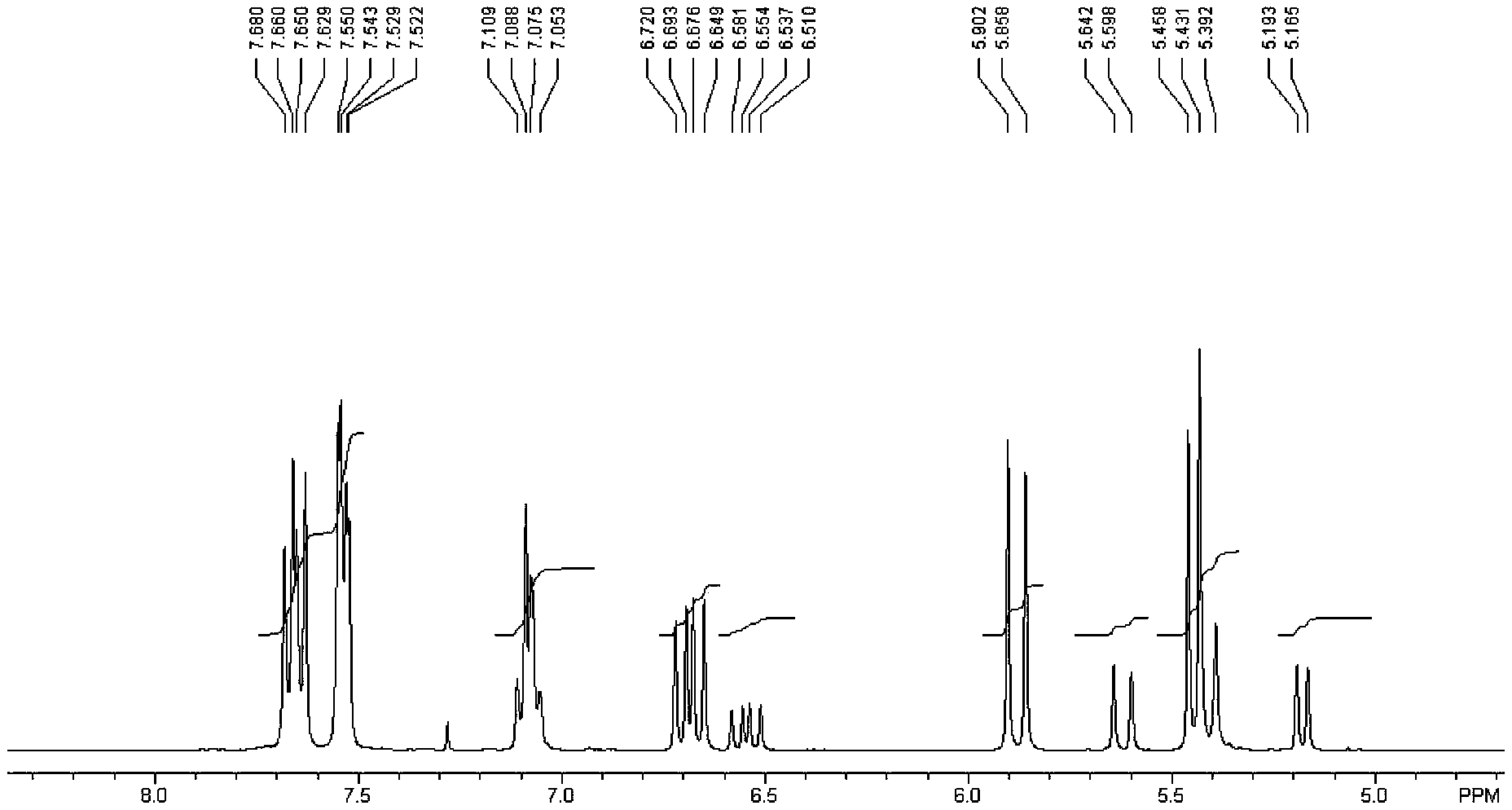

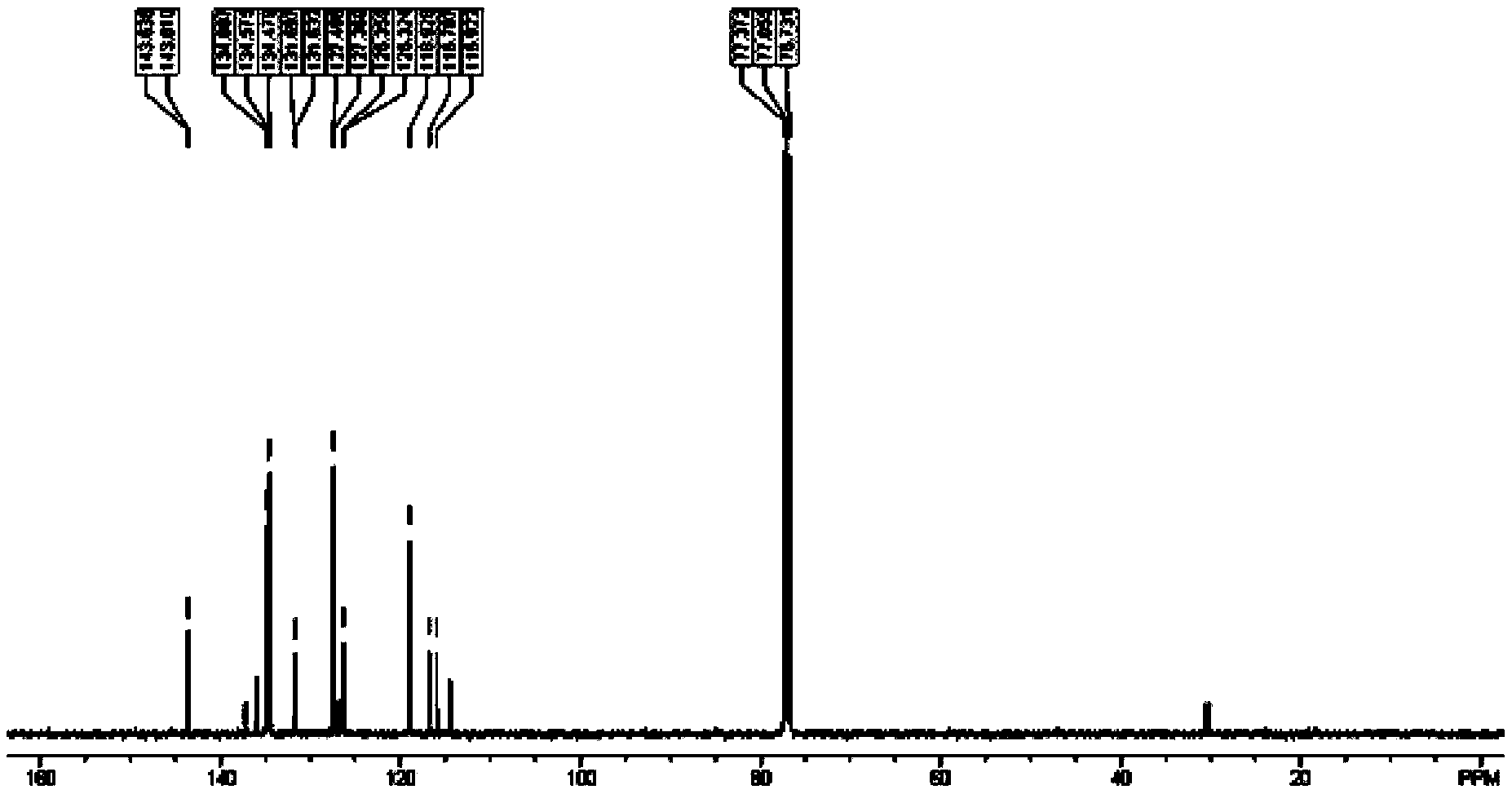

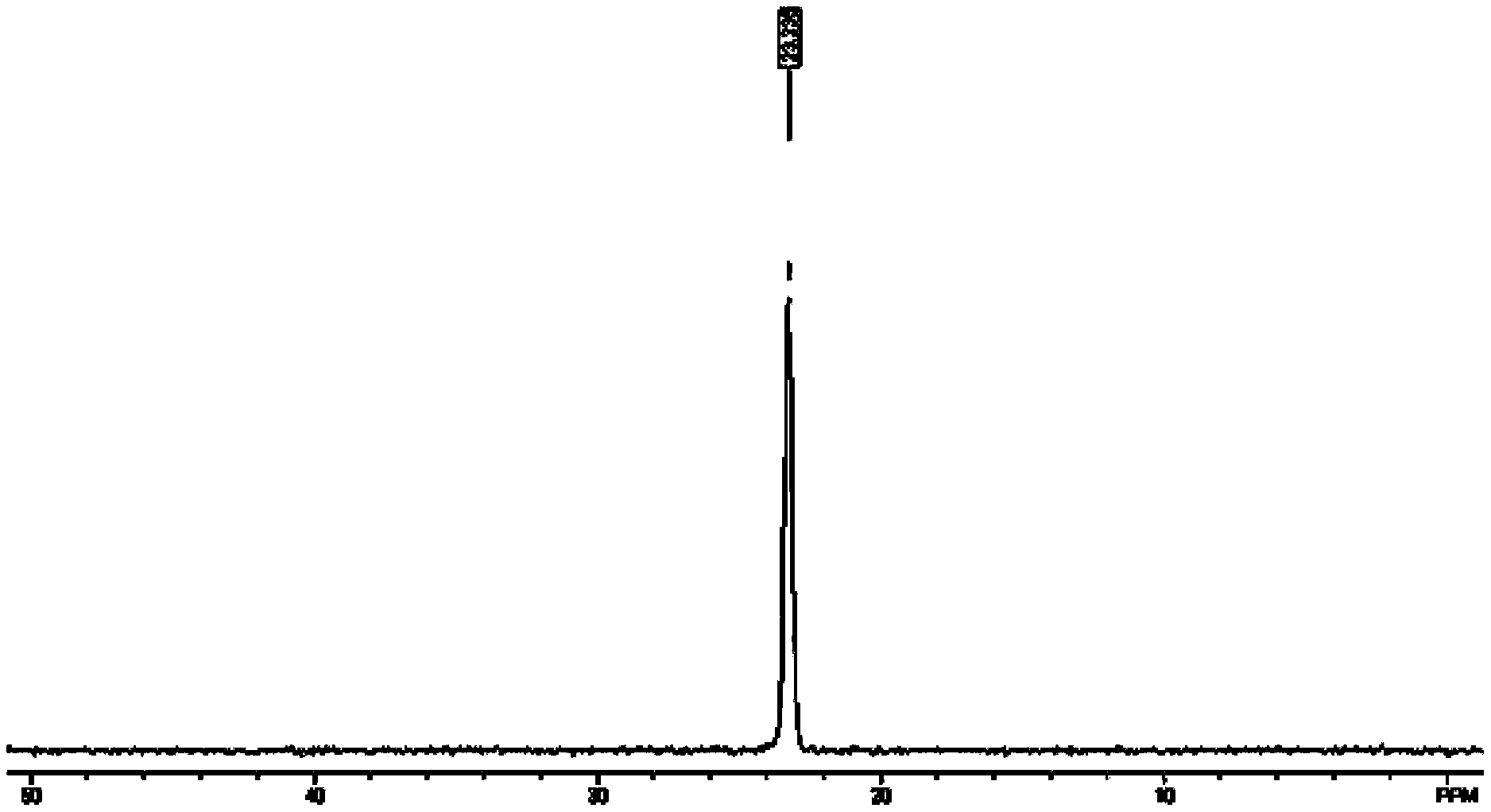

[0040] The 100 mmol trivinyltriphenylphosphine prepared by the method in Example 1 was added to 100 mL of toluene solution containing 100 mmol p-vinylbenzyl chloride, and refluxed at 110 ° C for 48 h, cooled to room temperature, and Evaporate the toluene under reduced pressure with the evaporator, and wash the unreacted reactant with diethyl ether to obtain 4-vinylbenzyl tri-(vinyltriphenyl) phosphorus chloride monomer, whose structure is figure 1 , figure 2 and image 3 to make sure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com