Water-fast wood adhesive and preparation method thereof

A wood adhesive and formaldehyde solution technology, applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve the problems of poor water resistance, limited application scope, low bonding strength, etc., and achieve high adhesive strength and low price. , The effect of good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

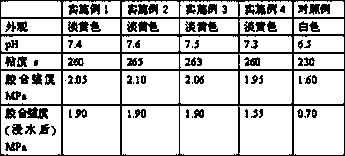

Examples

Embodiment 1

[0021] Weigh the raw materials with the following weights:

[0022] Plant starch 70Kg, rosin pentaerythritol ester 3Kg, hydrogenated rosin glyceride 2Kg, barium sulfate 4Kg, p-toluene sulfinic acid amine 1Kg, ammonium chloride 2Kg, magnesium oxide 5Kg, potassium persulfate 3Kg, polyvinyl alcohol 7Kg, butyl latex 4Kg , resorcinol 9Kg, microcrystalline paraffin 8Kg, butyl methacrylate 3Kg, triammonium citrate 5Kg, calcium carbonate 3Kg, phenol 7Kg, 2-benzyl-4-chlorophenol 3Kg, formaldehyde solution 20Kg, urea 3Kg, Melamine 1Kg, sodium hydroxide 10Kg, surfactant 3Kg, sodium hexadecylbenzenesulfonate 3Kg, water 70Kg.

[0023] The above-mentioned vegetable starch is wheat starch.

[0024] The mass concentration of above-mentioned formaldehyde aqueous solution is preferably 30%.

[0025] The above-mentioned microcrystalline paraffin has a melting point of 84°C.

[0026] The preparation method is:

[0027] Vegetable starch, rosin pentaerythritol ester, hydrogenated rosin glycerid...

Embodiment 2

[0030] Weigh the raw materials with the following weights:

[0031] Plant starch 80Kg, rosin pentaerythritol ester 5Kg, hydrogenated rosin glyceride 4Kg, barium sulfate 7Kg, p-toluene sulfinic acid amine 2Kg, ammonium chloride 3Kg, magnesium oxide 8Kg, potassium persulfate 5Kg, polyvinyl alcohol 12Kg, butyl latex 7Kg , resorcinol 15Kg, microcrystalline paraffin 14Kg, butyl methacrylate 6Kg, triammonium citrate 8Kg, calcium carbonate 5Kg, phenol 15Kg, 2-benzyl-4-chlorophenol 5Kg, formaldehyde solution 30Kg, urea 8Kg, Melamine 2Kg, sodium hydroxide 20Kg, surfactant 9Kg, sodium hexadecylbenzenesulfonate 5Kg, water 100Kg.

[0032] What above-mentioned vegetable starch adopted is potato starch.

[0033] The mass concentration of the above-mentioned formaldehyde solution is 35%.

[0034] The above-mentioned microcrystalline paraffin has a melting point of 84°C.

[0035] The preparation method is:

[0036] Vegetable starch, rosin pentaerythritol ester, hydrogenated rosin glycerid...

Embodiment 3

[0039] Weigh the raw materials with the following weights:

[0040] Plant starch 75Kg, rosin pentaerythritol ester 4Kg, hydrogenated rosin glyceride 3Kg, barium sulfate 6Kg, p-toluene sulfinic acid amine 1Kg, ammonium chloride 2Kg, magnesium oxide 7Kg, potassium persulfate 4Kg, polyvinyl alcohol 10Kg, butyl latex 6Kg , resorcinol 11Kg, microcrystalline paraffin 12Kg, butyl methacrylate 5Kg, triammonium citrate 6Kg, calcium carbonate 4Kg, phenol 12Kg, 2-benzyl-4-chlorophenol 4Kg, formaldehyde solution 22Kg, urea 5Kg, Melamine 2Kg, sodium hydroxide 15Kg, surfactant 5Kg, sodium hexadecylbenzenesulfonate 4Kg, water 85Kg.

[0041] The above-mentioned vegetable starch is tapioca starch.

[0042] The mass concentration of the above-mentioned formaldehyde solution is 32%.

[0043] The above-mentioned microcrystalline paraffin has a melting point of 84°C.

[0044] The preparation method is:

[0045] Vegetable starch, rosin pentaerythritol ester, hydrogenated rosin glyceride, barium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com