Immobilized laccase microballoon carrier and its preparation method and use

A technology for immobilizing laccase and carrier, applied in the direction of fixing on/in organic carrier, chemical instrument and method, water/sludge/sewage treatment, etc., can solve the problem of poor biocompatibility, glass bead surface Difficult functionalization and other problems, to achieve the effect of low cost, mild conditions and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

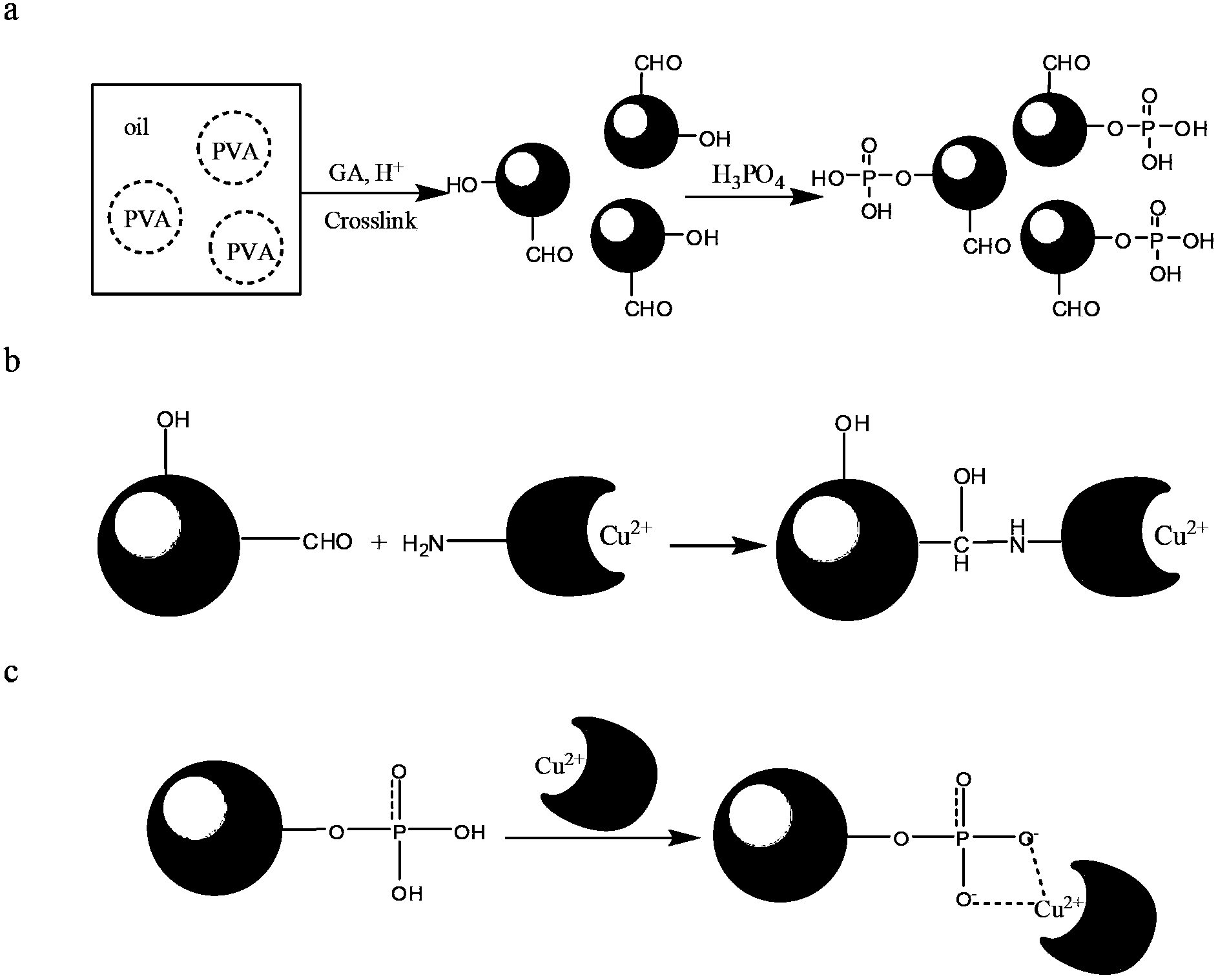

[0035] Embodiment 1, the preparation of immobilized laccase

[0036] 1) Preparation of immobilized laccase carrier:

[0037] Dissolve 3g of PVA (1799) in 30ml of water, stir mechanically in a boiling water bath for 1 hour, remove from the boiling water bath, wait until the reactant is cooled to 50°C, add 60ml of liquid paraffin. At room temperature, stir the mixture at 500rpm (the radius of the stirring blade is 2cm) for 2 hours to form microspheres, then add 1ml of 1mol L -1 hydrochloric acid solution and 2ml glutaraldehyde aqueous solution with a concentration of 50% by mass, at a rotation speed of 500rpm (the radius of the stirring paddle is 2cm), after stirring for 30 minutes, the microspheres are centrifuged at a rotation speed of 4000rpm (the radius of the centrifuge is 13.5cm) , washed three times with petroleum ether, and then vacuum-dried for 48 hours to obtain polyvinyl alcohol microspheres, the polyvinyl alcohol microspheres such as figure 2 shown. Depend on f...

Embodiment 2

[0042] Embodiment 2, the preparation of immobilized laccase

[0043] 1) Preparation of immobilized laccase carrier:

[0044]Dissolve 3g of PVA (1799) in 40ml of water, stir mechanically in a boiling water bath for 2 hours, remove from the boiling water bath, wait until the reactant is cooled to 80°C, add 80ml of liquid paraffin. At room temperature, the mixture was stirred at 1000rpm (the radius of the stirring blade was 2cm) for 24 hours to form microspheres, and then 2ml1mol L was added to a three-neck round bottom flask -1 hydrochloric acid solution and 3ml glutaraldehyde aqueous solution with a concentration of 50% by mass, at a rotation speed of 1000rpm (the radius of the stirring paddle is 2cm), after stirring for 60 minutes, the microspheres were separated by centrifugation at a rotation speed of 10000rpm (the radius of the centrifuge is 13.5cm) , washed three times with petroleum ether, and then vacuum-dried for 48 hours to obtain polyvinyl alcohol microspheres, the p...

Embodiment 3

[0049] Embodiment 3, the thermal stability of immobilized laccase

[0050] The immobilized laccase and free laccase prepared in Example 1 were respectively placed in a water bath at 30°C-70°C for 6 hours, and samples were taken to detect their enzyme activity. The enzyme activity detection was the same as in Example 1.

[0051] The results showed that the optimum temperature of immobilized laccase was 40°C, which was higher than the optimum temperature of free enzyme at 30°C, and within 30°C-70°C, the enzyme activity of immobilized laccase was higher than that of free enzyme. The activity of laccase, especially at 70°C, the retained activity of immobilized laccase can still reach 40.7%, while the activity of free laccase is only 7.4%, showing that the thermal stability of laccase is significantly improved after immobilization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com