Method for manufacturing graphene composite electrode

A graphene composite, graphene technology, applied in battery electrodes, capacitor electrodes, circuits, etc., can solve the problems of reducing the power density of supercapacitors, increasing the equivalent series resistance of electrodes, and complex electrode sheet processes, and achieving increased cycle stability. performance, reducing the equivalent series resistance, and easy and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

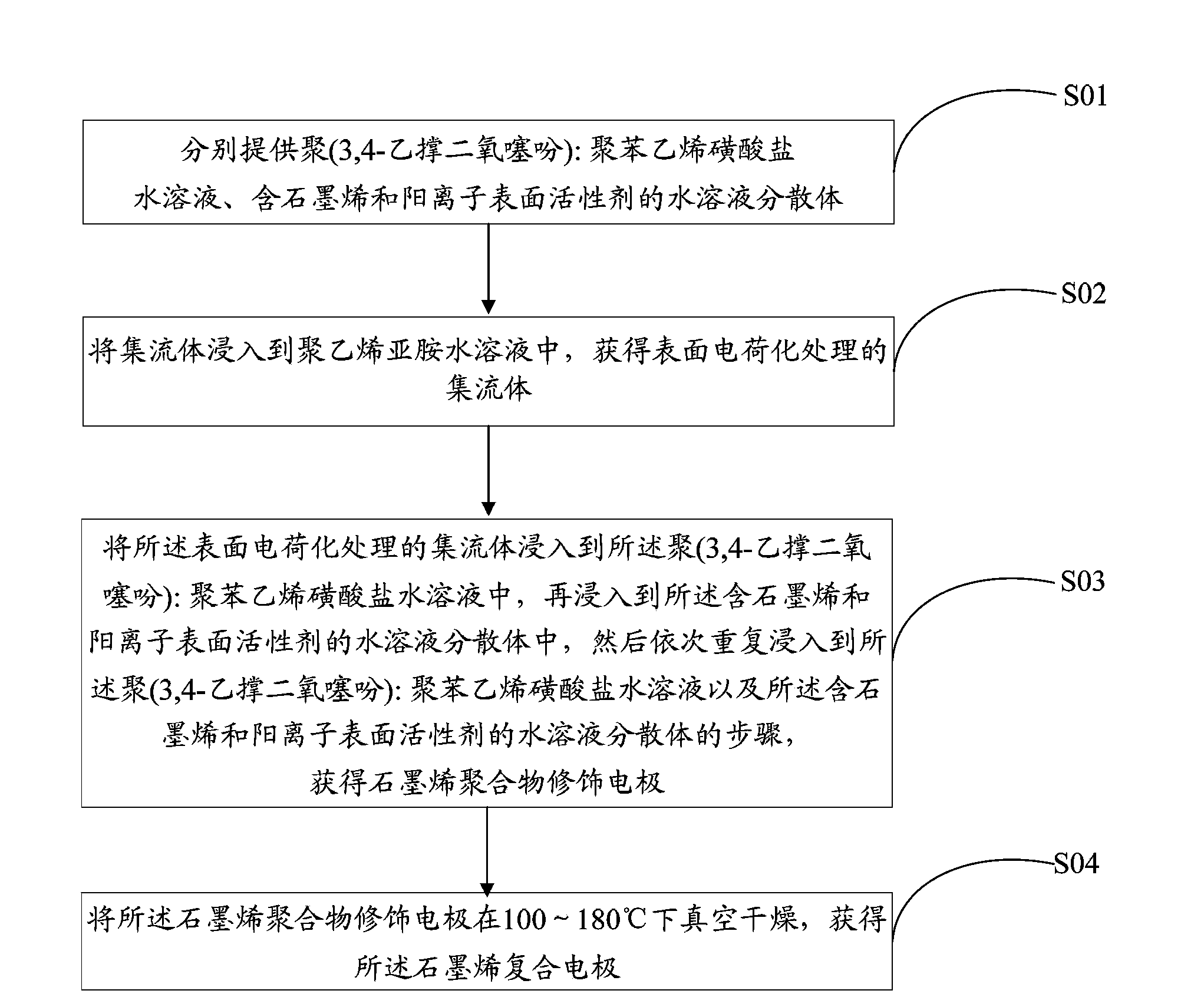

[0014] The embodiment of the present invention provides a kind of preparation method of graphene composite electrode, such as figure 1 As shown, it includes the following steps:

[0015] S01: Provide poly(3,4-ethylenedioxythiophene): polystyrene sulfonate aqueous solution, aqueous dispersion containing graphene and cationic surfactant;

[0016] S02: immersing the current collector in an aqueous polyethyleneimine solution to obtain a surface charge treated current collector;

[0017] S03: Immerse the current collector of the surface charge treatment into the poly(3,4-ethylenedioxythiophene): polystyrene sulfonate aqueous solution, and then immerse the graphene-containing and cationic surface active In the aqueous dispersion of agent, then repeatedly immersed in said poly(3,4-ethylenedioxythiophene): polystyrene sulfonate aqueous solution and the aqueous dispersion containing graphene and cationic surfactant Step, obtain graphene polymer modified electrode;

[0018] S04: dryi...

Embodiment 1

[0028] Preparation of PEDOT:PSS aqueous solution: Dissolve PSS in a certain amount of deionized water to prepare a solution with a concentration of 0.1 mg / mL, add EDOT dropwise to it (the molar ratio of PSS to EDOT monomer is 1:1), slowly Stir for 5 minutes, add dropwise hydrochloric acid, control the pH of the system to be 2, then slowly add ammonium persulfate [(NH4) 2 S 2 o 8 ] solution, its molar ratio with EDOT is 1:1, rapid stirring reaction 12h, obtains the PEDOT / PSS solution of 0.1mg / mL.

[0029] Preparation of graphene and cationic surfactant-containing aqueous dispersions: graphene and dodecyltrimethylammonium chloride are added to distilled water at a mass ratio of 1:1 for ultrasonic dispersion for 1 h, forming a graphene concentration of 0.1 mg / mL graphene and quaternary ammonium salt in water.

[0030] Place the 6μm copper foil in acetone, ethanol, and secondary water for 20 minutes for ultrasonic treatment. After the treatment is clean, rinse with a large amou...

Embodiment 2

[0034]Preparation of PEDOT:PSS aqueous solution: Dissolve PSS in a certain amount of deionized water to prepare a solution with a concentration of 5 mg / mL, add EDOT dropwise to it (the molar ratio of PSS to EDOT is 2:1), and stir slowly for 10 minutes , drop hydrochloric acid, control the pH of the system to be 3, then slowly add ammonium persulfate [(NH4) 2 S 2 o 8 ] solution, its molar ratio with EDOT is 2:1, rapid stirring reaction 12h, obtains the PEDOT / PSS solution of 5mg / mL.

[0035] Preparation of graphene and cationic surfactant-containing aqueous dispersion: graphene and triethanolammonium were added to distilled water at a mass ratio of 1:1 for ultrasonic dispersion for 5 hours to form graphene and triethanolammonium with a graphene concentration of 5 mg / mL. Aqueous solution of ethanolammonium.

[0036] Place the 20μm aluminum foil in acetone, ethanol, and secondary water for 30 minutes, and then wash it with a large amount of secondary water, dry it with nitrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com