Preparation and application of core-shell-structure bismuth sulfide@bismuth oxide composite microspheres

A technology of core-shell structure and bismuth sulfide, applied in chemical/physical processes, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low photocatalytic activity of bismuth oxide and low efficiency of photo-induced electron-hole separation, etc. problems, to achieve the effect of regular and controllable morphology, controllable crystal phase and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

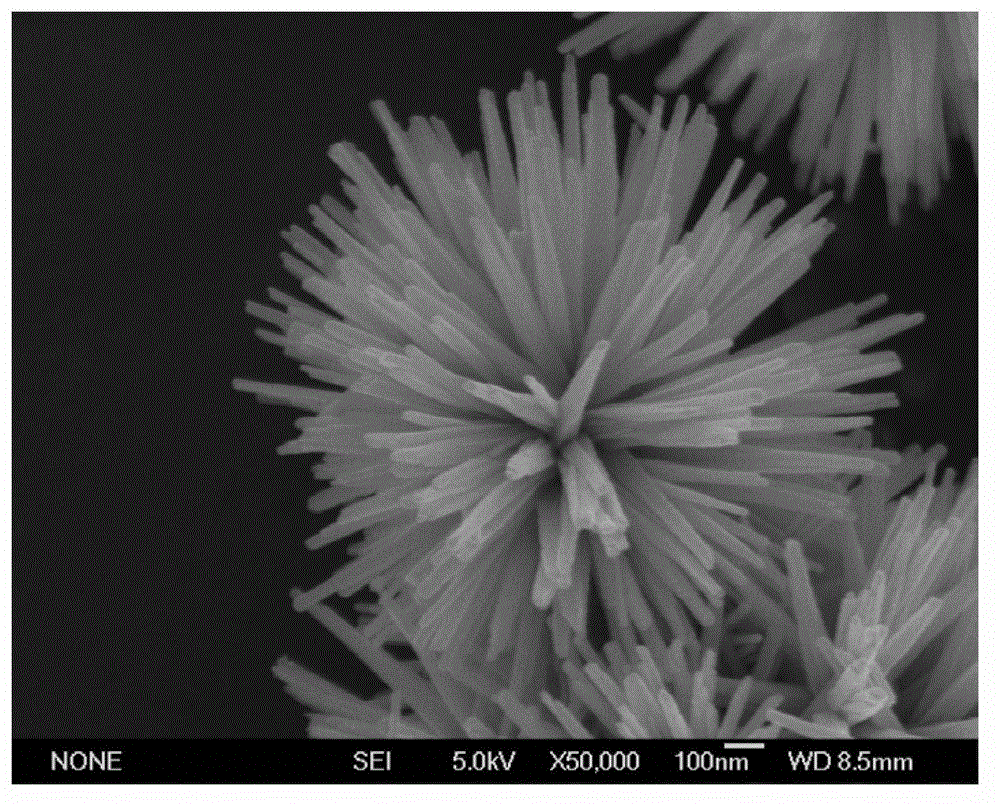

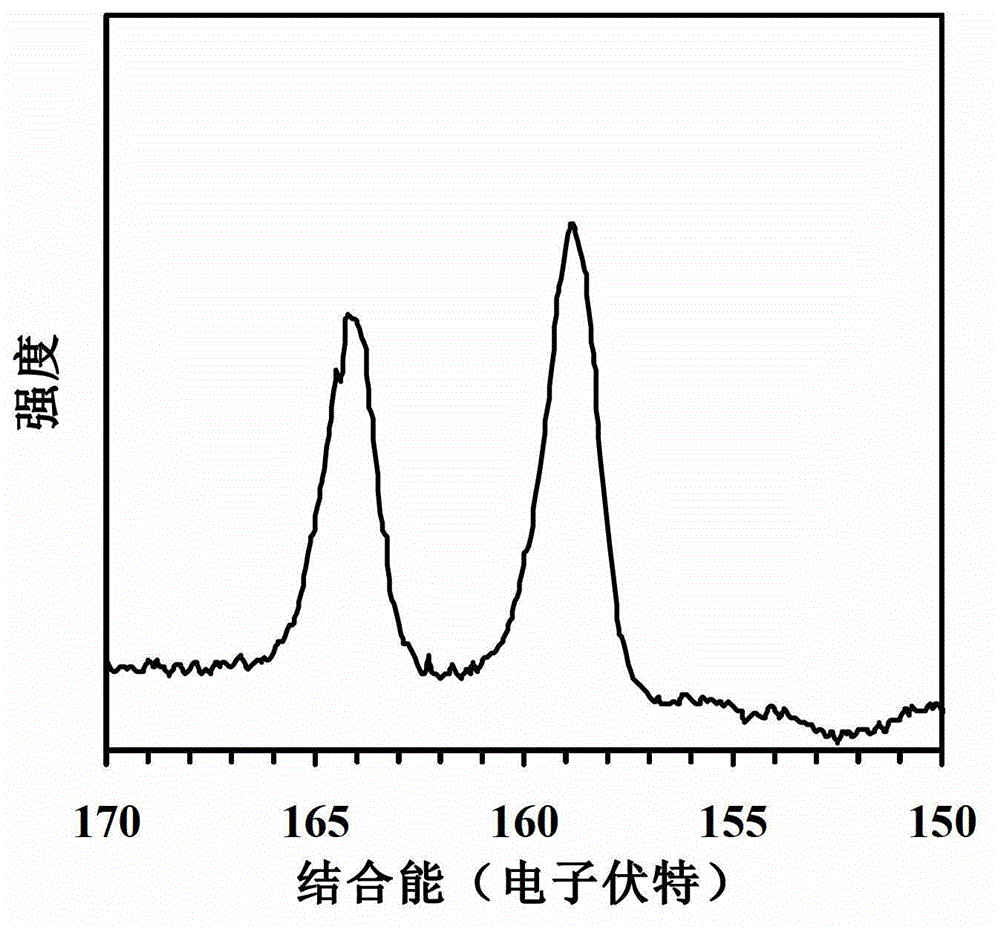

[0026] According to the molar ratio of bismuth nitrate pentahydrate: thiourea: lysine: ethylene glycol in the reaction mixture as 1:1.5:0.25:125, weigh 4.85 g of bismuth nitrate pentahydrate, 1.14 g of thiourea and 0.36 g of lysine Dissolve in 72 ml of ethylene glycol. After stirring to dissolve, add the ethylene glycol solution of thiourea and lysine to the ethylene glycol solution of bismuth nitrate pentahydrate and lysine, and then transfer to 100 ml of crystallization reaction The kettle was heated and crystallized at 160°C for 12 hours. Filter, wash and dry to obtain black powder according to conventional methods. The yellow powder was characterized by X-ray powder diffractometer, scanning electron microscope, etc., and the product was hedgehog bismuth sulfide microspheres.

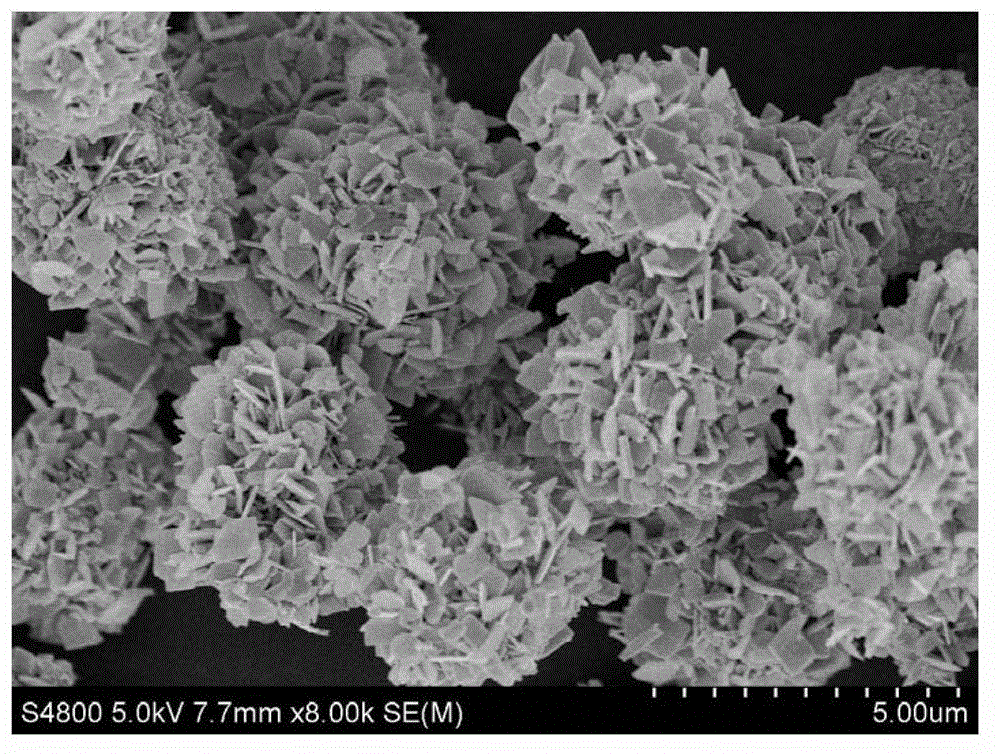

[0027] Weigh 1 gram of the hedgehog-shaped bismuth sulfide and disperse it in 40 ml of a potassium hydroxide aqueous solution with pH=8, then transfer the mixed solution to a crystallization reactor an...

Embodiment 2

[0031] According to the molar ratio of bismuth nitrate pentahydrate: mixed sulfur source (sodium sulfide and thiourea): lysine: ethylene glycol in the reaction mixture is 1:1.5:0.25:125, weigh 4.85 g of bismuth nitrate pentahydrate, a certain amount Sulfur source and 0.36 g of lysine were dissolved in 72 ml of ethylene glycol. After stirring to dissolve, the ethylene glycol solution of thiourea and lysine was added dropwise to the ethylene glycol solution of bismuth nitrate pentahydrate and lysine. Then transfer to a 100 ml crystallization reactor and crystallize at 160°C for 12 hours. Filter, wash, and dry according to conventional methods to obtain yellow powder. The black powder was characterized by X-ray powder diffractometer, scanning electron microscope, etc., and the product was hedgehog bismuth sulfide microspheres.

[0032] Weigh 1 g of the hedgehog-shaped bismuth sulfide and disperse it in 40 ml of a potassium hydroxide aqueous solution with pH=8, then transfer the mix...

Embodiment 3

[0035] According to the molar ratio of bismuth nitrate pentahydrate: mixed sulfur source (sodium sulfide and thiourea): lysine: ethylene glycol in the reaction mixture is 1:1.2:0.25:80, weigh 4.85 g of bismuth nitrate pentahydrate, a certain amount Sulfur source and 0.36 g of lysine are dissolved in 45 ml of ethylene glycol. After stirring to dissolve, the ethylene glycol solution of thiourea and lysine is added dropwise to the ethylene glycol solution of bismuth nitrate pentahydrate and lysine. Then transfer to a 100 ml crystallization reactor and crystallize at 160°C for 12 hours. Filter, wash, and dry according to conventional methods to obtain yellow powder. The black powder was characterized by X-ray powder diffractometer, scanning electron microscope, etc., and the product was hedgehog bismuth sulfide microspheres.

[0036] Weigh 1 g of the hedgehog-shaped bismuth sulfide and disperse it in 40 ml of a potassium hydroxide aqueous solution with pH=8, then transfer the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com