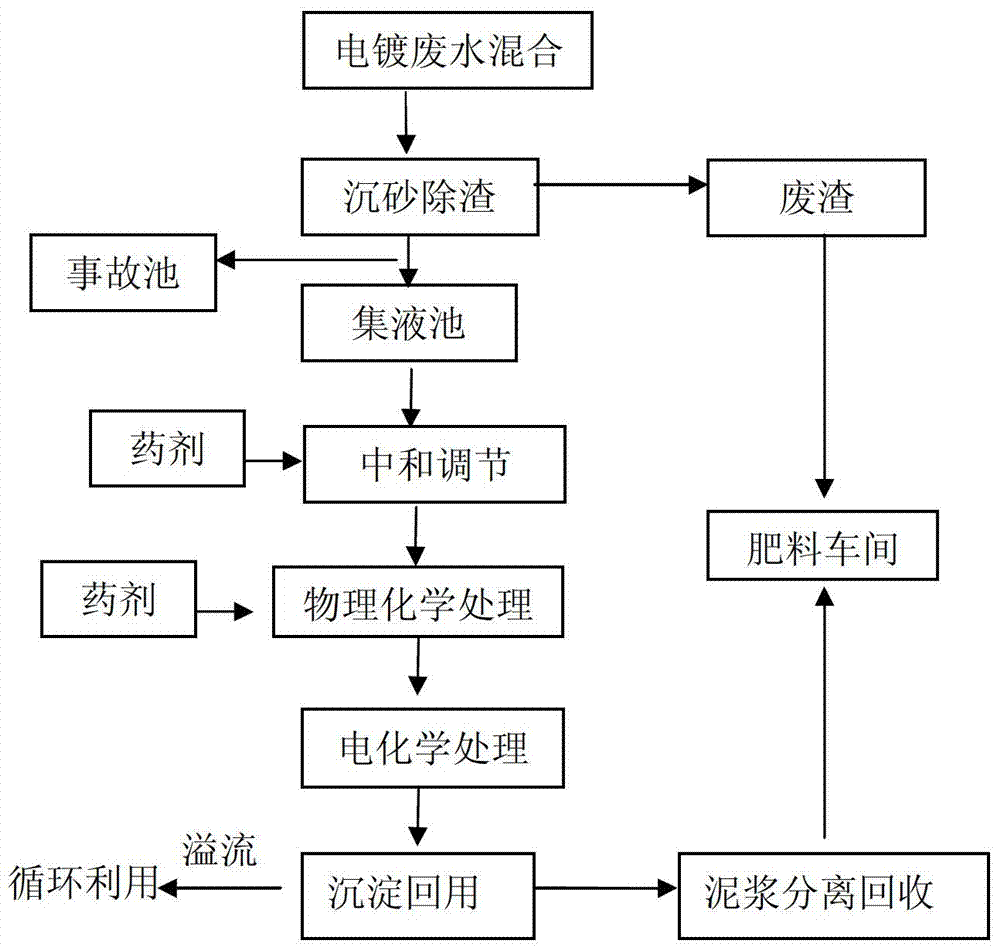

Electroplating wastewater electrochemical treatment and recycling comprehensive method

A technology of electroplating wastewater and comprehensive methods, which is applied in the direction of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of failing to meet the discharge standards of electroplating pollutants, and achieve saving land occupation and less chemical dosage , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The YHD special flocculant used in this example is alum; the neutralizing agent is a mixture of sodium carbonate and sodium sulfate according to the mass ratio = 1:1; the physicochemical agent is a mixture of sodium hypochlorite and sodium pyrosulfite according to the mass ratio = 1:1. The electroplating wastewater is the mixed wastewater of pre-treatment wastewater, cyanide-containing wastewater, chromium-containing wastewater, comprehensive wastewater and mixed wastewater of a large electroplating factory in Guangxi.

[0037] (a) Wastewater mixed treatment: The electroplating wastewater is collected and collected, and then enters the liquid collection pool through the grid machine to obtain the mixed wastewater raw water.

[0038] (b) Grit and slag removal: collect the mixed wastewater raw water obtained in step a), and carry out flocculation reaction for 0.8h with the wastewater and YHD special flocculant according to the ratio of 1T (ton): 50g, remove the grit, f...

Embodiment 2

[0045] The YHD special flocculant used in this example is a mixture of ferric chloride and ferric sulfate according to the mass ratio = 1:1; the neutralizer is sodium hydroxide; the physicochemical agent is sodium sulfate and manganese sulfate according to the mass ratio = 1 :1 mixture. The electroplating wastewater is the mixed wastewater of cyanide-containing wastewater, chromium-containing wastewater and comprehensive wastewater of a large-scale electroplating industrial park sewage treatment plant in Zhongshan City, Guangdong Province.

[0046] (a) Wastewater mixed treatment: The electroplating wastewater is collected and collected, and then enters the liquid collection pool through the grid machine to obtain the mixed wastewater raw water.

[0047] (b) Grit and slag removal: collect the mixed wastewater raw water obtained in step a), and carry out flocculation reaction for 1.0h with the wastewater and YHD special flocculant according to the ratio of 1T:35g, remove the gri...

Embodiment 3

[0054] The YHD special flocculant used in this example is a mixture of alum and polyaluminum chloride according to the mass ratio = 1:1; the neutralizer is potassium hydroxide; the physicochemical agent is sodium hypochlorite and manganese sulfate according to the mass ratio = 1:1 mixture. The electroplating wastewater is the mixed wastewater of pre-treatment wastewater, cyanide-containing wastewater, chromium-containing wastewater, comprehensive wastewater and mixed wastewater of a large-scale electroplating industrial park sewage treatment plant in Zhongshan City, Guangdong Province.

[0055] (a) Wastewater mixed treatment: The electroplating wastewater is collected and collected, and then enters the liquid collection pool through the grid machine to obtain the mixed wastewater raw water.

[0056] (b) Grit and slag removal: collect the mixed wastewater raw water obtained in step a), and carry out flocculation reaction with YHD special flocculant according to the ratio of 1T:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com