Process for producing medical dried yeast powder

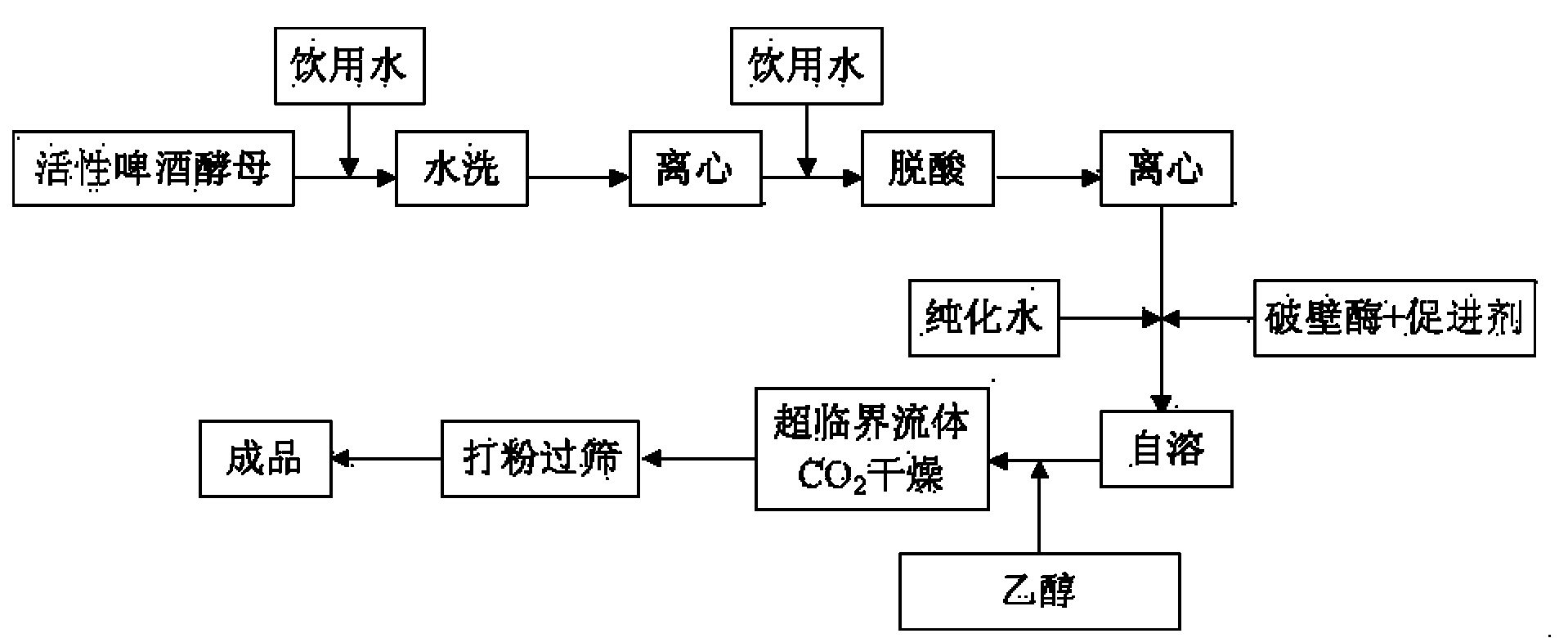

A production process and technology of dry yeast powder, which is applied in powder transportation, drug combination, pharmaceutical formula, etc., can solve the problems of dry yeast powder nutrient element destruction and long production cycle, so as to promote yeast autolysis, reduce drying temperature, reduce Effect of autolysis temperature and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 100.0 kg of active brewer's yeast into 300 kg of drinking water, stir and wash for 30 minutes, then centrifuge and dehydrate, disperse the filter cake in 200 kg of drinking water, add NaOH to adjust the pH to 8.5, centrifuge and wash to neutral, and the obtained 95 Disperse kg of filter cake in 95 kg of purified water, add 0.5 kg of lysozyme, 0.3 kg of mannitolase, and 2.0 kg of a mixture of sodium lauryl sulfate and potassium bicarbonate, heat up to 45°C, react for 6 h, and then add ethanol 10.0 kg, after stirring for 30 minutes, put the colloid solution into the supercritical reactor, control the pressure of the reactor to 10 MPa, the temperature is 50 °C, and the gaseous CO containing solvent 2 The flow rate was 20 L / min. After drying for 2 hours, the obtained material was powdered and passed through a 50-mesh sieve to obtain 56.4 kg of finished product, with a yield of 56.4%. The obtained product has a water content of 1.5% and a protein content of 54%.

Embodiment 2

[0028] Put 100.4 kg of active brewer's yeast into 300 kg of drinking water, stir and wash for 30 minutes, then centrifuge and dehydrate, disperse the filter cake in 200 kg of drinking water, add NaOH to adjust the pH to 8.5, centrifuge and wash to neutral, and the obtained 92 kg Disperse the filter cake in 92 kg of purified water, add 0.4 kg of helicase, 0.4 kg of mannitolase, 2.0 kg of a mixture of sodium lauryl sulfate and potassium bicarbonate, raise the temperature to 50°C, and react for 6 h, then add 10.0 kg of ethanol kg, after stirring for 30 minutes, put the colloidal solution into the supercritical reactor, control the pressure of the reactor to 10 MPa, the temperature to 50°C, and the solvent-containing gaseous CO 2 The flow rate was 20 L / min. After drying for 2 hours, the obtained material was powdered and passed through a 50-mesh sieve to obtain 53.7 kg of finished product, with a yield of 53.5%. The obtained product has a water content of 1.8% and a protein conten...

Embodiment 3

[0030] Put 500.0 kg of active brewer's yeast into 1,500 kg of drinking water, stir and wash for 30 minutes, then centrifugally dehydrate, disperse the filter cake in 1,000 kg of drinking water, add NaOH to adjust the pH to 8.0, and wash with centrifugal water until neutral, and the obtained 465 Disperse kg of filter cake in 465 kg of purified water, add 5 kg of β-1,3-glucanase, 1.5 kg of mannosidase, 10 kg of a mixture of sodium lauryl sulfate and potassium bicarbonate, heat up to 50°C, and react After 7 h, 60.0 kg of ethanol was added, stirred for 30 minutes, and the colloidal solution was poured into a supercritical reactor. The pressure of the reactor was controlled at 12 MPa and the temperature was 50 °C. 2 The flow rate was 50 L / min. After drying for 2.5 hours, the obtained material was powdered and passed through a 50-mesh sieve to obtain 276.0 kg of finished product, with a yield of 55.2%. The obtained product has a water content of 1.8% and a protein content of 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com