Biological slime inhibitor and preparation method thereof

A biological slime and inhibitor technology, applied in botany equipment and methods, biocides, chemicals for biological control, etc., can solve the problems of poor compatibility of corrosion and scale inhibitors and dispersants, and low bactericidal efficiency High, few types of organic guanidine products, etc., to achieve excellent algicidal performance, excellent killing inhibition effect, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 polydihexamethylene triamine guanidine hydrochloride product

[0041] Preparation of poly(dihexamethylenetriamine) guanidine hydrochloride product: Add 215g (1.0mol) of dihexamethylenetriamine and guanidine hydrochloride respectively into a 1000ml four-neck flask equipped with mechanical stirring, reflux condenser, thermometer and ammonia absorption device 95.5g (1.0mol), 200g ethylene glycol, heated to 80°C, reacted for 4h; then raised the temperature to 180°C, continued to react for 2h. Then add 80 g of water, stir evenly, and cool to room temperature to obtain a poly(dihexamethylenetriamine) guanidine hydrochloride product with a solid content of 50%, coded as "Product A".

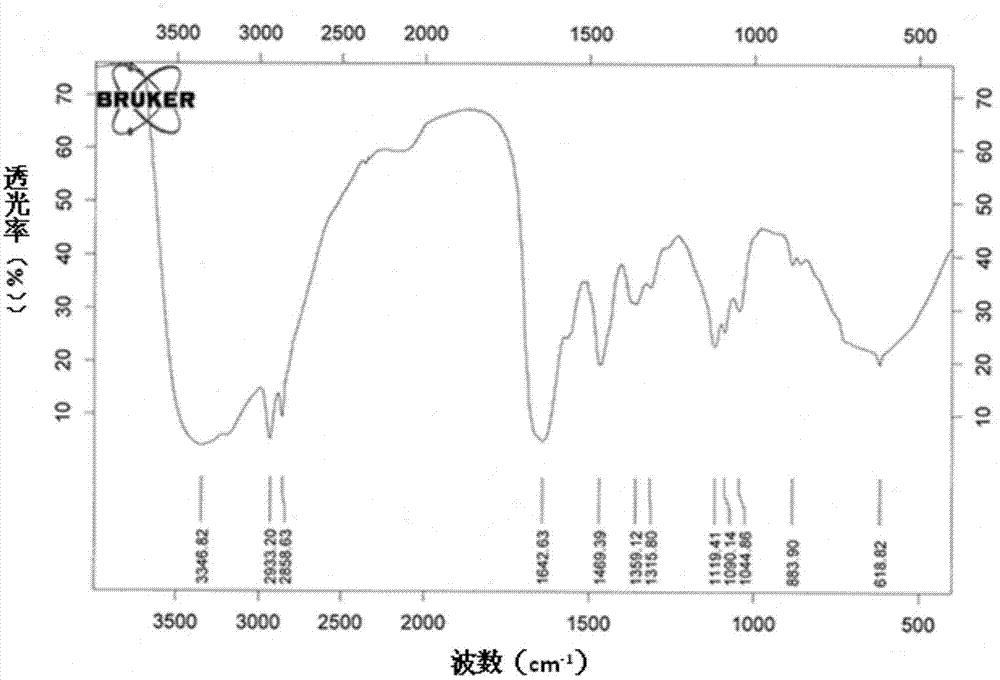

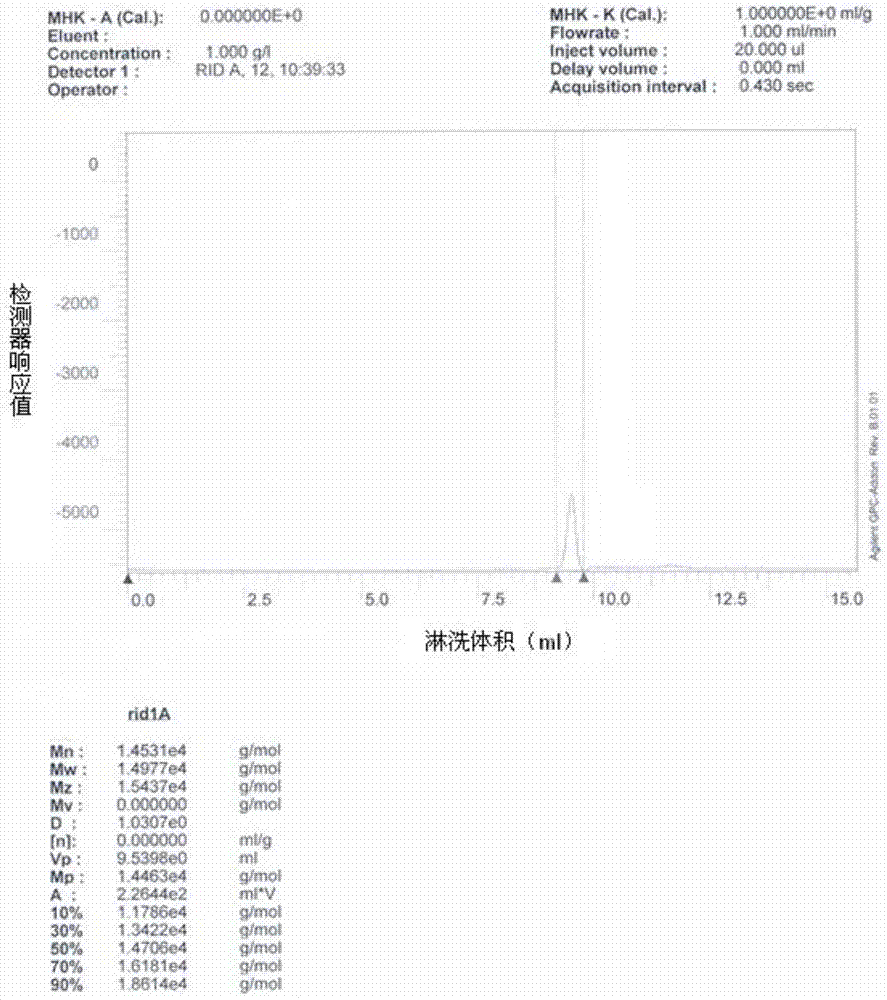

[0042] From its infrared spectrum (attached figure 1 ) analysis shows: 3346.82cm -1 and 3195.44cm -1 It is the out-of-plane deformation vibration absorption peak of N-H bond; 1642.63cm -1 It is the stretching vibration absorption peak of C=N in the guanidine gr...

Embodiment 2

[0043] The preparation of embodiment 2 biological slime inhibitors

[0044] Add poly(dihexamethylenetriamine) guanidine hydrochloride product and water to the reaction bottle in turn, after stirring well, adjust the pH value to below 6 with hydrochloric acid, add solvent, after stirring evenly, then add isothiazolinone and organic bromide, continue After stirring until completely dissolved, the biological slime inhibitor of the present invention is obtained. Using this preparation method, prepare biological slime inhibitor products N1-N6 with different components and component ratios (mass percentage) shown in Table 1:

[0045] Table 1 Composition of biological slime inhibitor products

[0046]

[0047] Note: CIT / MIT——isothiazolinone, 14% industrial product; DBNPA——2,2-dibromo-3-nitropropionamide; DBNE——2,2-dibromo-2-nitroethanol ; BNPD——bronopol; DBNPA, DBNE, and BNPD are all industrial products with a purity of ≥99%.

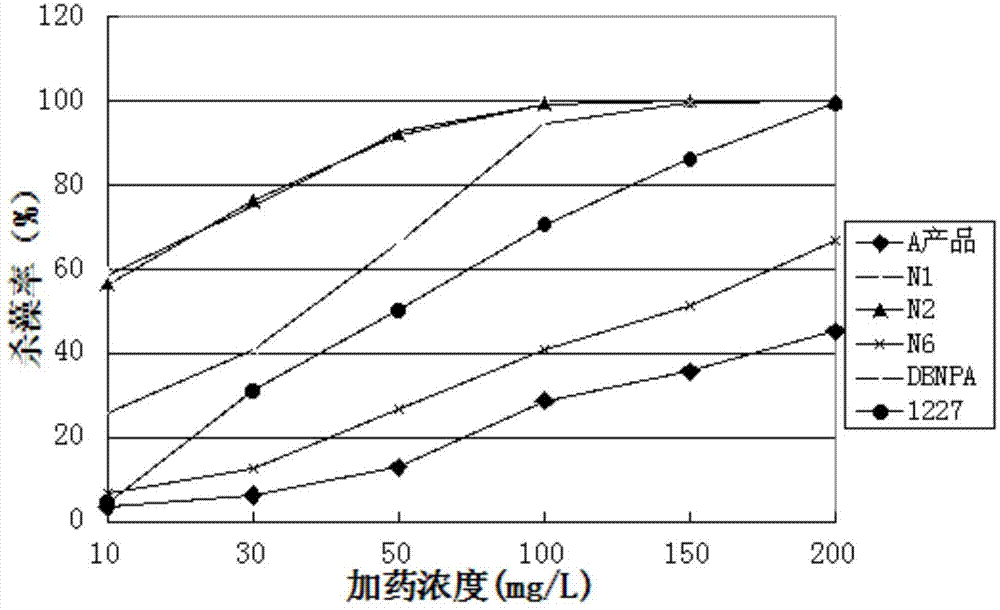

[0048] Embodiment 3 bactericidal performance evalu...

Embodiment 5

[0060] Embodiment 5 compatibility evaluation

[0061] Compatibility tests were carried out between the product of the present invention and common industrial circulating cooling water corrosion inhibitors and scale inhibitors and dispersants to investigate their mutual influence. The evaluation method of scale inhibition performance is "Calcium Carbonate Deposition Method for Determination of Scale Inhibition Performance of Water Treatment Agents" (GB / T16632-2008), and the evaluation method of corrosion inhibition performance is "Determination of Corrosion Inhibition Performance of Water Treatment Agents Rotating Coupon Method" ( GB / T18175-2000), the bactericidal performance evaluation method is the same as that used in Example 3. Evaluation adopts medicament description as follows: N4---the N4 fungicide in the embodiment of the present invention 3; HS-1---organophosphorus corrosion inhibitor, is 2-phosphonic acid butane 1,2,4-tricarboxylic acid (PBTC ) and zinc chloride; ATM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com