Method for preparing nitrogen and phosphorus codoped porous graphene material

A porous graphene, co-doping technology, applied in directions such as graphite, can solve the problems of toxic etchants, difficult industrial production, application limitations, etc., and achieve the effects of convenient method, large specific surface area and large pore volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

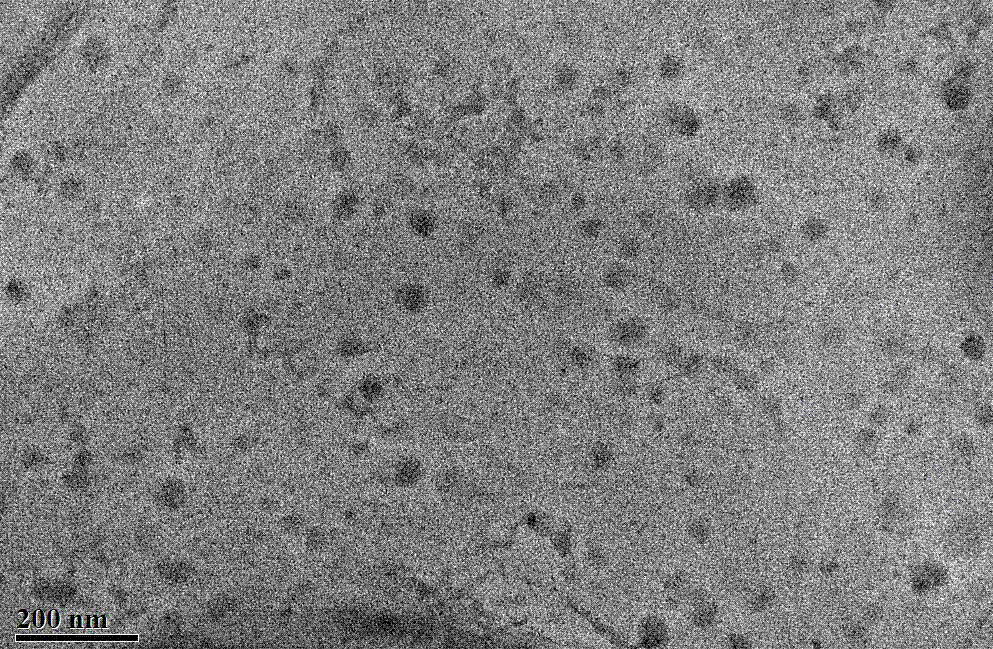

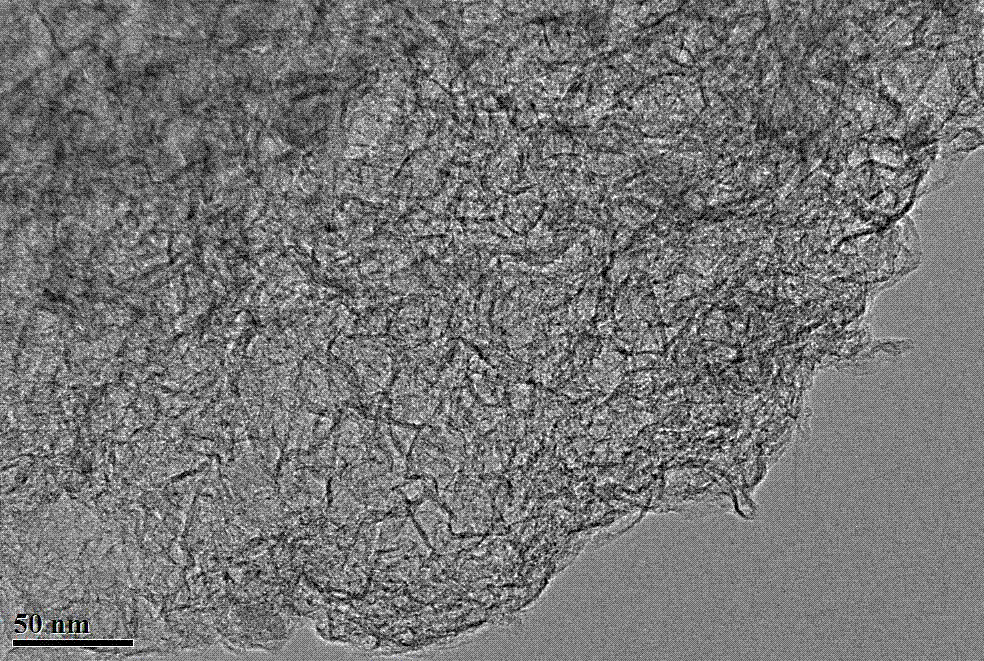

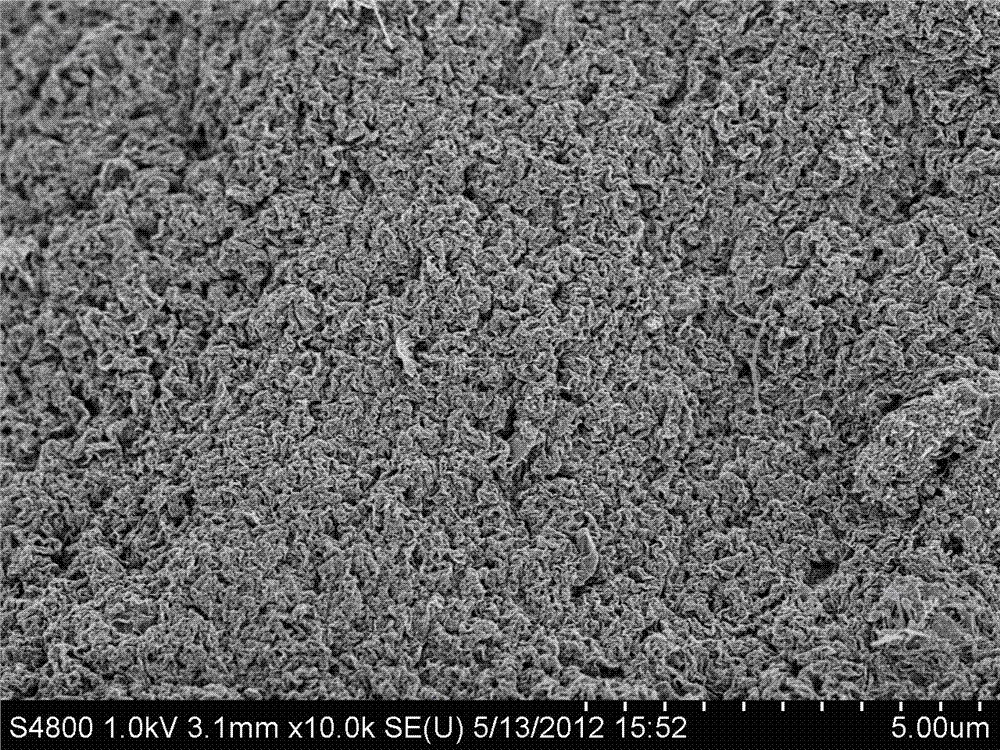

[0023] Embodiment 1. The preparation of a kind of nitrogen-phosphorus co-doped porous graphene

[0024] (1) Add 16.8 g of 4-vinylbenzyl chloride, 29.8 g of triphenylphosphine and 100 mL of acetone into a dry flask equipped with a magnetic stirring device, and react in a water bath at 45 °C under a nitrogen atmosphere for 10 hours, then filtered, washed with acetone and dried in a vacuum oven for 12 h;

[0025] (2) Add 4.148 g of PIL monomer obtained in step (1), 6 g of allyl glycidyl ether, and 0.08 g of azobisisobutyronitrile to 260 mL of methanol solution, and react at 70 °C After 6 h, it was added to a large amount of ether solution. The precipitated product was filtered, washed three times with tetrahydrofuran and deionized water, and then dried in vacuum for 12 h;

[0026] (3) Add 32 mg of PPIL and 64 mg of graphene oxide obtained in step (2) into 80 mL of water, disperse evenly by ultrasonication, add 5 mL of ammonia solution, and react at 180 °C for 12 h. After cooli...

Embodiment 2

[0027] Embodiment 2. Preparation of a nitrogen-phosphorus co-doped porous graphene

[0028] (1) Add 33.6 g of 4-vinylbenzyl chloride, 59.6 g of triphenylphosphine and 200 mL of acetone into a dry flask equipped with a magnetic stirring device, and react in a water bath at 45 °C under a nitrogen atmosphere for 10 hours, then filtered, washed with acetone and dried in a vacuum oven for 12 h;

[0029] (2) Add 8.296 g of PIL monomer obtained in step (1), 12 g of allyl glycidyl ether, and 0.16 g of azobisisobutyronitrile to 260 mL of methanol solution, and react at 70 °C After 6 h, it was added to a large amount of ether solution. The precipitated product was filtered, washed three times with tetrahydrofuran and deionized water, and then dried in vacuum for 12 h;

[0030] (3) Add 64 mg of PPIL and 128 mg of graphene oxide obtained in step (2) into 160 mL of water, disperse evenly by ultrasonic, add 10 mL of ammonia solution and react at 180 °C for 12 h. After cooling to room tem...

Embodiment 3

[0031] Embodiment 3. Preparation of a nitrogen-phosphorus co-doped porous graphene

[0032] (1) Add 84 g of 4-vinylbenzyl chloride, 149 g of triphenylphosphine and 500 mL of acetone into a dry flask equipped with a magnetic stirring device, and react in a water bath at 45 °C under a nitrogen atmosphere for 10 hours, then filtered, washed with acetone and dried in a vacuum oven for 12 h;

[0033](2) Add 20.744 g of PIL monomer obtained in step (1), 30 g of allyl glycidyl ether, and 0.4 g of azobisisobutyronitrile to 1300 mL of methanol solution, and react at 70 °C After 6 h, it was added to a large amount of ether solution. The precipitated product was filtered, washed three times with tetrahydrofuran and deionized water, and then dried in vacuum for 12 h;

[0034] (3) Add 512 mg of PPIL and 320 mg of graphene oxide obtained in step (2) into 160 mL of water, disperse evenly by ultrasonic, add 10 mL of ammonia solution, and react at 180 °C for 12 h. After cooling to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com