Method for treating sewage by using anaerobic membrane bioreactor to remove sulphur and nitrogen

An anaerobic reactor and anaerobic membrane biological technology, applied in the field of sewage treatment, can solve the problems of poor system impact resistance, low sludge concentration, long acclimation time, etc., and achieve increased stability, impact resistance, and energy consumption level. The effect of reduction and footprint reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

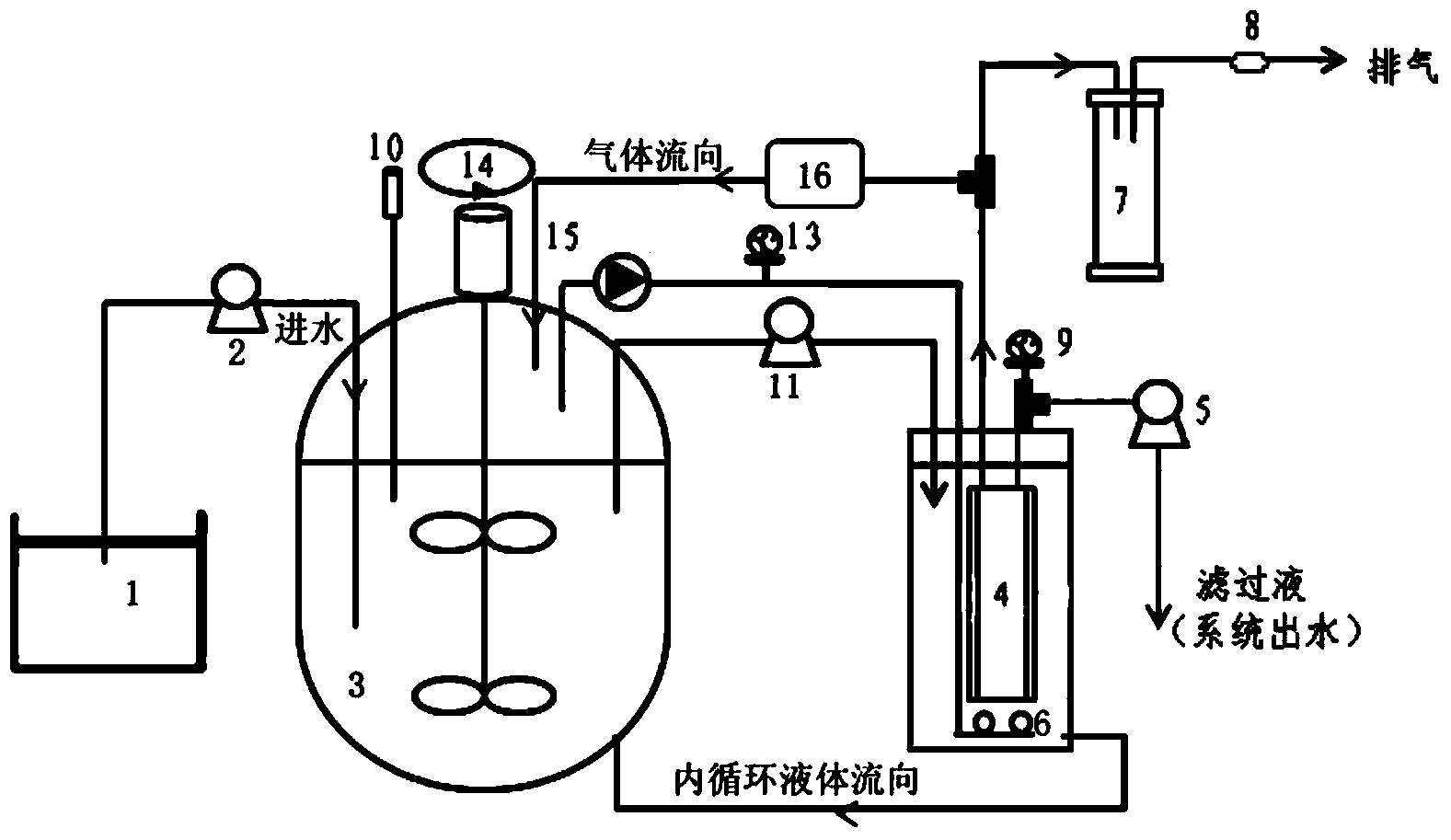

[0071] Embodiment 1, external type internal circulation aerated anaerobic membrane bioreactor

[0072] Such as image 3 As shown, it is a schematic structural diagram of a preferred embodiment of the sewage treatment equipment of the present invention. The sewage treatment equipment of the present embodiment comprises:

[0073] Water inlet tank 1, water inlet pump 2, anaerobic reactor 3, membrane module 4 and its supporting equipment (such as closed membrane tank 4-1), outlet pump 5, distributor 6, gas storage tank 7, pressure valve 8, span Membrane differential pressure probe 9, sensor 10, circulation pump 11, gas flow meter 13, agitator 14, gas circulation pump 15, absorption tower 16.

[0074] Wherein, the sewage in the water inlet pool 1 is pumped into the anaerobic reactor 3 by the water inlet pump 2, and the upper air-gathering space of the anaerobic reactor 3 communicates with the distributor 6 arranged under the membrane module 4 through an air supply pipeline. A ga...

Embodiment 2

[0085] Embodiment 2, built-in internal circulation aerated anaerobic membrane bioreactor

[0086] Such as Figure 4 As shown, in this embodiment, the sewage treatment equipment adopts a built-in membrane module internal circulation aerated anaerobic membrane bioreactor, wherein the membrane module 4 is arranged inside the anaerobic reactor 3, that is, a built-in membrane module is used. Corresponding to this feature, there is no need to set the liquid internal circulation passage in Embodiment 1 in this embodiment, and the gas internal circulation passage only needs to be provided with a gas supply pipeline connecting the anaerobic reactor and the distributor below the membrane module. Yes, without setting the return air line in Embodiment 1.

[0087] In addition to the advantages described in Example 1, this example, due to the design of its built-in membrane module, enables the internal circulation aeration to simultaneously achieve effective membrane cleaning, water inflow...

Embodiment 3

[0090] Embodiment 3, external type internal circulation jet aeration anaerobic membrane bioreactor

[0091] Such as Figure 5 As shown, the sewage treatment equipment of this embodiment adopts an anaerobic membrane bioreactor with external membrane modules and internal circulation jet aeration, wherein the sewage in the inlet pool 1 is pumped into the anaerobic reactor 3 by the inlet pump 2, and the anaerobic reaction The upper gas-gathering space of the device 3 communicates with the gas-liquid mixed flow distributor 6 located below the membrane module 4 through a jet aeration pipeline. In this embodiment, the delivery of nitrogen is realized by jet flow. The airtight The air outlet on the upper part of the membrane pool 4-1 communicates with the upper gas collection space of the anaerobic reactor 3 through a gas return pipeline, and an absorption tower 16 is arranged on the gas return pipeline.

[0092] Specifically, the solid-liquid mixture in the anaerobic reactor 3 is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com