Room-temperature-curing acrylic heteropolysiloxane nano-ceramic protection coating and preparation method thereof

A technology of heteropolysiloxane and nano-ceramics, which is applied in the direction of coating, etc., can solve the problems of micropores, reduce crosslinking density, and easy cracks, etc., and achieve high hardness of coating film, uniform film formation, and stain resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of acrylic silicone wax

[0037] Into a 250ml three-necked flask equipped with a reflux device, 100g of liquid low-hydrogen polymethylhydrogensiloxane (also known as low-hydrogen silicone oil, active hydrogen content (Si-H) is 0.36wt%), 60.5 1 g of 1-octadecene, stir, add 1.5 g of platinum divinyltetramethyldisiloxane double head complex solution (Karsted catalyst) (the concentration of platinum is 1500ppm), and heat to 120°C for reaction After 3 hours, cool to 90° C., slowly add 8.6 g of acrylic acid (AA) dropwise, and keep the reaction for 3 hours. Then cooled to room temperature to obtain acrylic silicone wax polymer SA1. Infrared spectroscopy experiments show that the silicone wax synthesized by the hydrosilylation reaction does not contain Si-H bonds, but contains carboxyl and propionic acid groups (-CH 2 CH 2 COOH) content is 5.1wt%.

[0038] In a 250ml three-necked flask equipped with a reflux device, add 100g of low-hydrogen sil...

Embodiment 2

[0041] (1) Coating preparation

[0042] First, 4g of acrylic silicone wax SA1 and 0.2g of phenylboronic acid (PhB(OH) 2 ) and 10g of diluent propylene glycol monomethyl ether were mixed evenly, and slowly added to 20g of silica sol S2 (Grace Ludox CL-P, 40wt% water sol, pH=4, average particle size of 22nm) system under stirring, and the modified Reactive silica sol SS2. Divide SS2 into two halves, one half is used to observe the storage stability at room temperature, and the other half is slowly added a mixed solution of 10g methyltrimethoxysilane (MTMS) and 0.5g silane coupling agent KH560 under stirring, and continues to stir at room temperature After 2 hours, it is coated on the surface of the substrate and dried naturally to form a high-hardness high-temperature-resistant ceramic protective coating. The paint formulations are listed in Table 1.

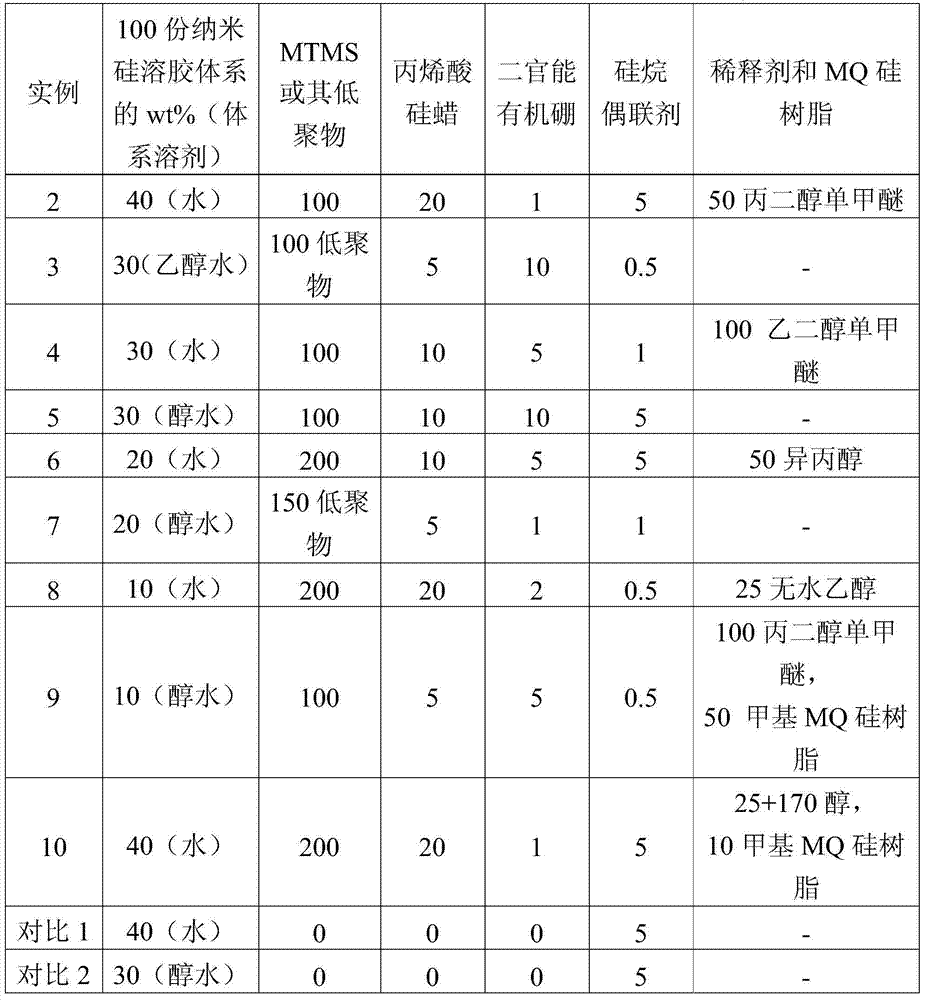

[0043] Table 1: Example formula table (the unit is the number of parts, each corresponding to 0.1g)

[0044]

[0045] (2)...

example 2

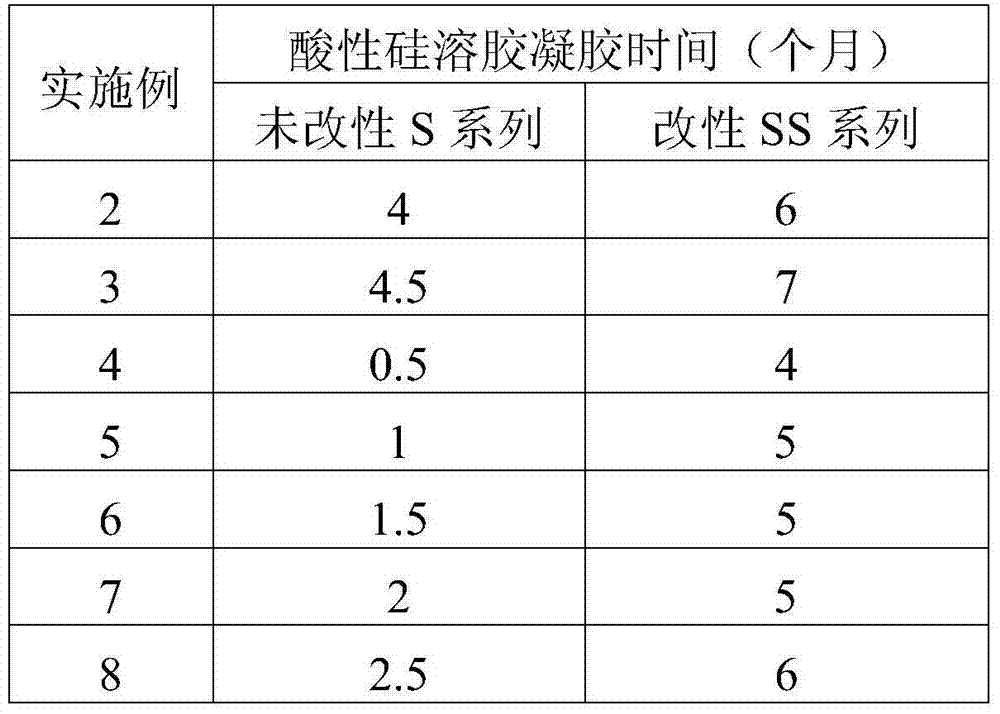

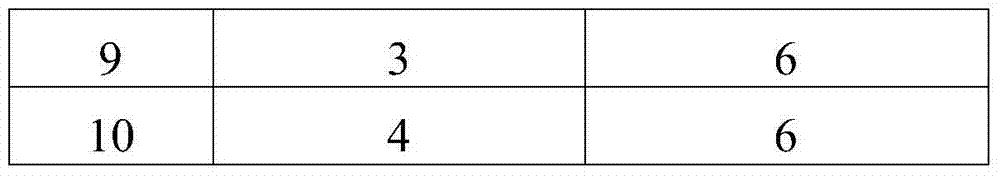

[0051] The coatings configured in Example 2 were tested for their respective performances according to the above methods, and the results are listed in Table 3.

[0052] The storage stability experiment preliminarily shows that the gel time of the modified acidic silica sol of the present invention can be extended by 2 months.

[0053] The experimental results of the performance test show that the coating prepared by the present invention has excellent film-forming properties, is not easy to crack and pulverize, has excellent water resistance, and has excellent stain resistance (the lower the reflection coefficient decline rate, the higher the stain resistance it is good).

[0054] The results of accelerated curing of the coating film show that the coating film is cured at room temperature for 4 hours and then cured in an oven at 200°C for 2 hours, and the measured hardness is the same as that cured at room temperature for 3 days. Proper heat treatment can significantly speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com