A kind of phosphorus-free, hexavalent chromium-free environment-friendly plastic electroplating method

A technology of plastic electroplating and hexavalent chromium, which is applied in the field of plastic electroplating, can solve the problems of many transition bins of devices, unable to lock valves, low utilization rate, etc., and achieves convenient equipment maintenance, convenient maintenance and replacement, and high effective utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

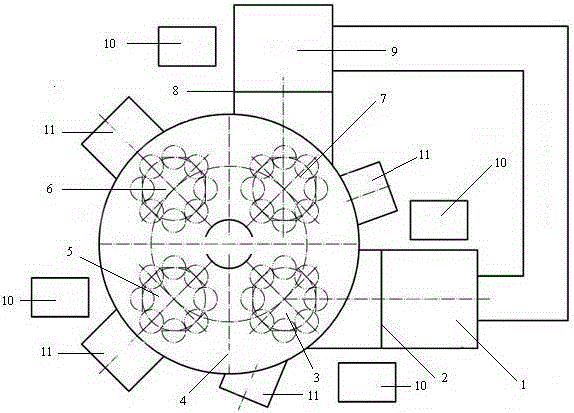

Method used

Image

Examples

Embodiment 1

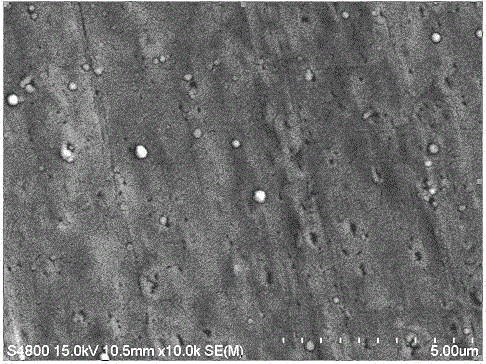

[0046] Example 1 Implementation of phosphorus-free, hexavalent chromium-free environmentally friendly plastic electroplating process on ABS (acrylonitrile, butadiene and styrene polymer) engineering plastic multifunctional shower shell

[0047] Specific steps are as follows:

[0048] 1) Put the PVD hanger on the ABS shower head injection molded blank, after cleaning the surface, dry it at 70°C for 3 hours;

[0049] 2) After drying, the hanger is transferred to the turntable, and the outer rail car pushes into the feeding bin, draws a low vacuum and starts the low-temperature water vapor trap to complete the pre-vacuum process.

[0050] 3) The first flapper valve is opened, and the turret is pushed into the No. 1 station of the vacuum chamber by the pneumatic manipulator.

[0051] 4) The No. 1 station performs low-temperature plasma surface modification at 30°C. The process conditions are ion source current: 0.3A, bias voltage: 200V, duty cycle: 50%, argon flow rate: 50SCCM, a...

Embodiment 2

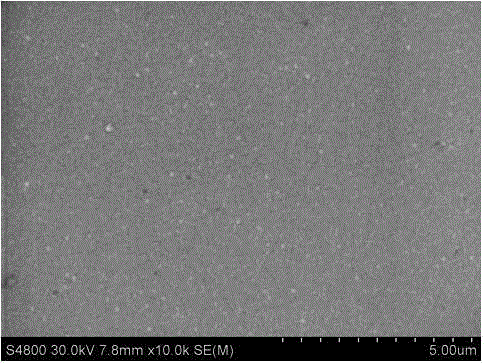

[0059] Example 2Abs+PC (polycarbonate) micro-boiler handle implements phosphorus-free, hexavalent chromium-free environmentally friendly plastic electroplating process

[0060] Specific steps are as follows:

[0061] 1) Put the PVD hanger on the injection molding blank of the handle of the micro-boiler, after cleaning the surface, dry it at 80°C for 2 hours;

[0062] 2) After drying, the hanger is transferred to the turntable, and the outer rail car pushes into the feeding bin, draws a low vacuum and starts the low-temperature water vapor trap to complete the pre-vacuum process.

[0063] 3) The first flapper valve is opened, and the turret is pushed into the No. 1 station of the vacuum chamber by the pneumatic manipulator.

[0064] 4) No. 1 station is used for low-temperature plasma surface modification, and the process conditions are ion source current: 0.5A, bias voltage: 300V, duty cycle: 75%, argon flow rate: 150SCCM, oxygen flow rate: 100SCCM, vacuum in the furnace Pres...

Embodiment 3

[0072] Example 3 The bathroom faucet shell made of PA (polyamide) + mineral powder implements a phosphorus-free and hexavalent chromium-free environmentally friendly plastic electroplating process

[0073] Specific steps are as follows:

[0074] 1) Put the PA + mineral powder bathroom faucet shell molding blank on the PVD hanger, after cleaning the surface, dry it at 120°C for 1 hour;

[0075] 2) After drying, the hanger is transferred to the turntable, and the outer rail car pushes into the feeding bin, draws a low vacuum and starts the low-temperature water vapor trap to complete the pre-vacuum process.

[0076] 3) The first flapper valve is opened, and the turret is pushed into the No. 1 station of the vacuum chamber by the pneumatic manipulator.

[0077] 4) The No. 1 station performs glow electrode cleaning. The process conditions are glow electrode voltage: 2500V, duty cycle: 100%, argon flow rate: 75SCCM, nitrogen flow rate: 100SCCM, vacuum pressure in the furnace: 0.7P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com