Preparation method for lithium titanate lithium ion battery

A lithium ion battery, lithium titanate technology, applied in the field of electrochemistry, can solve the problem of lithium titanate being prone to gas swelling, and achieve the effects of improving wettability, improving fast charge-discharging performance and cycle performance, and inhibiting gas swelling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

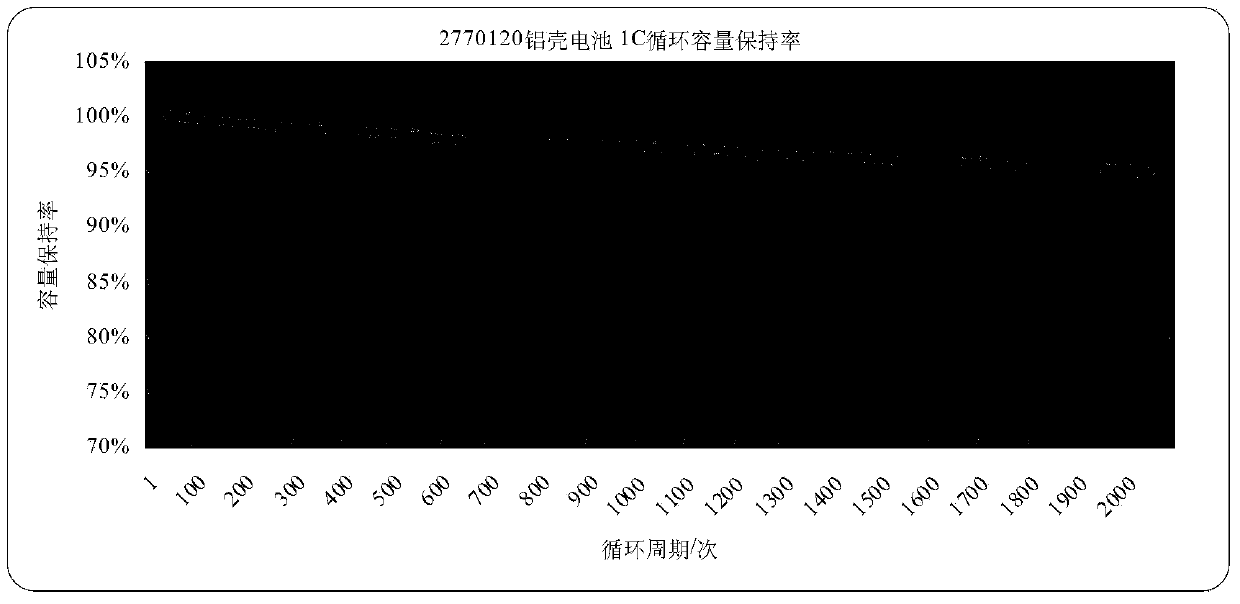

Embodiment 1

[0037] Preparation of the positive electrode sheet: lithium nickel cobalt manganese oxide (LiCo 1 / 3 Ni 1 / 3 mn 1 / 3 o 2 ), conductive carbon black (Super-P), polyvinylidene fluoride (PVDF) are mixed with N,N-dimethylpyrrolidone (NMP) in a certain proportion, and stirred evenly to obtain a slurry for coating the positive electrode sheet. Then, the slurry is evenly coated on the positive electrode current collector (aluminum foil) with a certain width, and the positive electrode sheet is produced by cold pressing and slicing (that is, cutting the positive electrode sheet to a required size).

[0038] Preparation of negative electrode sheet: Lithium titanate (Li 4 Ti 5 o 12 ) is the negative electrode active material, and the binder polyvinylidene fluoride (PVDF), conductive carbon black (Super-P), additive phosphorus flake graphite in a mass ratio of 90:4:5:1, and N,N-dimethyl Pyrrolidone (NMP) was mixed and prepared into negative electrode slurry, and the current collector ...

Embodiment 2

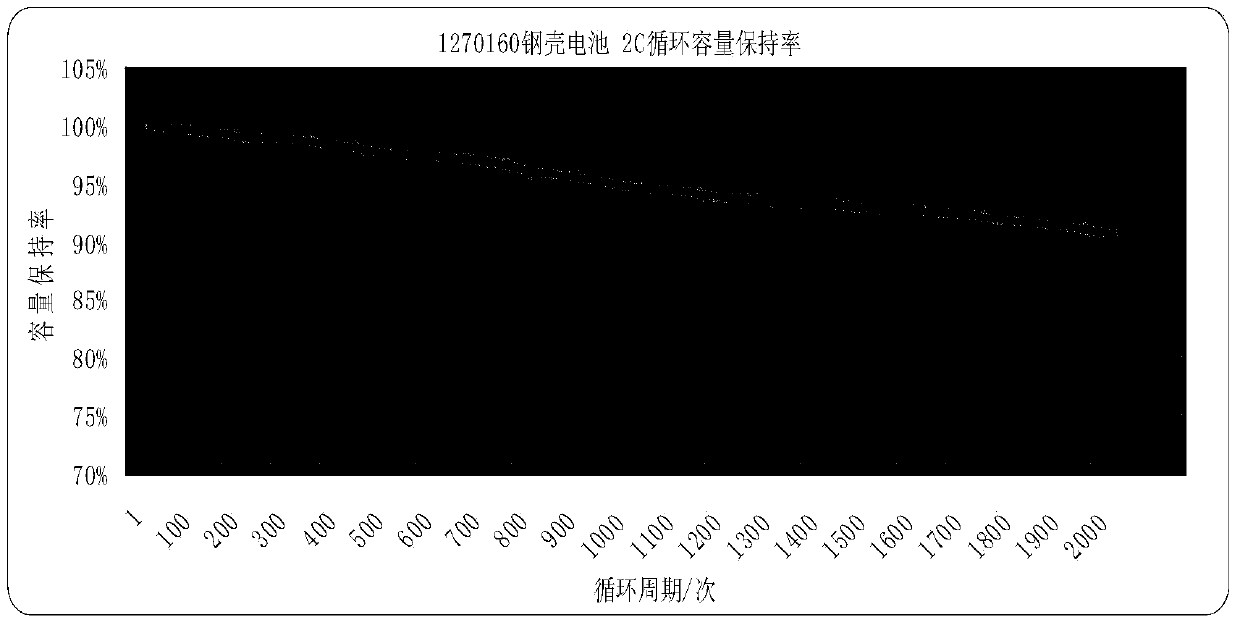

[0048] Preparation of the positive electrode sheet: Lithium manganese oxide (Li 2 MnO 4 ), conductive carbon black (Super-P), polyvinylidene fluoride (PVDF) are mixed with N,N-dimethylpyrrolidone (NMP) in a certain proportion, and stirred evenly to obtain a slurry for coating the positive electrode sheet. Then, the slurry is evenly coated on the positive electrode current collector (aluminum foil) with a certain width, and the positive electrode sheet is produced by cold pressing and slicing (that is, cutting the positive electrode sheet to a required size).

[0049] Preparation of negative electrode sheet: Lithium titanate (Li 4 Ti 5 o 12 ) is the negative electrode active material, and the binder polyvinylidene fluoride (PVDF), conductive carbon black (Super-P), additive phosphorus flake graphite in a mass ratio of 90:5:3:2, and N,N-dimethyl Pyrrolidone (NMP) was mixed and prepared into negative electrode slurry, and the current collector was aluminum foil, which was coa...

Embodiment 3

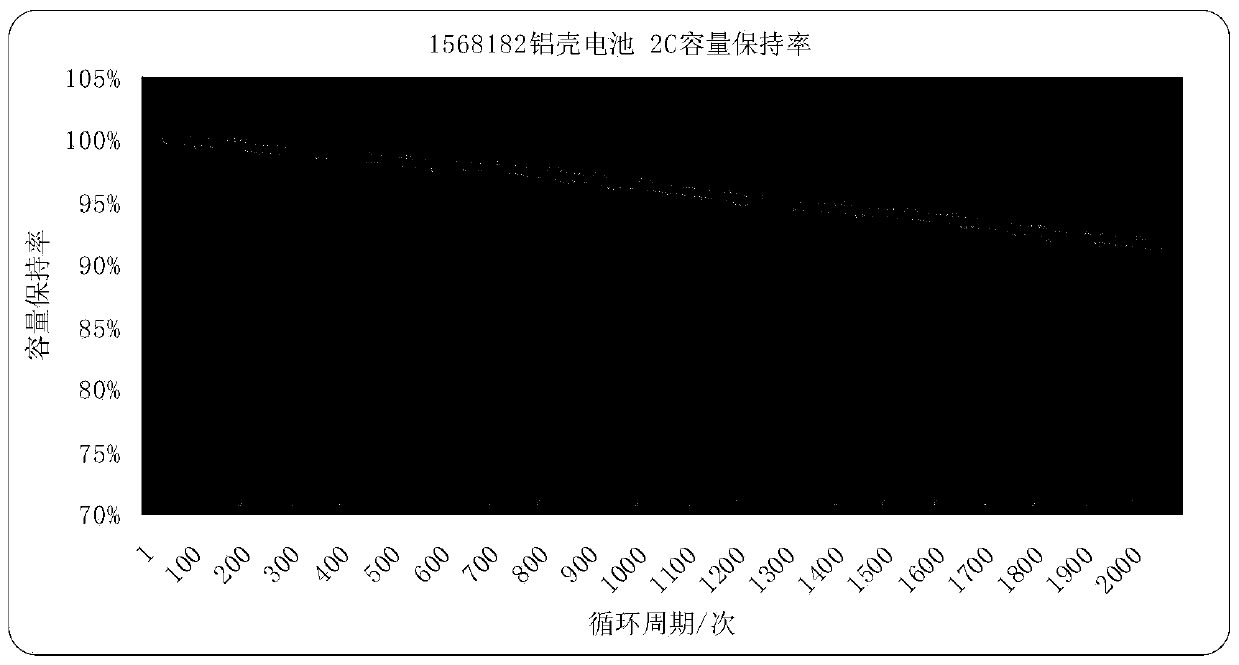

[0059] Preparation of positive electrode sheet: lithium cobalt oxide (LiCoO 2 ), conductive carbon black (Super-P), polyvinylidene fluoride (PVDF) are mixed with N,N-dimethylpyrrolidone (NMP) in a certain proportion, and stirred evenly to obtain a slurry for coating the positive electrode sheet. Then, the slurry is evenly coated on the positive electrode current collector (aluminum foil) with a certain width, and the positive electrode sheet is produced by cold pressing and slicing (that is, cutting the positive electrode sheet to a required size).

[0060] Preparation of negative electrode sheet: Lithium titanate (Li 4 Ti 5 o 12 ) is the negative electrode active material, and the binder polyvinylidene fluoride (PVDF), conductive carbon black (Super-P), additive phosphorus flake graphite in a mass ratio of 90:5:3:2, and N,N-dimethyl Pyrrolidone (NMP) was mixed and prepared into negative electrode slurry, and the current collector was aluminum foil, which was coated accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com