Preparation method of thiol-functionalized magnetic silica nano-material

A technology of silica and nanomaterials, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of limited application and promotion, long reaction cycle, high energy consumption for preparation, and achieve Good selectivity, short reaction time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 8.66g (0.032mol) FeCl respectively 3 ·6H 2 O and 5.56 g (0.002 mol) FeSO 4 ·7H 2 O, dissolved in 100mL deionized water, its molar concentration is higher than that of Fe 3+ : Fe 2+ =1.6:1, add 100mL polyethylene glycol solution, ultrasonically disperse at 25°C, and slowly add ammonia water dropwise under nitrogen protection at a flow rate of 150mL / min to make the reaction system alkaline until the pH is 11. Heating in a water bath at 400 rpm, stirring at a constant temperature for 2 hours, washing with deionized water until neutral, and vacuum drying at 60°C for 10 hours to obtain ferric oxide nanoparticles.

[0031] (2) Weigh 2.0 g of ferric oxide nanoparticles prepared in step (1), ultrasonically disperse them in 50 mL of deionized water at 25 °C, then ultrasonically disperse 1.80 mL of tetraethyl orthosilicate in 80 mL of methanol, and Add 5mL of ammonia water to the above reaction system together, at 25°C, at a stirring speed of 400 rev / min, ultrasoni...

Embodiment 2~12

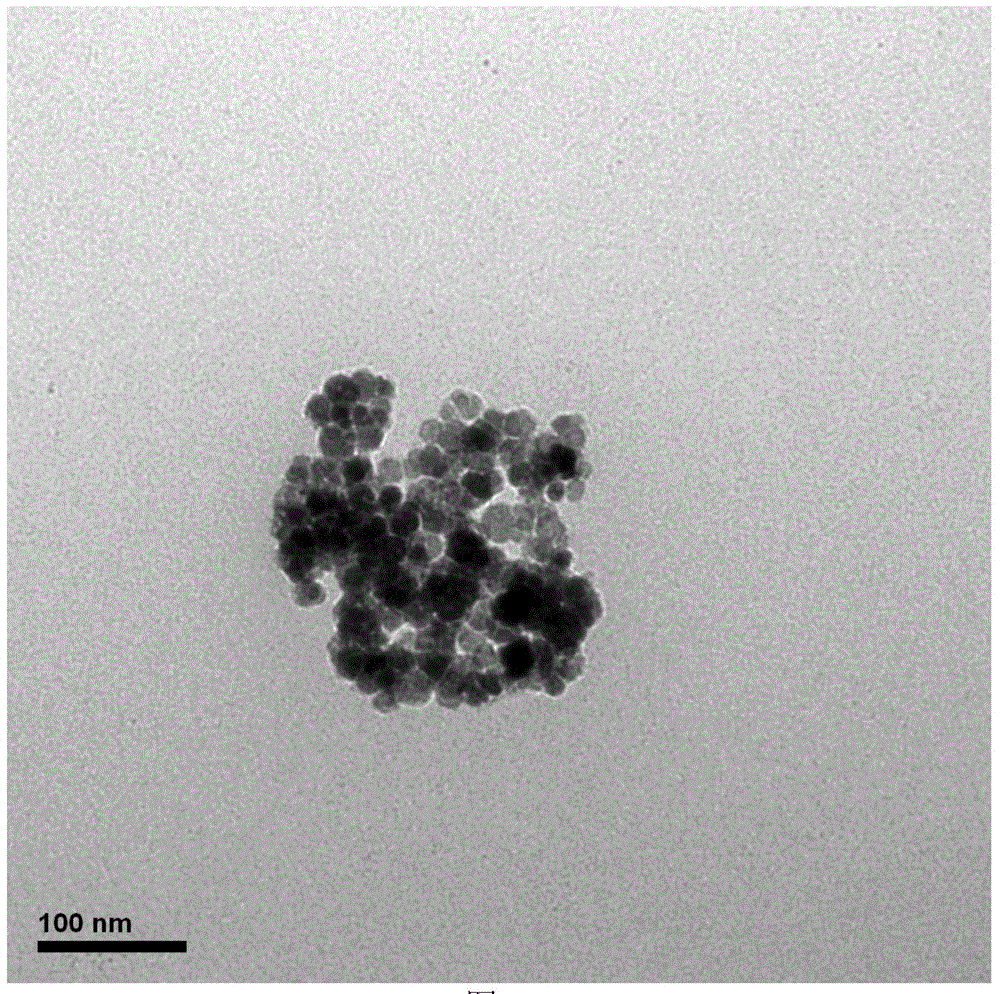

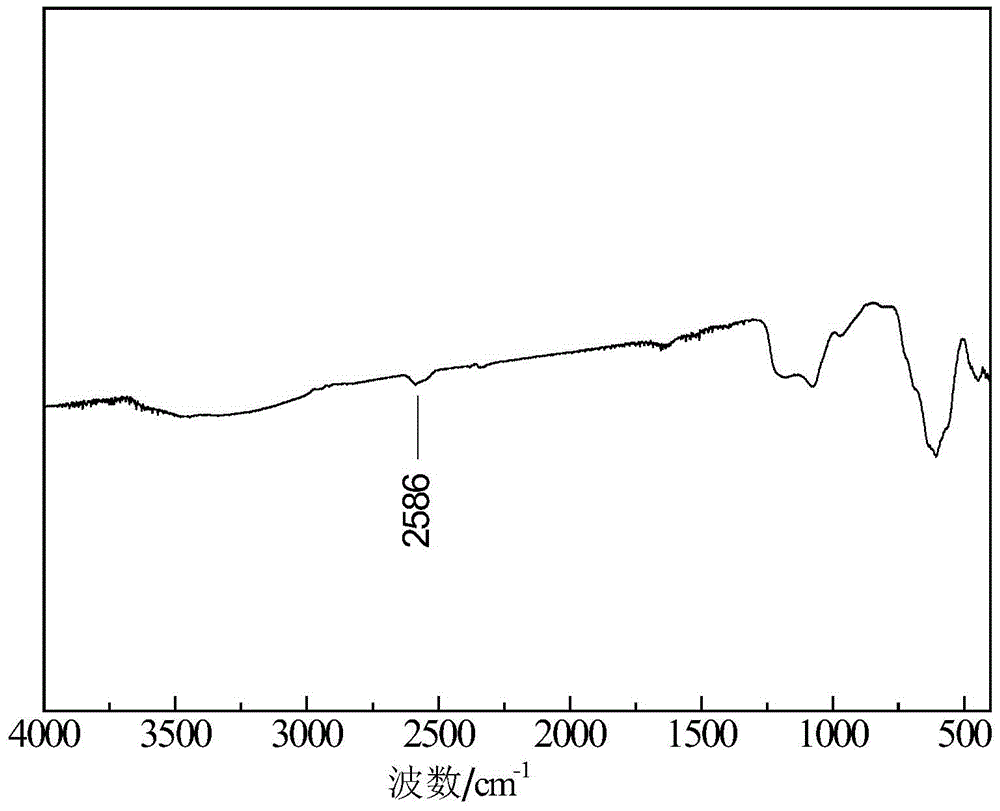

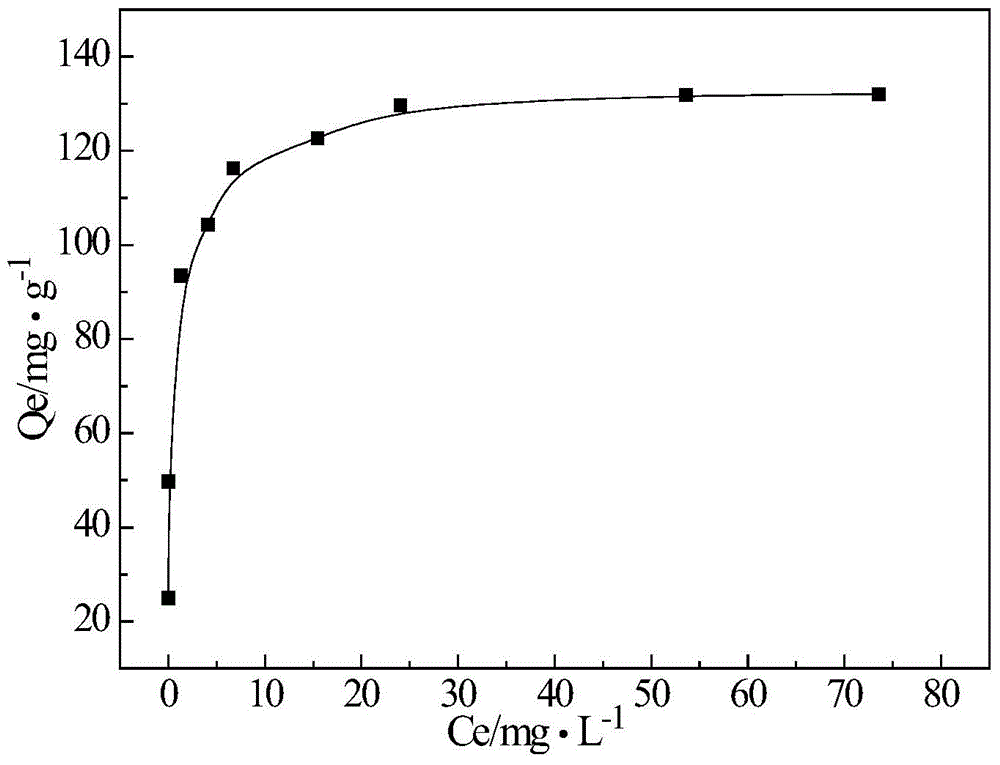

[0043] The operating steps of Examples 2-12 are the same as those in Example 1, and the raw material components and specific parameters are shown in Table 2. The mercapto-functionalized magnetic silica nanomaterial samples prepared in Examples 2-12 were characterized by transmission electron microscopy (TEM), infrared (FTIR) and other means, and used for the adsorption test of Hg(II) in simulated wastewater in the laboratory.

[0044] Table 2 The raw material components and specific parameters of Examples 1 to 12 of the present invention

[0045]

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com