A kind of preparation method of cellulose-based bactericidal emulsion

A cellulose-based, sterilizing milk technology, applied in the field of sterilizing and disinfecting daily care products, can solve the problems of unfriendly skin, difficult to prepare bactericidal emulsion, etc., achieve good bactericidal effect, save organic solvents, and save the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

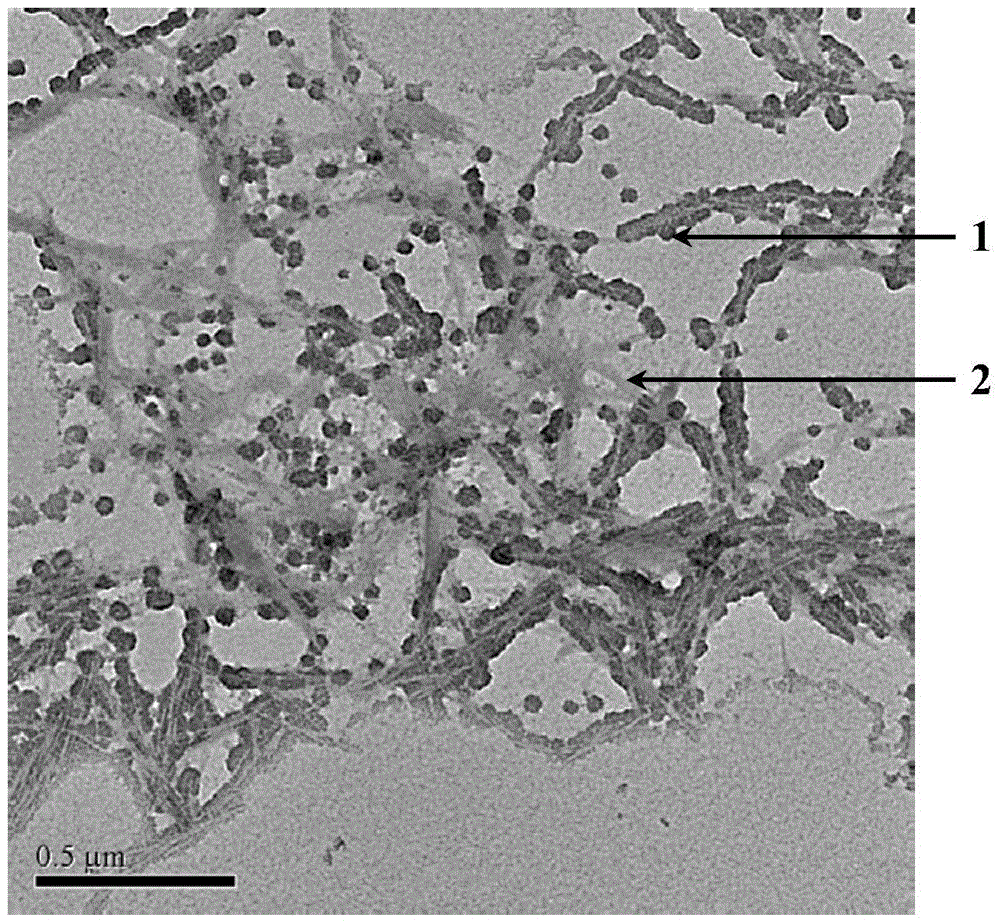

Image

Examples

Embodiment 1

[0047] A kind of preparation of cellulose-based bactericidal emulsion, its preparation operation steps are as follows:

[0048] 1) Prepare the water / organic solvent solution of the bactericide, wherein when an organic solvent is used, the amount by weight of the total amount of the emulsion is 0.01% to 0.2%

[0049] Get bactericide and join in the water / organic solvent solution, the organic solvent solution consumption of present embodiment is below 0.1%, make bactericide completely dissolve or disperse in the deionized water / organic solvent solution and prepare the water / organic solvent of bactericide solution, fungicides include triclosan, lauryl dimethylamine oxide, ammonium laureth, polyoxyethylene lauryl ammonium sulfate, 1,6-bisphenylguanidinohexane, trichlorodiphenylurea , dodecyl dimethyl benzyl ammonium chloride, benzyl ammonium p-chloro-m-xylenol, "iodine", antibiotics, biguanide salt fungicides such as alkyl biguanide salts, aryl biguanide salts and polymeric biguan...

Embodiment 2

[0058] A kind of preparation of cellulose-based bactericidal emulsion, its preparation operation steps are as follows:

[0059] One), prepare the ethanolic solution of benzyl ammonium p-chloro-m-xylenol fungicide

[0060] By mass ratio 1:3, prepare the ethanol solution of benzyl ammonium p-chloro-m-xylenol fungicide;

[0061] Two), preparation of colloidal solution of cellulose nanocrystals

[0062] Choose self-made cellulose nanocrystalline powder, its preparation process uses commercially available sulfate coniferous wood pulp board, the material concentration is controlled at 3% to 6%, react in 64.3% sulfuric acid solution at 38°C for 2.5h, dilute , centrifuged, washed with water, and dried, the cellulose nanocrystal powder obtained by weighing 2kg was added to a chemical material kettle filled with 100L deionized water, and a 2% concentration of cellulose nanocrystal homogeneous colloidal solution was prepared; The preparation process of self-made cellulose nanocrystals ...

Embodiment 3

[0070] A kind of preparation of cellulose-based bactericidal emulsion, its preparation operation steps are as follows:

[0071] One), prepare the aqueous solution of lauryl dimethyl benzyl ammonium chloride

[0072] According to mass ratio 1:5, prepare the aqueous solution of dodecyl dimethyl benzyl ammonium chloride;

[0073] Two), preparation of colloidal solution of cellulose nanocrystals

[0074] Take by weighing 3kg of commercially available cellulose nanocrystal powder, and add it into a material kettle filled with 100L deionized water to obtain a 3% concentration of cellulose nanocrystal homogeneous colloidal solution;

[0075] Three), add thickener in cellulose nanocrystal colloidal solution, surfactant thickener and surfactant add simultaneously

[0076] By weight fraction, respectively select 5 parts of carrageenan, 3 parts of secondary alkyl sulfonate sodium, 5 parts of carboxymethylcellulose sodium, join in the ethylene glycol distearate of 0.3 part, after mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com