Preparation method of nitrogen-doped titanium dioxide mesoporous visible light photocatalyst

A technology of titanium dioxide and photocatalyst, which is applied in the field of photocatalyst preparation, can solve the problems of high nitriding temperature, difficulty in obtaining high specific surface area, long reaction time, etc., and achieve the effect of high absorption coefficient and high visible light spectrum absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

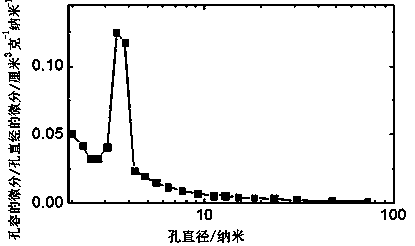

[0038] Add 0.1M hydrochloric acid ethanol solution to the ethanol solution of ethyl tetrasilicate with a volume ratio of 1:1, so that the ratio of silicon to water is 1:1, reflux at 70 degrees Celsius for 1 hour, and cool to room temperature. Then add an ethanol solution of butyl titanate with a volume ratio of 1:1, so that the ratio of the amount of Ti / Si material is 1:3. Then gradually add 0.1M ethanol solution of hydrochloric acid, so that the amount of water is twice the sum of the amounts of titanium and silicon. A gel formed after 12 hours. Dried, crushed, sieved, and calcined at 600 degrees Celsius for two hours. Weigh 2 grams after cooling, place in a tube furnace, flow rate is 1000 ml / min in flowing ammonia, nitriding at 900 degrees Celsius for 5 hours, and cool to room temperature in nitrogen protection. Weigh 2 grams, wash in 5.0M sodium hydroxide solution at 60°C for 12 hours, and dry at 110°C after washing with water. Its transmission electron microscope pictur...

Embodiment 2

[0041] Add 0.1M hydrochloric acid ethanol solution to the ethanol solution of tetraethyl orthosilicate with a volume ratio of 1:2, so that the mass ratio of silicon to water is 1:1, reflux at 70°C for 1 hour, and cool to room temperature. Then add an ethanol solution of butyl titanate with a volume ratio of 1:2, so that the ratio of the amount of Ti / Si material is 1:1. Then gradually add 0.1M ethanol solution of hydrochloric acid, so that the amount of water is twice the sum of the amounts of titanium and silicon. A gel formed after 24 hours. Dried, crushed, sieved, and calcined at 600 degrees Celsius for two hours. Weigh 2 grams after cooling, place in a tube furnace, flow rate is 1000 ml / min in flowing ammonia, nitriding at 900 degrees Celsius for 5 hours, and cool to room temperature in nitrogen protection. Weigh 2 grams, wash in 5.0M sodium hydroxide solution at 60°C for 24 hours, and dry at 110°C after washing. The absorption spectrum of the diffuse reflectance mode is...

Embodiment 3

[0044] Add 0.1M hydrochloric acid ethanol solution to the ethanol solution of tetraethyl orthosilicate with a volume ratio of 1:2, so that the mass ratio of silicon to water is 1:1, reflux at 70°C for 1 hour, and cool to room temperature. Then add an ethanol solution of butyl titanate with a volume ratio of 1:2, so that the ratio of the amount of Ti / Si material is 1:4. Then gradually add 0.1M ethanol solution of hydrochloric acid, so that the amount of water is twice the sum of the amounts of titanium and silicon. A gel formed after 24 hours. Dried, crushed, sieved, and calcined at 600 degrees Celsius for two hours. Weigh 2 grams after cooling, place in a tube furnace, flow rate is 1000 ml / min in flowing ammonia, nitriding at 900 degrees Celsius for 2 hours, and cool to room temperature in nitrogen protection. Weigh 2 grams, wash in 5.0M sodium hydroxide solution at 60°C for 24 hours, and dry at 110°C after washing. Raman spectrum such as image 3 Shown, 152.1 degrees Cels...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com