Holothurian aquaculture water modifier for removing impurities and inhibiting harmful microbe propagation with one-step method, and preparation method and application of holothurian aquaculture water modifier

A technology for cultivating water bodies and microorganisms, applied in biological water/sewage treatment, chemical instruments and methods, applications, etc., can solve the problems of ineffective purification of heavy metal ion pollution, reduction in quantity, poor adaptability of bacterial flora reproduction, etc. Good controllability of ups and downs, avoiding acidification and smelly bottom, and preventing sea cucumber diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

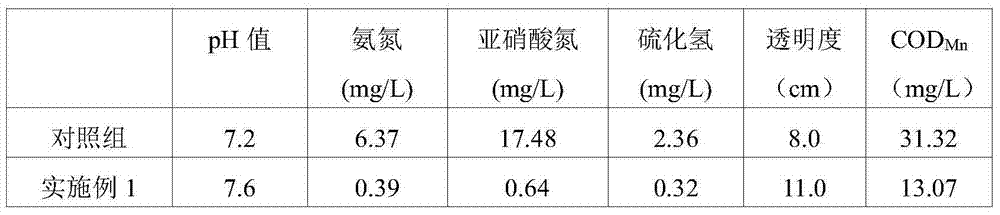

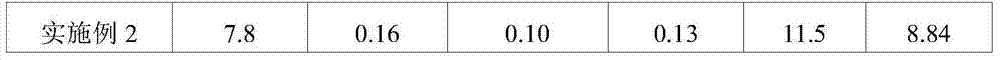

Examples

Embodiment 1

[0035] 1. Preparation of probiotic stock solution

[0036] Bacillus subtilis YB-1CGMCC No.5116, Bacillus cereus YB-2CGMCC No.5117 and Bacillus flexus XH-1CGMCC No.5115, which grew well on LB agar slant medium, were added to 2116E medium, pH7. 0~7.5, shake culture at 37℃ for 12~16h, then mix with volume ratio of 1:1:1 to prepare probiotic stock solution, the concentration of bacteria is about 1×10 8cfu / ml.

[0037] 2. Liquid fermentation culture

[0038] Add fermentation broth to the closed fermentation reactor, and add nutrients at a volume ratio of 0.1 to 1%, then inoculate the probiotic stock solution prepared in step ① at a volume ratio of 3-5%, and carry out fermentation at a pressure of 0.1~0.25Mpa, ferment at 37°C for 24 hours to obtain the fermentation product;

[0039] The above nutrients are composed of corn flour: soybean meal flour: seawater in a weight ratio of (1.5-3): (0.5-1.5): 100.

[0040] 3. Spray drying treatment

[0041] The adsorption carrier is prepa...

Embodiment 2

[0044] 1. Preparation of probiotic stock solution

[0045] Bacillus subtilis YB-1CGMCC No.5116, Bacillus cereus YB-2CGMCC No.5117 and Bacillus flexus XH-1CGMCC No.5115, which grew well on LB agar slant medium, were added to 2116E medium, pH7. 0~7.5, shake culture at 37°C for 12~16h, and then mix at a volume ratio of 1:1:1 to prepare a probiotic stock solution with a cell concentration of about 1×108cfu / ml.

[0046] 2. Liquid fermentation culture

[0047] Add fermentation broth to the closed fermentation reactor, and add nutrients at a volume ratio of 0.1 to 1%, then inoculate the probiotic stock solution prepared in step ① at a volume ratio of 3-5%, and carry out fermentation at a pressure of 0.1~0.25Mpa, ferment at 37°C for 24 hours to obtain the fermentation product;

[0048] The above nutrients are composed of corn flour: soybean meal flour: seawater in a weight ratio of (1.5-3): (0.5-1.5): 100.

[0049] 3. Spray drying treatment

[0050] The adsorption carrier is prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com