High-efficiency ocean anticorrosive paint

A marine anti-corrosion and coating technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as environmental and personal health threats, achieve high fouling release, low friction coefficient, and improve rheology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

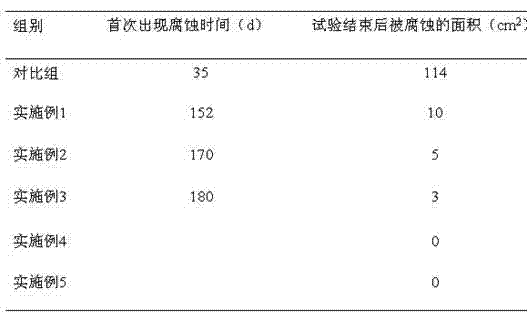

Examples

Embodiment 1

[0012] A marine high-efficiency marine anti-corrosion coating, comprising the following raw materials in parts by weight: 25 parts of fluorinated acrylate, 18 parts of silicon rubber, 1.4 parts of zinc phosphate, 0.4 parts of calcium phosphate, 0.4 parts of zinc molybdate, 0.2 parts of calcium molybdate, three Aluminum polyphosphate 0.6 parts, TiO 2 6 parts, ZnO 3 parts, CaCO 3 3 parts, SiO 2 9 parts, 0.1 part of chelating agent, 0.1 part of dispersant, 0.1 part of wetting agent.

Embodiment 2

[0014] A marine high-efficiency marine anti-corrosion coating, comprising the following raw materials in parts by weight: 40 parts of fluorinated acrylate, 33 parts of silicone rubber, 5 parts of zinc phosphate, 1 part of calcium phosphate, 1 part of zinc molybdate, 1 part of calcium molybdate, three Aluminum polyphosphate 2 parts, TiO 2 6 parts, ZnO 3.6 parts, CaCO 3 6 parts, SiO 2 8.4 parts, 1 part of chelating agent, 1 part of dispersing agent, 1 part of wetting agent.

Embodiment 3

[0016] A marine high-efficiency marine anti-corrosion coating, comprising the following raw materials in parts by weight: 30 parts of fluorinated acrylate, 22 parts of silicone rubber, 5 parts of zinc phosphate, 1 part of calcium phosphate, 1 part of zinc molybdate, 1 part of calcium molybdate, three Aluminum polyphosphate 2 parts, TiO 2 4 parts, ZnO 4 parts, CaCO 3 4 parts, SiO 2 6 parts, 0.4 parts of chelating agent, 0.4 parts of dispersing agent, 0.4 parts of wetting agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com