Preparation method of boron-doped diamond film/carbon film composite electrode material

A boron-doped diamond and composite electrode technology, which is applied in the field of preparation of conductive diamond electrodes, can solve the problems of high signal-to-noise ratio and poor charge storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

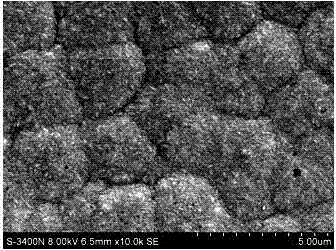

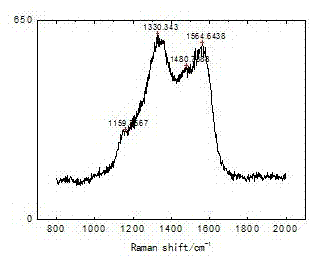

Embodiment 1

[0026] Deposit a diamond film of more than 5 μm on a 2-inch intrinsic silicon wafer. After the silicon wafer surface is cleaned by conventional methods, it is ground with diamond powder, and then the silicon wafer is cut into 15 × 5mm strips, and ultrasonically cleaned with ethanol or acetone for 5 Minutes, blow dry, place in an antenna bell jar type microwave plasma CVD reaction chamber, with the silicon side facing up, the diamond film surface is close to the abutment, the reaction chamber is evacuated, and the microwave generator is turned on. Hydrogen bubbling carries boron trioxide (B 2 o 3 ), the CH 4 / H 2 0.5vol%, B / C ratio of 1 / 100, working gas pressure of 4.3KPa, microwave output power of 1300W for 12 hours, boron-doped diamond film thickness of 5mm, four-probe test square resistance of 463Ω / □.

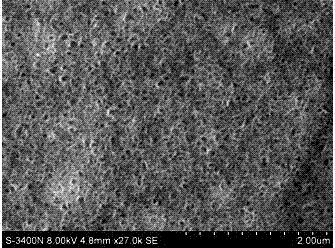

Embodiment 2

[0028]Deposit a diamond film of more than 5 μm on a 2-inch intrinsic silicon wafer. After the silicon wafer surface is cleaned by conventional methods, it is ground with diamond powder, and then the silicon wafer is cut into 15 × 5mm strips, and ultrasonically cleaned with ethanol or acetone for 5 Minutes, blow dry, place in an antenna bell jar type microwave plasma CVD reaction chamber, with the silicon side facing up, the diamond film surface is close to the abutment, the reaction chamber is evacuated, and the microwave generator is turned on. Hydrogen bubbling carries boron trioxide (B 2 o 3 ), the CH 4 / H 2 0.5vol%, B / C ratio of 1 / 100, working gas pressure of 4.3KPa, microwave output power of 1300W, the deposition time is extended to 20 hours, the boron-doped diamond film thickness is 9mm, and the square resistance of the four-probe test is 261Ω / □, enhanced conductivity.

Embodiment 3

[0030] Deposit a diamond film of more than 5 μm on a 2-inch intrinsic silicon wafer. After the silicon wafer surface is cleaned by conventional methods, it is ground with diamond powder, and then the silicon wafer is cut into 15 × 5mm strips, and ultrasonically cleaned with ethanol or acetone for 5 Minutes, blow dry, place in an antenna bell jar type microwave plasma CVD reaction chamber, with the silicon side facing up, the diamond film surface is close to the abutment, the reaction chamber is evacuated, and the microwave generator is turned on. Hydrogen bubbling carries boron trioxide (B 2 o 3 ), the CH 4 / H 2 0.5vol%, working gas pressure 4.3KPa, microwave output power 1300W for 12 hours, B / C ratio is 1 / 200, boron-doped diamond film thickness is 5mm, square resistance of four-probe test is 1464Ω / □, Conductivity drops.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com