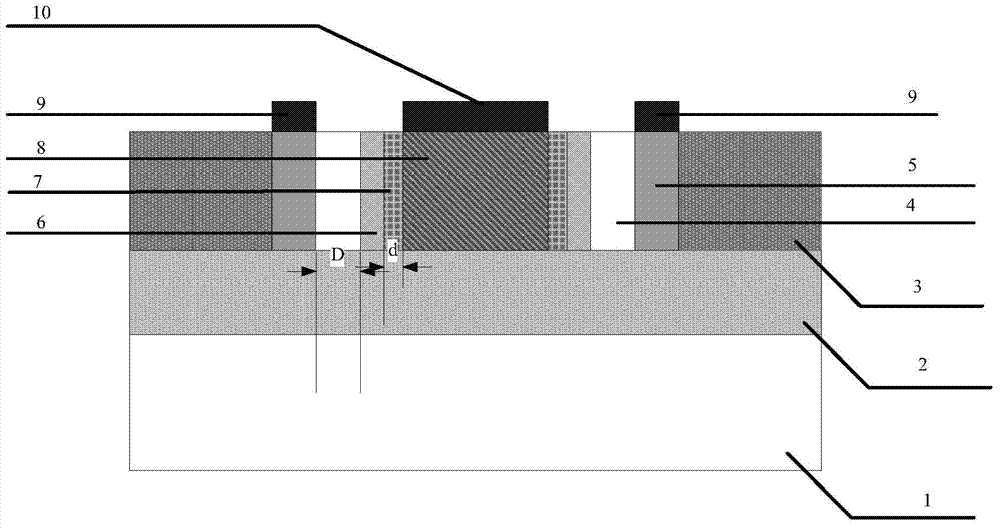

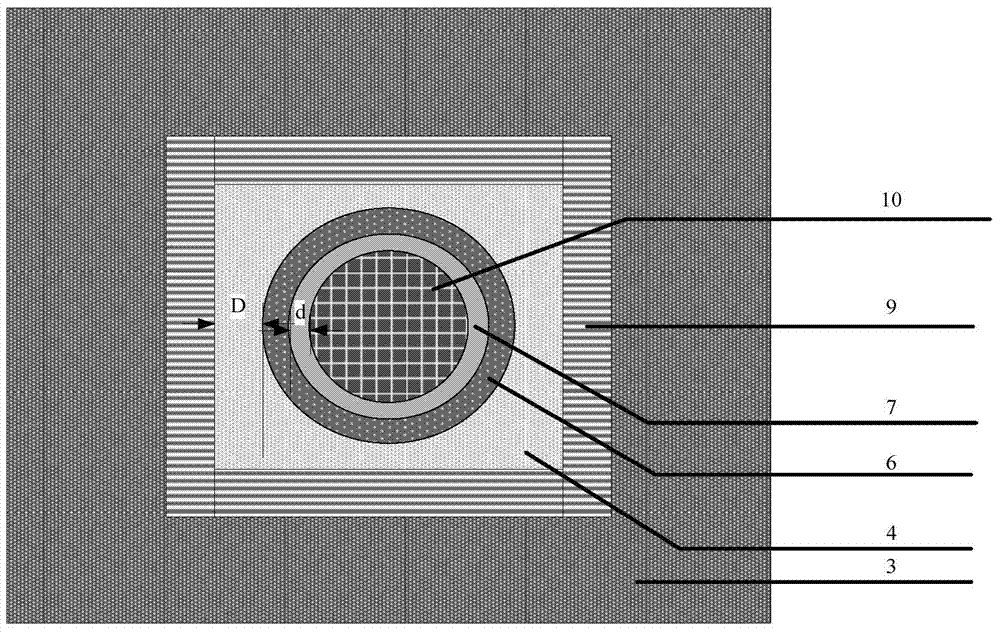

Capacitance Si-based radiation detecting device, and preparation method thereof

A radiation detector and radiation detection technology, applied in the field of microelectronics, can solve the problems of single event effect isolation, low sensitivity response, lack of protection devices, etc., and achieve the effects of reducing the working grid voltage, improving detection accuracy, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

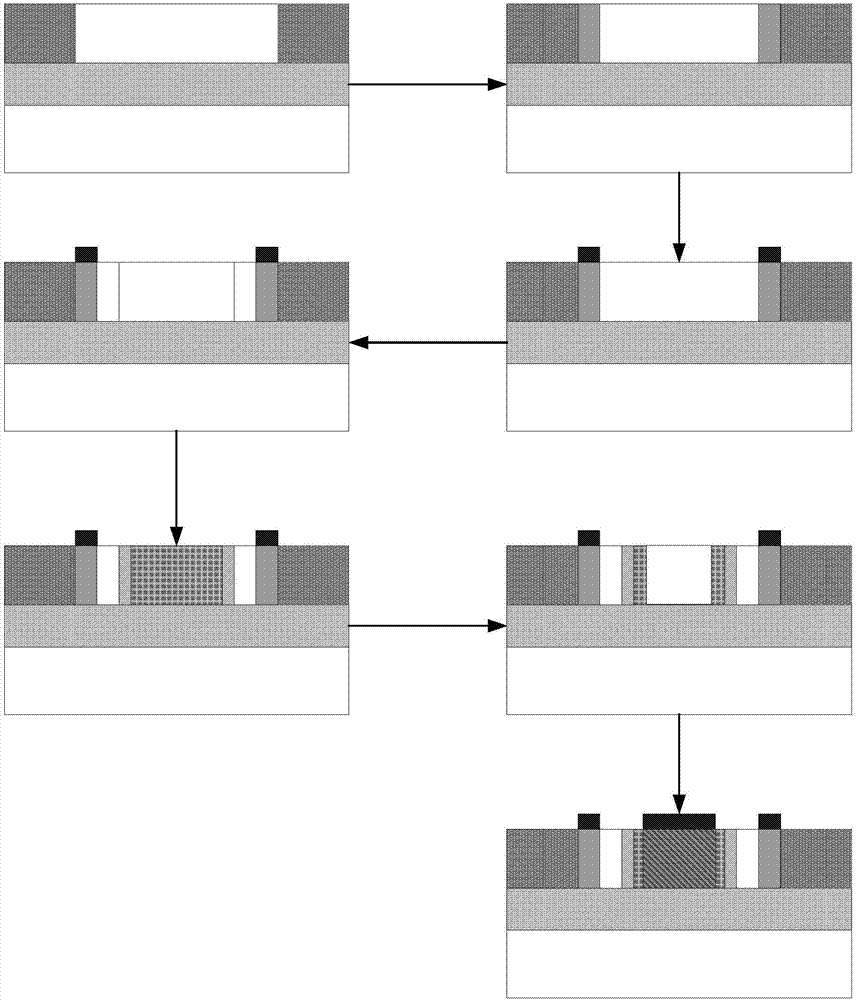

[0044] 1) On the SOI CMOS substrate, use the LOCOS process to grow an oxide isolation layer, wherein the SOI CMOS substrate includes a Si substrate layer and a buried oxide layer above the Si substrate layer.

[0045] The specific steps are: removing all oxide layers on the SOI CMOS substrate, cleaning, and growing SiO with a thickness of 50nm by dry oxygen oxidation. 2 Oxygen pad layer, in which the temperature of the oxidation furnace used is 900°C, the temperature of the oxidation bottle is 85°C, and the oxidation time is 5min; then the Si with a thickness of 220nm is grown by low-pressure chemical vapor deposition (LPCVD). 3 N 4 The masking layer, wherein the deposition pressure is 335Pa, the deposition time is 30min, and the deposition temperature is 850°C; the pattern of the oxide isolation layer is photoetched by photolithography, and the dry oxidation, wet oxidation and dry oxidation are used in sequence The method is to perform high temperature oxidation to obtain an...

Embodiment 2

[0057] 1) On the SOI CMOS substrate, use the LOCOS process to grow an oxide isolation layer, wherein the SOI CMOS substrate includes a Si substrate layer and a buried oxide layer above the Si substrate layer.

[0058] The specific steps are: removing all oxide layers on the SOI CMOS substrate, cleaning, and growing SiO with a thickness of 100nm by dry oxygen oxidation. 2 Oxygen pad layer, in which the temperature of the oxidation furnace used is 950°C, the temperature of the oxidation bottle is 88°C, and the oxidation time is 9min; then the Si with a thickness of 190nm is grown by low-pressure chemical vapor deposition (LPCVD). 3 N 4 Masking layer, wherein the deposition pressure is 32Pa, the deposition time is 55min, and the deposition temperature is 750°C; the pattern of the oxide isolation layer is photoetched by photolithography, and the dry oxidation, wet oxidation and dry oxidation are used in sequence The method is to perform high temperature oxidation to obtain an oxi...

Embodiment 3

[0070] 1) On the SOI CMOS substrate, use the LOCOS process to grow an oxide isolation layer, wherein the SOI CMOS substrate includes a Si substrate layer and a buried oxide layer above the Si substrate layer.

[0071] The specific steps are: remove all oxide layers on the SOI CMOS substrate, clean, and grow SiO with a thickness of 150nm by dry oxygen oxidation. 2 Oxygen pad layer, in which the temperature of the oxidation furnace used is 1000°C, the temperature of the oxidation bottle is 90°C, and the oxidation time is 7 minutes; then the Si with a thickness of 210nm is grown by low-pressure chemical vapor deposition (LPCVD). 3 N 4 Masking layer, wherein the deposition pressure is 29Pa, the deposition time is 50min, and the deposition temperature is 800°C; the pattern of the oxide isolation layer is photoetched by photolithography, and the dry oxidation, wet oxidation and dry oxidation are used in sequence The method is to perform high temperature oxidation to obtain an oxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com