Preparation method and application of polyisophthaloyl metaphenylene diamine-polyacrylonitrile composite nanofiber film

A technology of polym-phenylene isophthalamide and composite nanofibers, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., and can solve problems such as difficult recycling, low mechanical strength, and cumbersome immobilized enzyme process , to achieve the effects of easy recycling, high mechanical strength, and improved utilization of enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

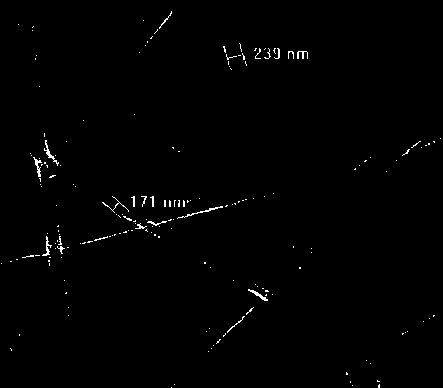

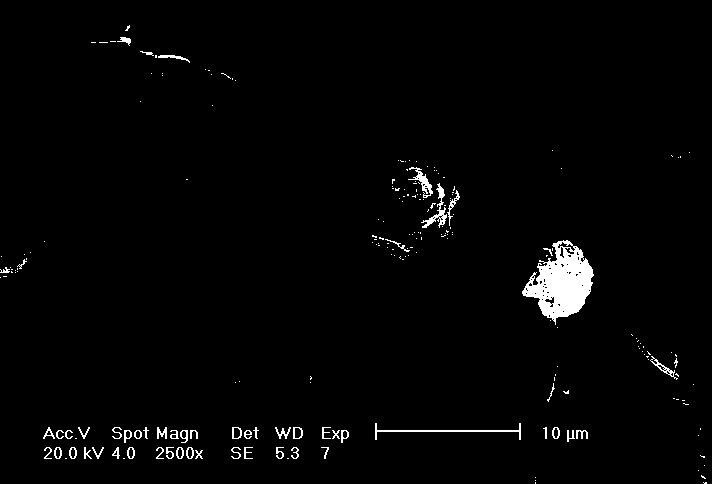

[0030] 1. Dissolving the polym-phenylene isophthalamide polymer in N,N-dimethylacetamide solution (containing 8% lithium chloride by mass percentage) to form a solution with a mass percentage of 5%, Dissolve polyacrylonitrile in N,N-dimethylacetamide solution to prepare a 5% solution by mass. The above-mentioned polym-phenylene isophthalamide and polyacrylonitrile solution were blended to form a solution with a mass ratio of 1:3, and injected into the electrospinning device. Electrospinning was carried out under the conditions of a voltage of 16 kV, a spinneret solution flow rate of 1 mL / h, a receiving distance of 10 cm, and a drum rotation speed of 200 r / min to obtain polyresorcinol with a fiber diameter of about 200 nm. For m-phenylenediamine formamide-polyacrylonitrile nanofiber membrane, the nanofiber membrane was immersed in distilled water for 2 h, and the membrane was taken out and dried in a vacuum oven at 80°C for 12 h. figure 1 Shown is the SEM characterization di...

Embodiment 2

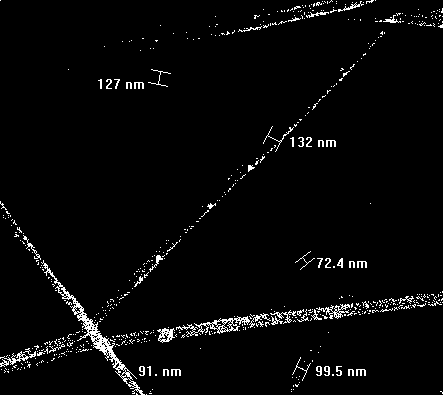

[0033] 1. Dissolve polym-phenylene isophthalamide polymer in N,N-dimethylacetamide solution (containing 10% lithium chloride by mass percentage) to form a 5% solution by mass, Dissolve polyacrylonitrile in N,N-dimethylacetamide solution to prepare a 5% solution by mass. The above-mentioned polym-phenylene isophthalamide and polyacrylonitrile solution were blended to form a solution with a mass ratio of 3:1, and injected into the electrospinning device. Electrospinning was carried out under the conditions of a voltage of 16 kV, a spinneret solution flow rate of 0.5 mL / h, a receiving distance of 10 cm, and a drum rotation speed of 500 r / min to obtain polymethane with a fiber diameter of about 100 nm. Diformyl m-phenylenediamine-polyacrylonitrile nanofiber membrane, immerse the nanofiber membrane in distilled water for 2 h, take out the membrane and dry it in a vacuum oven at 60°C for 12 h. figure 2 Shown is the SEM characterization of the prepared composite nanofibrous membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com