Environment-friendly cooling liquid for diamond wire cutting and preparation method thereof

A diamond wire cutting and cooling liquid technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of redness, dry skin, etc., and achieve the effects of low comprehensive cost, convenient and economical waste liquid treatment, and not easy to spoil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

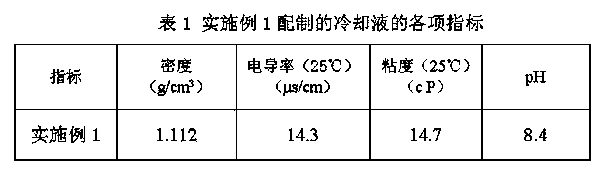

[0022] Embodiment 1: Weigh 7kg of triethanolamine oleate, 1kg of polyethylene glycol, 3kg of borax, 13kg of triethanolamine borate, 5kg of dodecenylsuccinic acid diethanolamide, 2kg of fatty alcohol polyoxyethylene ether, polyoxyethylene Ethylene polyoxypropanolamine ether 0.02kg, deionized water 68.98kg.

[0023] In deionized water, while stirring constantly, add the described triethanolamine oleate, polyethylene glycol, borax, triethanolamine borate, dodecenylsuccinic acid diethanolamide, fatty alcohol polyoxyethylene ether successively 1. Polyoxyethylene polyoxypropanolamine ether, continue to stir for 3h, and obtain 100kg of the environment-friendly cooling liquid for diamond wire cutting after filtering through filter paper.

[0024] The tested indicators of the environment-friendly diamond wire cutting coolant prepared in this example are shown in Table 1 below.

[0025]

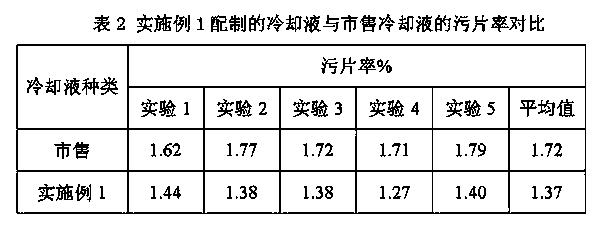

[0026] Under the same cutting parameters, the environment-friendly diamond wire cutting coolant...

Embodiment 2

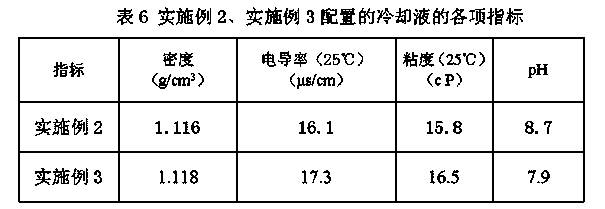

[0036] Embodiment 2: Take by weighing oleic acid triethanolamine 6kg, polyammonium methacrylate 4kg, polyethylene glycol 1kg, triethyl phosphate 1kg, borax 3kg, sodium silicate 1kg, triethanolamine borate 16kg, dodecenyl Succinic acid diethanolamide 4kg, sodium benzoate 4kg, fatty alcohol polyoxyethylene ether 2kg, sodium dodecylbenzenesulfonate 2kg, polyoxyethylene polyoxypropanolamine ether 0.02kg, simethicone 0.02kg, 55.96kg of ionized water.

[0037] In deionized water, while constantly stirring, add the described triethanolamine oleate, ammonium polymethacrylate, polyethylene glycol, triethyl phosphate, borax, sodium silicate, triethanolamine borate, dodecyl Alkenyl succinic acid diethanolamide, sodium benzoate, fatty alcohol polyoxyethylene ether, sodium dodecylbenzenesulfonate, polyoxyethylene polyoxypropanolamine ether, dimethyl silicone oil, continue to stir for 3 hours, and filter through filter paper Afterwards, 100 kg of cooling liquid for the environment-friendly...

Embodiment 3

[0038] Embodiment 3: take by weighing oleic acid triethanolamine 5kg, polyammonium methacrylate 3kg, polyvinylpyrrolidone 2kg, polyethylene glycol 1kg, triethyl phosphate 0.5kg, oleic acid 0.5kg, borax 2kg, sodium silicate 2kg, triethanolamine borate 16kg, dodecenyl succinic acid diethanolamide 4kg, sodium benzoate 4kg, fatty alcohol polyoxyethylene ether 1kg, sodium dodecylbenzenesulfonate 3kg, polyoxyethylene polyoxypropanol Amino ether 0.01kg, simethicone 0.03kg, deionized water 55.96kg.

[0039]In deionized water, while stirring continuously, add the triethanolamine oleate, ammonium polymethacrylate, polyvinylpyrrolidone, polyethylene glycol, triethyl phosphate, oleic acid, borax, sodium silicate in sequence , triethanolamine borate, dodecenyl succinic acid diethanolamide, sodium benzoate, fatty alcohol polyoxyethylene ether, sodium dodecylbenzenesulfonate, polyoxyethylene polyoxypropanolamine ether, dimethyl Silicone oil, continue to stir for 3 hours, and obtain 100 kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com