Graphene oxide loaded magnetic iron gold adsorption/photocatalyst, and preparation method and application thereof

A photocatalyst and graphene technology, applied in the field of water treatment, can solve the problems of high toxicity of toxic organic wastewater, unsatisfactory effect, and poor biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

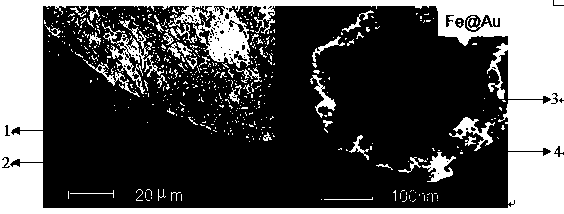

Image

Examples

Embodiment 1

[0024] A preparation method for the base magnetic iron gold adsorption / photocatalyst supported by graphite oxide, comprising the following steps:

[0025] 1) Preparation of iron / gold core-shell nanoparticles: add 20mL, 0.1M ascorbic acid solution to 4mL, 0.01M Fe(NO 3 ) 3 In the solution, react in a nitrogen environment for 20min, adjust the pH to 4.0, add 4mL, 0.01M HAuCl 4 The solution was reacted for 1 hour, and the product was separated by a magnet, washed with water, and dried under vacuum at 25°C.

[0026] 2) Preparation of graphene oxide: add 25mL, 98% concentrated sulfuric acid solution, 5g K 2 S 2 o 8 Solid, 5g P 2 o 5 Solid, 5g of graphite, heated to 80°C and maintained for 6 hours, then cooled to 20°C, diluted with 1L of ultrapure water, and allowed to stand for 12 hours. Filter the oxidized graphite and wash it with pure water, dilute it with 250mL, 98% concentrated sulfuric acid solution below 0°C, add 30g KMnO 4 Solid, heat the flask to 35°C, keep it for...

Embodiment 2

[0030] Use the iron / gold core-shell nano-catalytic material prepared in Example 1 to catalytically degrade 4-NP: take 25mL of NaHB with a concentration of 0.06mol / L 4 Solution, placed in a 250mL Erlenmeyer flask, add 100mL concentration to 1.0×10 -4mol / L 4-NP solution, and then add 5 mL of the iron / gold core-shell nanocatalyst material prepared in Example 1 with a concentration of 1.4 g / L to adjust the pH to 7.2. The mixed system was kept in the dark for 30 min at room temperature to achieve adsorption-desorption equilibrium. Turn on the xenon light source, use a cut-off filter to obtain visible light with a wavelength of 400nm, take samples regularly and use a shimadzu UV2550 ultraviolet / visible spectrophotometer with a diode array detector to measure 4-NP in the solution.

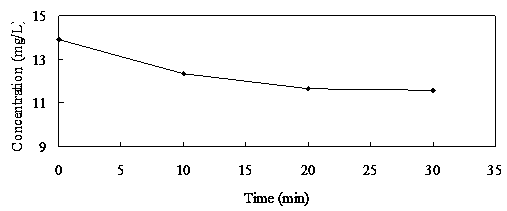

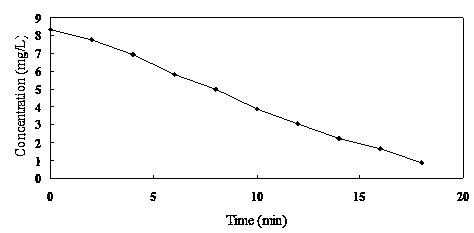

[0031] Taking graphene oxide as a control, the results are as follows figure 2 and image 3 as shown, figure 2 is the adsorption equilibrium diagram of graphene oxide on 4-NP, image 3 It is the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com