Modified lectin wrapped magnetic macromolecular liposome nano microsphere, preparation method and application

A technology of nano-microspheres and magnetic nanoparticles, which is applied in the field of magnetic macromolecular liposome nano-spheres, preparation and application of modified lectin, which can solve the problem of difficulty in maintaining antibody activity, insufficient stability, and low grafting efficiency and other problems, to achieve the effect of convenient preparation and separation, simple preparation method, and strong tumor targeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Preparation of lentil lectin-hexadecyltrimethylammonium chloride

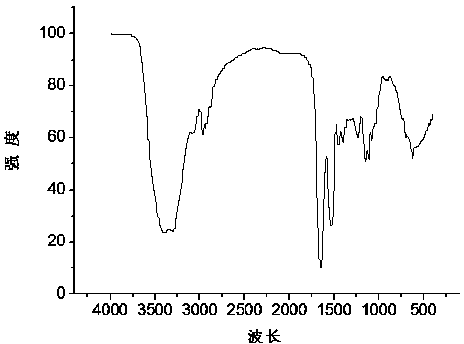

[0046] Dissolve 10 mg of lentil agglutinin (LCA) in 10 ml of a mixed solution of deionized water and isopropanol (the volume ratio of water and isopropanol is 1:1); Add 100 mg of ammonium chloride slowly to the system; adjust the pH value between 7.0 and 12.0 with NaOH, stir at room temperature for 24 hours, dialyze the reaction solution with deionized water for 3 days, and freeze-dry to obtain lentil agglutinin-ten White powder of hexaalkyl quaternary ammonium salt (LCA-HQ) 12.0mg. Depend on figure 1 It can be seen that both the characteristic absorption peaks of lentil lectin and hexadecyl quaternary ammonium salt exist, indicating that the lentil lectin-hexadecyl quaternary ammonium salt has been successfully prepared.

[0047] Among them, dimethyl hexadecyl epoxypropyl ammonium chloride can be replaced by other long-chain alkyl quaternary ammonium salts, and other long-chain alkyl quatern...

Embodiment 2

[0048] Example 2 Effects of different ratios of lentil lectin-hexadecyl quaternary ammonium salt (LCA-HQ) and cholesterol on the particle size of lentil lectin macromolecular liposomes when using the reverse evaporation method

[0049] Dissolve LCA-HQ and cholesterol in different proportions in dichloromethane, and mix well to obtain solution I; prepare deionized aqueous solution II, in which the ratio of solution I and solution II is 1:2; after mixing the two solutions, Sufficient ultrasonic emulsification, dichloromethane was distilled off under reduced pressure on a rotary evaporator to obtain a lentil lectin macromolecular liposome solution. As can be seen from Table 1, adjusting the mass ratio of LCA-HQ and cholesterol can obtain lentil lectin macromolecular liposomes with different particle sizes, and the particle size distribution of the lentil lectin macromolecular liposomes in aqueous solution is also the same. are relatively uniform.

[0050]

Embodiment 3

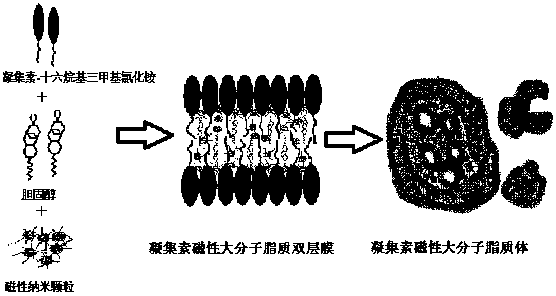

[0051] Example 3 Preparation of magnetic macromolecular liposomes encapsulated by lentil lectin

[0052] (1) Fe 3 o 4 Preparation of Magnetic Nanoparticles

[0053] Configure FeSO with a mass concentration of 1.0% to 20.0% 4 ·7H 2 O and FeCl 3 A blend of FeSO 4 ·7H 2 O and FeCl 3 The mass ratio of the mixture is 1-2:1, and mechanically stirred under the condition of N2 gas. After mixing, add ammonia water with a mass concentration of 25.0%. %, then add oleic acid with a concentration of 1.0% to 10.0% of the total mass of the entire reaction system, continue to stir and react at room temperature for 3 to 10 hours, then stop the reaction, and obtain Fe after magnetic separation 3 o 4 magnetic nanoparticles. Prepared Fe 3 o 4 The particle size of magnetic nanoparticles is 15.0nm, has superparamagnetism, and the saturation magnetization is 30.0emu / g; where Fe 3 o 4 The magnetic nanoparticles can be replaced by other yttrium ferrite magnetic fluids, cobalt nanopart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com