Treatment method of 1,3-propanediol production wastewater

A technology for the production of waste water and treatment methods, which is applied in the directions of water/sewage multi-stage treatment, heating water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problems of difficult adaptation, high treatment cost, high concentration and high salt content organic waste water no problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

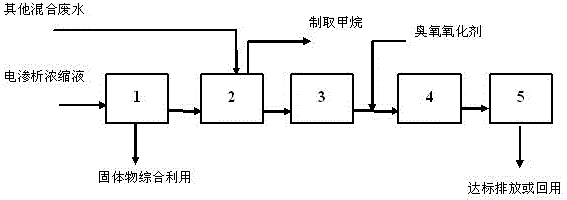

Image

Examples

Embodiment 1

[0031] The 1,3-propanediol production wastewater is treated by the treatment method of the invention. The waste water is produced from crude glycerin, the main by-product of the biodiesel industry, using crude glycerol substrate fermentation, plate and frame filtration, ultrafiltration, electrodialysis, membrane evaporation, crude distillation and rectification to produce the final product1 ,3-Propanediol is produced in the process. The waste water produced mainly includes tank washing water in the fermentation process, filter cloth washing water in the plate and frame filtration process, membrane cleaning liquid in the membrane filtration process, concentrated liquid in the electrodialysis separation process, distillate in the distillation process, etc. Among them, the concentrated solution discharged from the electrodialysis separation process is a kind of high-concentration, high-salt organic wastewater, and its discharge accounts for about 25wt% of the total wastewater dis...

Embodiment 2

[0037] The treatment device of Example 1 was used to treat the same sewage as in Example 1, and the wastewater treatment effects obtained by changing the operating conditions of each treatment unit are shown in Table 2.

[0038] Table 2 Main processing unit composition and processing effect of embodiment 2

[0039] Handling unit name Processing device scale and main components Main operating conditions and control parameters Treatment effluent or effect 1 Multi-effect evaporation Falling film five-effect evaporation test device, made of glass. The wastewater treatment scale of the device is 50mL / h, mainly including evaporation column, preheater, condenser and enamel crystallization tank Continuous operation, the external steam supply is 0.4MPa saturated steam, the consumption is 18g / h; the evaporation water volume of each effect is 12.2, 10.3, 8.7, 7.6, 6.2mL / h; the concentrated solution is 5.0mL / h, and the circulating water is used to cool and crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com