Preparation method for lithium titanate material membrane electrode

A material film, lithium titanate technology, used in electrode manufacturing, battery electrodes, electrode heat treatment, etc., can solve the impact of battery compaction density and DC internal resistance, the adhesion between the dressing and the metal foil bottom, and the bonding performance. and other problems, to achieve the effect of saving conductive metal substrate, short synthesis process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

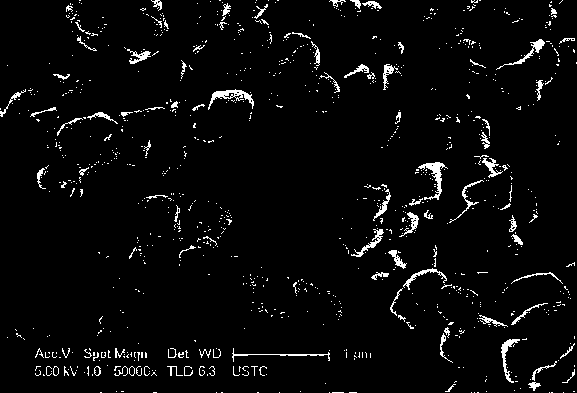

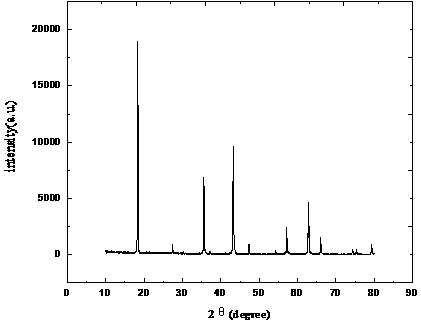

Image

Examples

Embodiment 1

[0027] Weigh lithium carbonate and titanium dioxide according to the molar ratio of lithium and titanium elements of 0.84:1, use analytical pure absolute ethanol as solvent, and the addition amount is 10% of the solid content of the control slurry; add triethyl phosphate as dispersant, the addition amount 2% of the total mass of the material; add polyvinyl butyral as a binder, and the amount added is 8% of the entire slurry volume; add polyethylene glycol as a plasticizer, and the amount added is 6% of the slurry volume ; Add SP as conductive agent, the amount added is 30% of the total material mass. Control the ball-to-material ratio of zirconium balls to 6:1, the speed to 450r / min, ball mill for 5 hours, adjust the slurry to 3000cp after ball milling, and evenly coat the smooth board surface with a small knife coater, and the coating thickness is 10μm , slightly dried in the air to obtain a precursor film with a certain toughness.

[0028] Use a slicer to take the slices, p...

Embodiment 2

[0031] Lithium hydroxide and titanium dioxide are weighed according to the molar ratio of lithium and titanium elements being 0.9:1, and analytically pure acetone is used as a solvent, and the addition amount is 60% of the solid content of the slurry to be controlled; ammonium salt dispersant 6300 is added as a dispersant, and the addition amount is 0.5% of the total mass of the material; add polyvinyl alcohol as a binder, and its addition is 1% of the total slurry volume; add dibutyl phthalate as a plasticizer, and its addition is 1% of the slurry volume; Add KS-6 as conductive agent, the amount added is 5% of the total material mass. Control the ball-to-material ratio of zirconium balls to 4:1. The rotation speed is 450r / min, the ball mill is 5h, the slurry is adjusted to 4000cp after the ball mill, and the small knife coater is evenly coated on the smooth board surface, the coating thickness is 10μm, and the precursor with certain toughness is obtained by drying in the air ...

Embodiment 3

[0034] Weigh lithium acetate and titanium dioxide according to the molar ratio of lithium and titanium elements of 0.84:1, use analytically pure acetone as a solvent, and add 20% of the solid content of the slurry; add ammonium salt dispersant OP-85 as a dispersant, the amount It is 1% of the total mass of the material; adding polyvinyl alcohol as a binder, and its addition is 4% of the entire slurry volume; adding diethylene glycol dibenzoate as a plasticizer, and the addition is 4% of the slurry volume %; Add KS-6 as conductive agent, the amount added is 20% of the total material mass. Control the ball-to-material ratio of zirconium balls to 3:1. The rotation speed is 450r / min, the ball mill is 5h, the slurry is adjusted to 1000cp after the ball mill, and the small knife coater is evenly coated on the smooth board surface, the coating thickness is 10μm, and the precursor with certain toughness is obtained by drying slightly in the air. body membrane.

[0035] Use a slicer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com