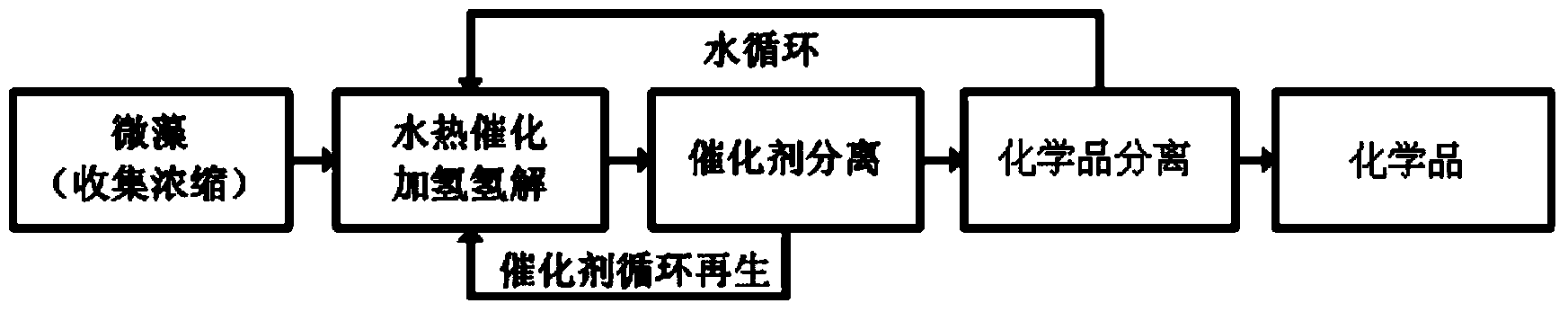

Method for preparing chemical products by direct hydrothermal hydrogenation of microalgae

A hydrothermal hydrogenation and chemical technology, which is applied in chemical instruments and methods, organic chemistry, carbon-based compound preparation, etc., can solve the problems of long time, high price and high cost of enzymatic hydrolysis and saccharification, and achieve easy cultivation, The effect of high conversion rate and short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The experiments were carried out in a Parr autoclave with a volume of 100ml and operated in batch mode. First add 0.5g of Scenedesmus and 50ml of deionized water into the reactor, the solid-to-liquid ratio is 1g:100mL, wherein the carbohydrate content of Scenedesmus is 60.15% (mass percentage), N content: 0.006% (mass percentage), S content: 0.08% (mass percentage). After adding 0.15g of hydrogenation catalyst (catalyst with hydrogenation and hydrogenolysis activity), seal the reaction kettle, pass high-purity hydrogen to replace the air in the kettle, and keep the initial partial pressure of hydrogen at 4MPa, and control the stirring speed at 600r / min . After the heating starts, the temperature rises to 280°C at a rate of 15K / min, reacts for 30 minutes, stops heating, and after cooling to room temperature, carefully collects the reaction product, and separates the liquid phase product and the solid catalyst by centrifugation. After filtering through the filter head, ...

Embodiment 2

[0031] The specific implementation process is the same as in Example 1, except that 10g of Scenedesmus and 50ml of deionized water are added, the solid-to-liquid ratio is 20g:100mL, and 2.0g of hydrogenation catalyst is added at the same time; the reaction temperature is stabilized at 250°C, and the reaction time is extended to 2h , the initial hydrogen partial pressure was set at 8MPa.

[0032] After the reaction, the product analysis showed that the hydrothermal conversion rate of Scenedesmus reached 100%, among which, the yield of 1,2-propanediol reached 9.32%, ethylene glycol was 7.86%, and acetol was 30.66%.

Embodiment 3

[0034]The specific implementation process is the same as in Example 1, except that the added raw material is chlorella, the carbohydrate content of chlorella is 50.24%, the N content: 0.008%, and the S content: 0.07%. The quality of the added chlorella was 5g, the deionized water was 50ml, the solid-to-liquid ratio was 10g:100mL, and a hydrogenation catalyst with a mass of 1.0g was added at the same time; The pressure is set at 6MPa.

[0035] After the reaction, product analysis revealed that the hydrothermal conversion rate of Chlorella reached 78.36%, of which, the yield of 1,2-propanediol reached 10.34%, that of ethylene glycol was 13.46%, and that of acetol was 35.42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com