Amide monolithic column for enriching glycopeptide based on hydrophilic interaction mechanism and preparation and application method thereof

A technology of hydrophilic interaction and monolithic column, which is applied in the preparation of test samples, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as synthesis process or cumbersome operation process, achieve stable and uniform structure, and improve selectivity , Preparation is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Preparation of amide-type monolithic column

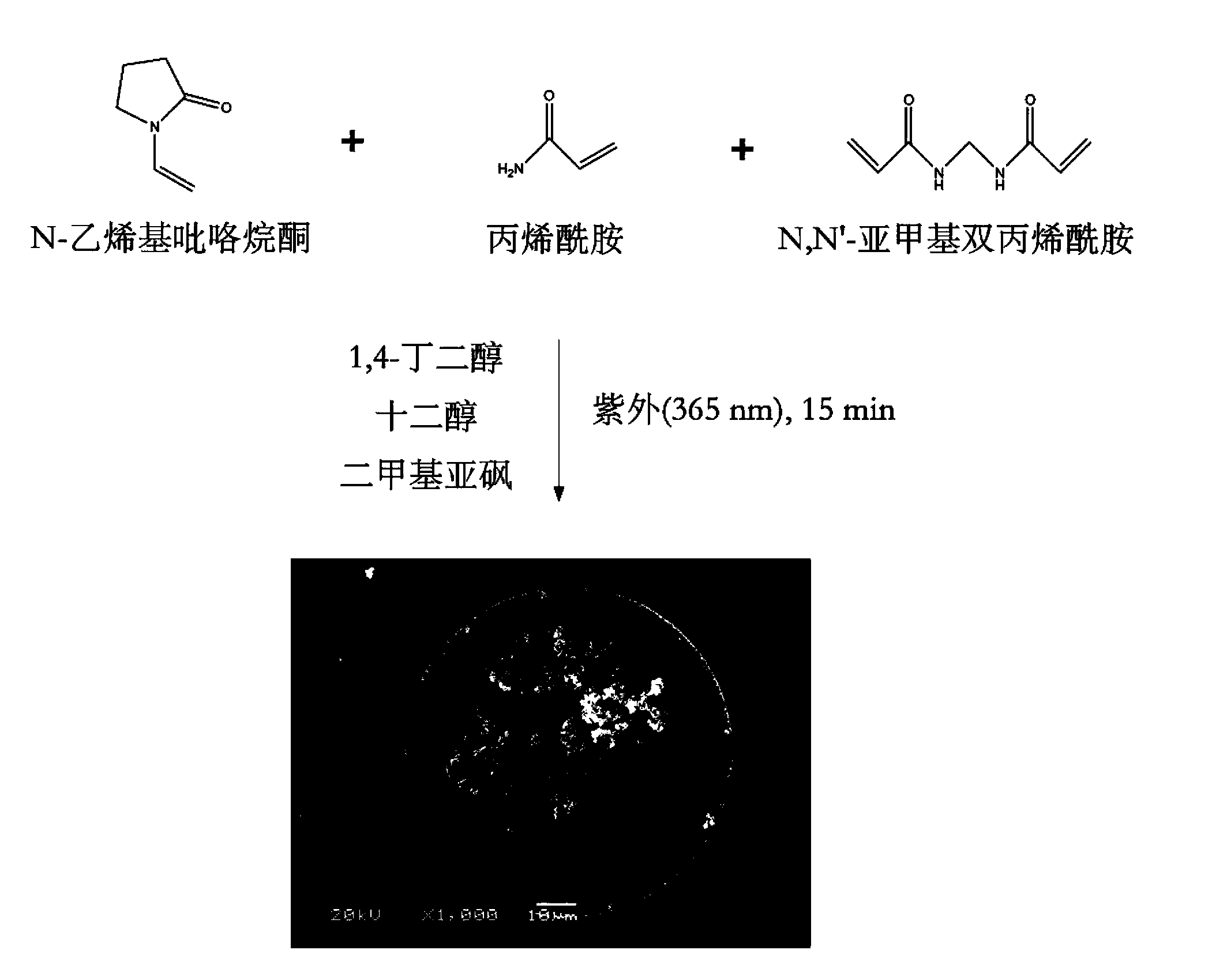

[0029] Such as figure 1 As indicated, weigh 11.5mg of acrylamide, 22.2mg of N-vinylpyrrolidone and 56mg of N,N'-methylenebisacrylamide, add 420μL of dimethyl sulfoxide, shake to dissolve until clear, then add 0.9mg of azo Diisobutyronitrile, mixed until clear; add 0.15g of 1,4-butanediol and 0.3g of dodecanol, after mixing evenly, pass through N 2 30 seconds to remove O from the solution 2 , The solution was poured into a 12 cm long ultraviolet transparent quartz capillary, and both ends were sealed with silica gel. Under the irradiation of 365nm ultraviolet light, react for 15min. Take out the capillary, and pass through acetonitrile for about 1 hour to remove unreacted substances, thereby preparing an amide-type monolithic column.

[0030] 2. Internal characterization of monolithic column materials

[0031] Scanning electron microscope picture as figure 2 As shown, the prepared monolithic column has a stable and ...

Embodiment 2

[0033] 1. Standard protein sample pretreatment

[0034] Weigh 1mg of human serum immunoglobulin (IgG) and dissolve it in 1mL of 20mM ammonium bicarbonate solution, heat the reaction at 90°C for 10min, cool to room temperature, then add 4μL of 1M dithiothreitol solution (prepared with 20mM ammonium bicarbonate solution) , heated at 56°C for 1.5 h; after cooling to room temperature, 8 μL of 1M iodoacetamide solution (prepared with 20 mM ammonium bicarbonate solution) was added, and reacted at room temperature for 40 min in the dark. After the reaction, add 40 μL of 1 mg / mL trypsin solution (prepared with 20 mM ammonium bicarbonate solution), heat the reaction at 37 ° C for 20 h, then add an appropriate amount of formic acid (FA) to make the pH of the solution around 2-3 to terminate the reaction, and finally A 1 mg / mL standard proteolysis product was obtained.

[0035] A C18 pre-column was used to desalt and lyophilize the above enzymatic hydrolyzate, and finally the sample was...

Embodiment 3

[0041] 1. Selective enrichment of glycopeptides under the interference of BSA hydrolyzate

[0042] Mix the prepared 1 mg / mL IgG and BSA hydrolyzate (dissolved in 80% ACN containing 0.1% FA) at a mass ratio of 1:1 and 1:100000, cut off a 10 cm amide-type monolithic column, and load 2 μL of the above standard The mixed solution of proteolysis products was washed with 80% ACN (containing 0.1% FA) for 30 minutes, and then the glycopeptides were eluted for 10 minutes under the condition of 70% ACN (containing 0.1% FA), and the eluted enriched products were collected. Direct MALDI-TOF MS analysis.

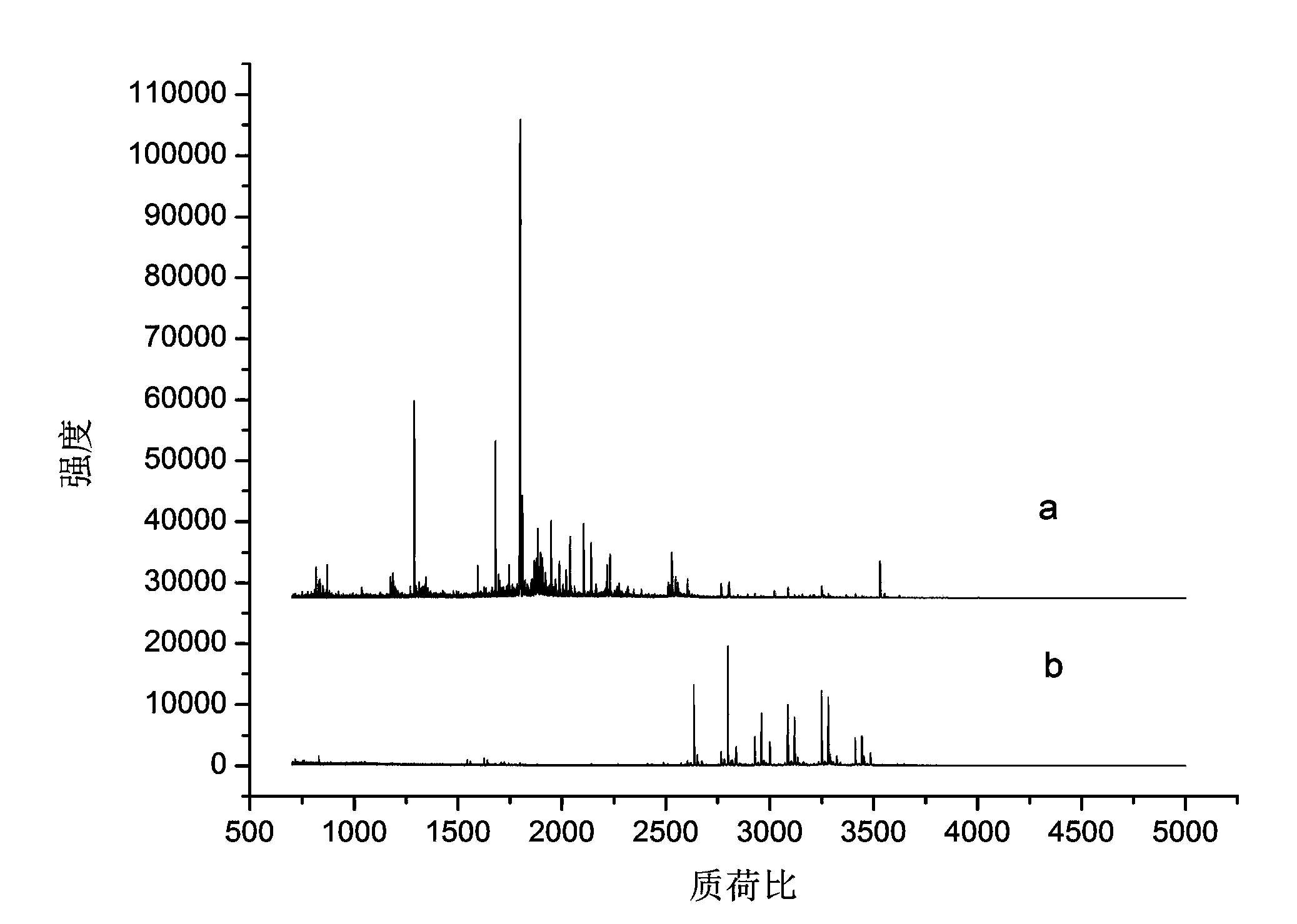

[0043] 2. MALDI-TOF MS analysis

[0044] 1 μL of the enriched product and 1 μL of LDHB matrix (20 mg / mL DHB dissolved in 60% acetonitrile solution containing 0.1% trifluoroacetic acid) were sequentially spotted on the MALDI target plate, and the mass spectrometric identification was carried out after the sample spot was dried. Such as Pic 4-1 , 4-2 and Figure 5-1 , 5-2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com